6.8.2.1 ENGRAVING DEPTH: METHOD’

METHOD FOR MAKING AN ENGRAVING AT THE RIGHT DEPTH:

A - for material whose thickness can be read by electric contact the cutter stops at the measurement read (by

means of the electric contact function) on the key close to the rst line of text to be engraved, then descends

by a distance given in the set “depth” parameter.

B - for material whose thickness CANNOT be read by electric contact the cutter stops at the measurement

indicated by the “thickness” parameter for the engraving template, then descends by a distance given in the

set “depth” parameter.

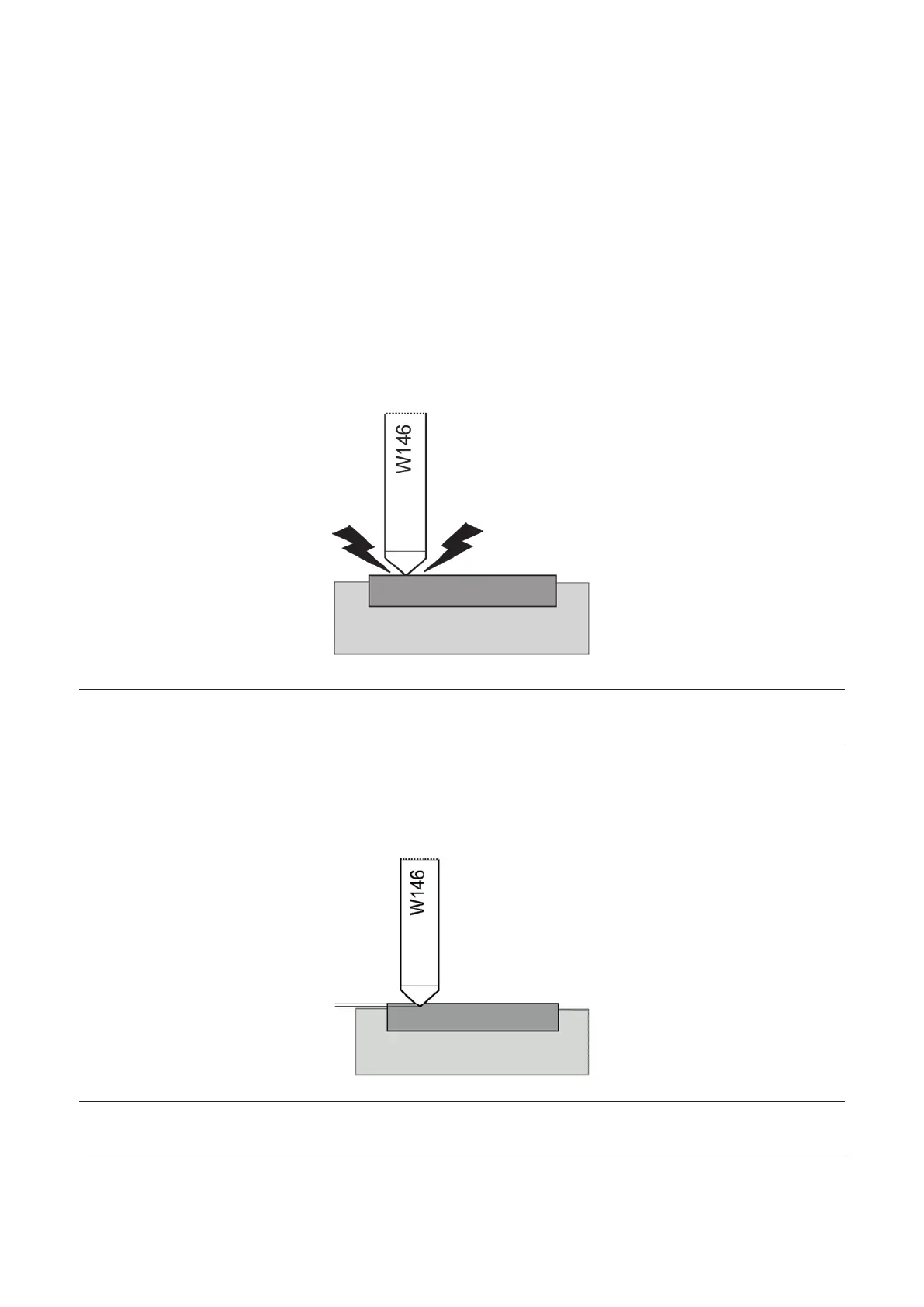

A - ELECTRIC CONTACT POSSIBLE on material to be engraved

NOTE: is better to set the thickness value slightly lower than nominal (read by a centesimal gauge) to assist

reading the measurement by electric contact. Example: if the item to engrave has a thickness of 2.00 mm (200

hundredths of mm) it is better to set a thickness value of 195 hundredths of millimetre.

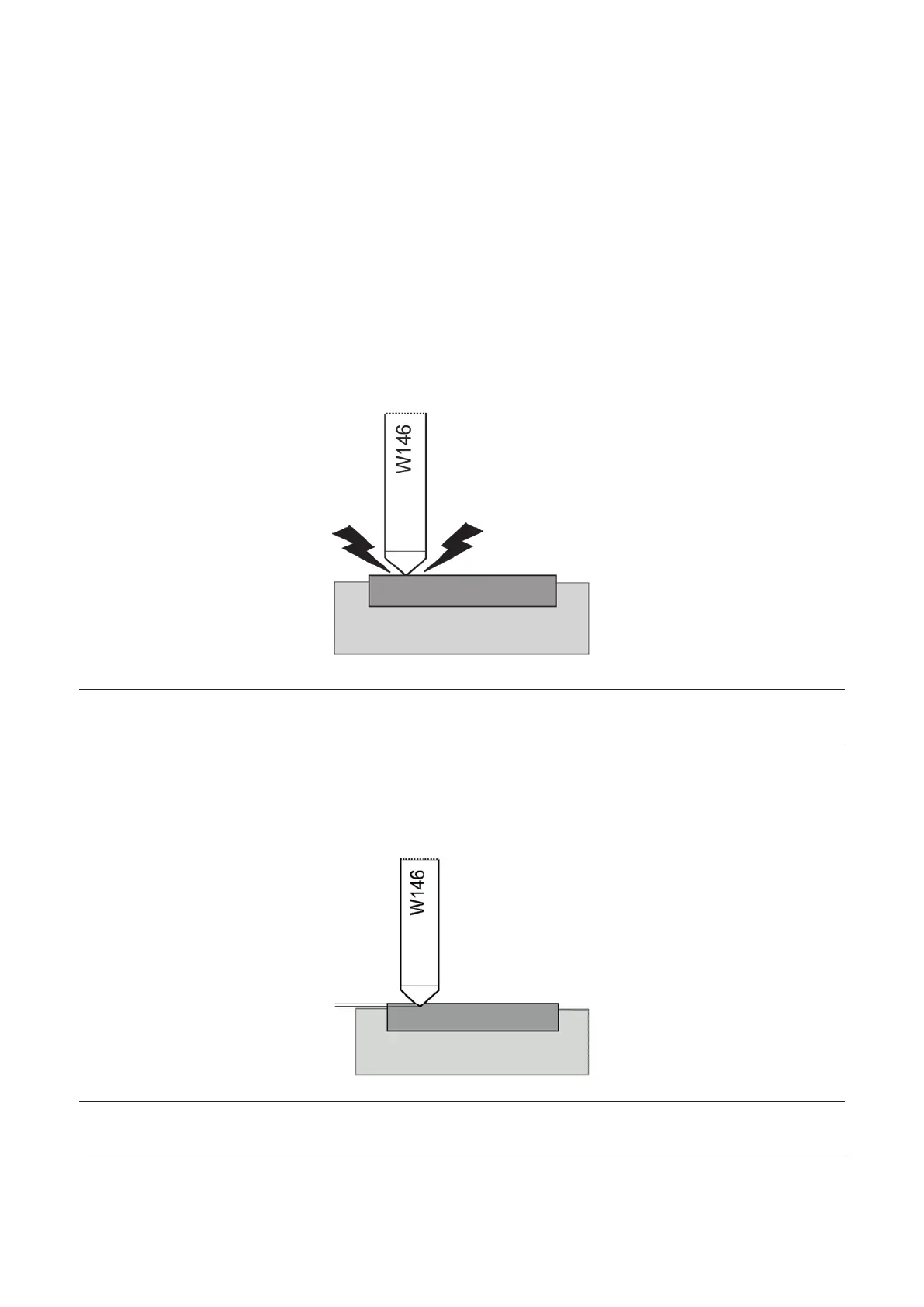

B - NO ELECTRIC CONTACT with the material to be engraved

NOTE: the thickness setting must be as precise as possible to achieve good engraving. Read the thickness of

the item to be engraved with a centesimal gauge and if necessary edit the thickness setting rather than edit the

engraving depth.

Operating manual TRIAX PRO

Copyright Silca 2016

47

Loading...

Loading...