6.5 FUNCTION BUTTONS (CUTTING FLOW)

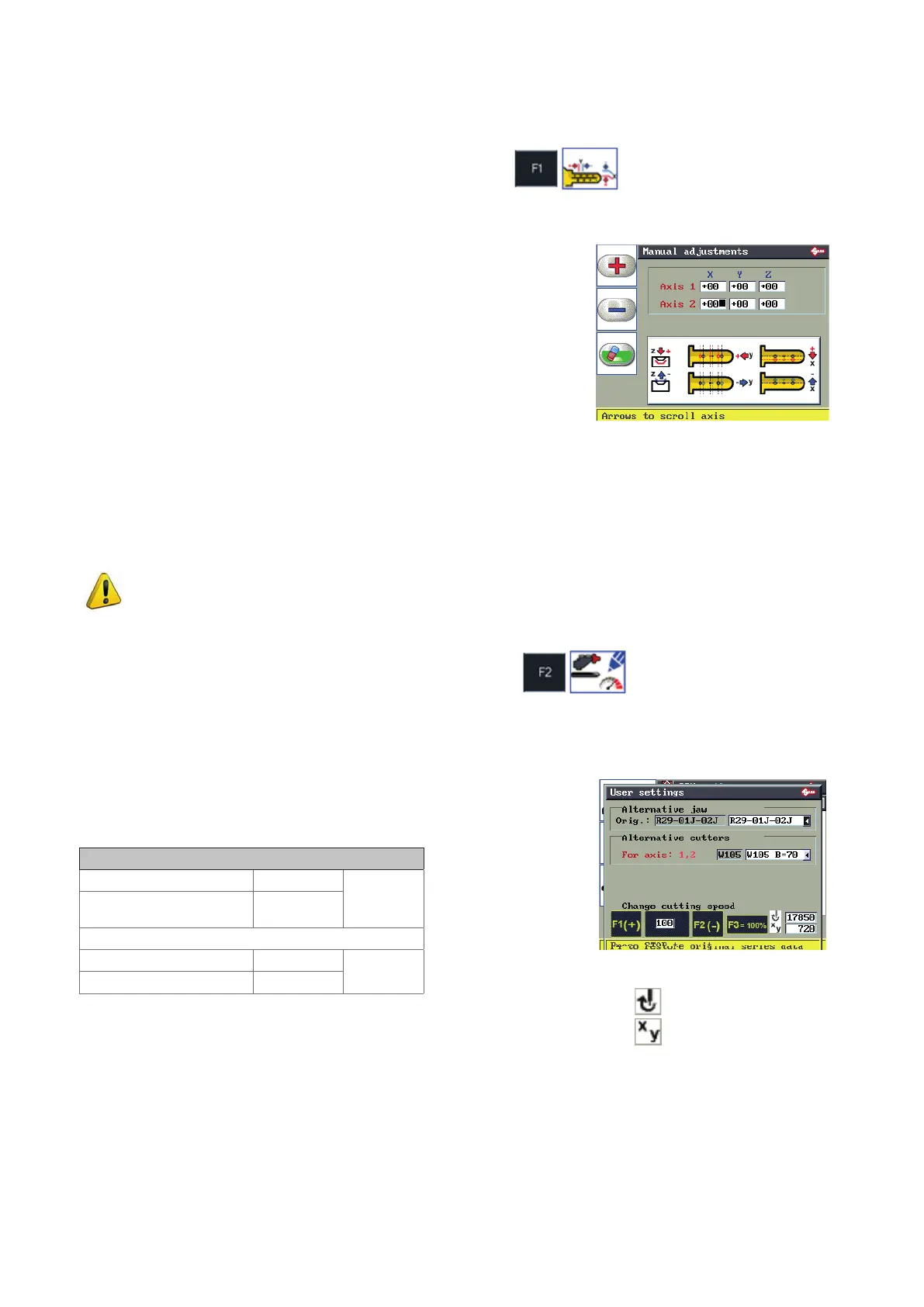

6.5.1 MANUAL ADJUSTMENTS

This function is used to make adjustments to the SSN in use.

• F1 for positive values (+).

• F2 for negative values (-).

• F3 to delete the edited adjustments.

• R/h arrow key to move from eld to eld (X; Y; Z)

• Up-down arrow keys to move from axis to axis (axis 1 - axis 2 - … )

F1

F2

F3

Positive value of X: moves cut to right of axis.

Negative value of X: moves cut to left of axis.

Positive value of Y: takes cut closer to STOP 0.

Negative value of Y: takes cut away from STOP 0.

Positive value of Z: makes cut deeper.

Negative value of Z: makes cut less deep.

Adjustment values for X, Y, Z (-30 to +30 hundredths of mm)..

NOTIFICATION OF VARIATION

This ashing warning symbol appears inside the Manual Adjustment icon only when manual

adjustments have been entered.

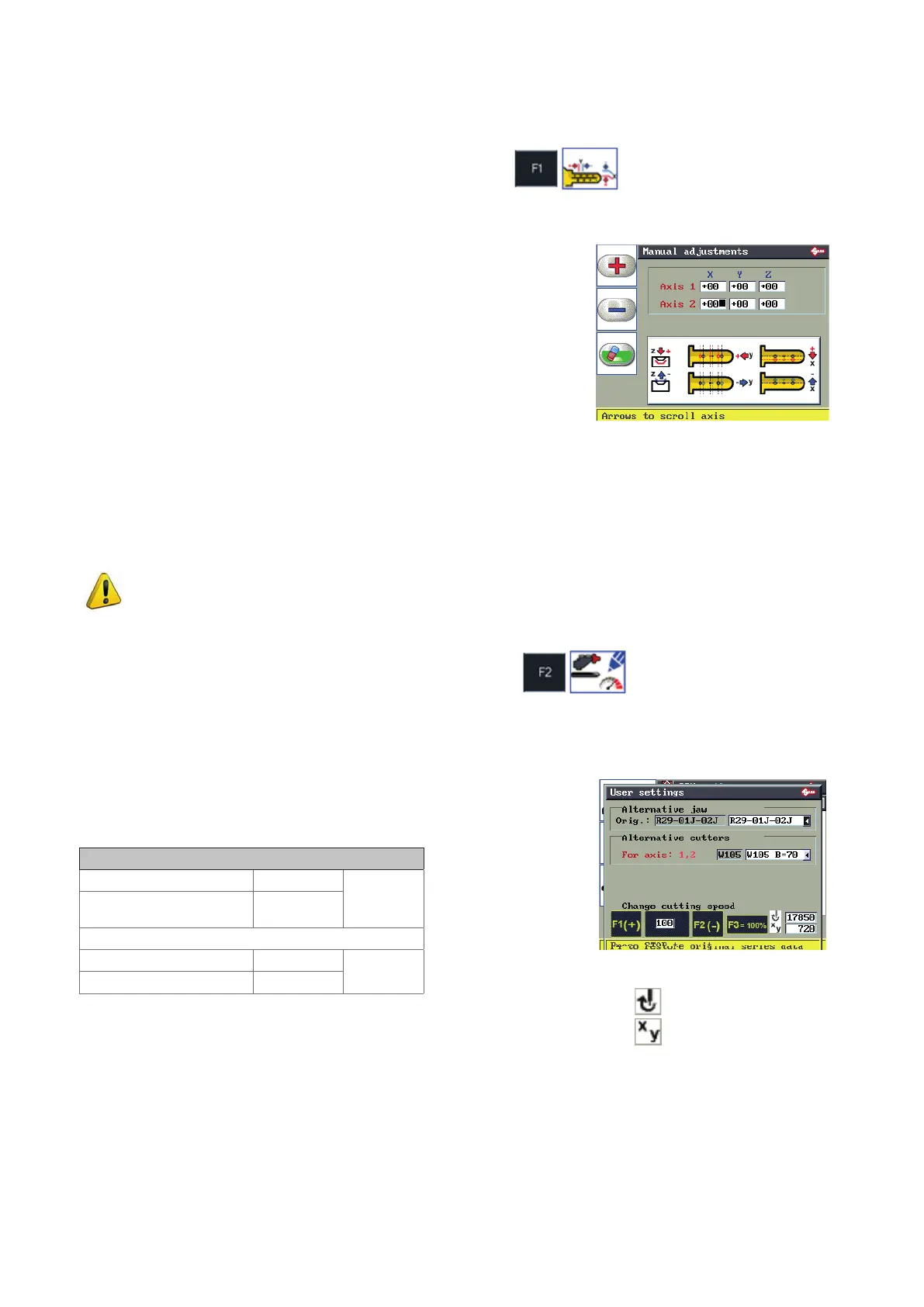

6.5.2 USER PARAMETERS

This function is used to select a clamp or cutter alternative to those provided by Silca. It is also used to vary

working speed (option recommended for OEM users).

Not all Silca Serial Numbers (SSN) will show these parameters.

Change cutting speed

To change cung speed and consequently the number of spindle revs, set

a reducon or increase percentage with keys F1 and F2.

Cutting speed

*Cutting speed 600

+00%

Spindle speed (rpm)

13000

For example, a 10% reduction gives:

540

-10%

14300

(*) variation in the advancing speed of the carriages during the key cutting stage only.

Key F1: to increase the percentage value

Key F2: to decrease the percentage value

Key F3: to reset the Silca default values

Key F4: to reset the User Parameters for clamps and cuers

This funcon assigns a value predened by Silca to all the User Parameters

in the series.

Spindle speed

Carriage movement speed

Note: OEM users see also Ch.6.14.6 OEM MODE [PAGE 5/5].

Operating manual TRIAX PRO

Copyright Silca 2016

37

Loading...

Loading...