6-3

Routine Maintenance Operator Manual 920011-649

6.3 Debris Screen After last cycle of the day, remove debris screen and clean under

running water. Replace in bottom of chamber. Always clean debris

screen while it is still wet, before debris dries.

6.4 Drip Pan Once a week, remove drip pan and clean under running water.

Replace drip pan in bottom of Bag-in-a-Box compartment.

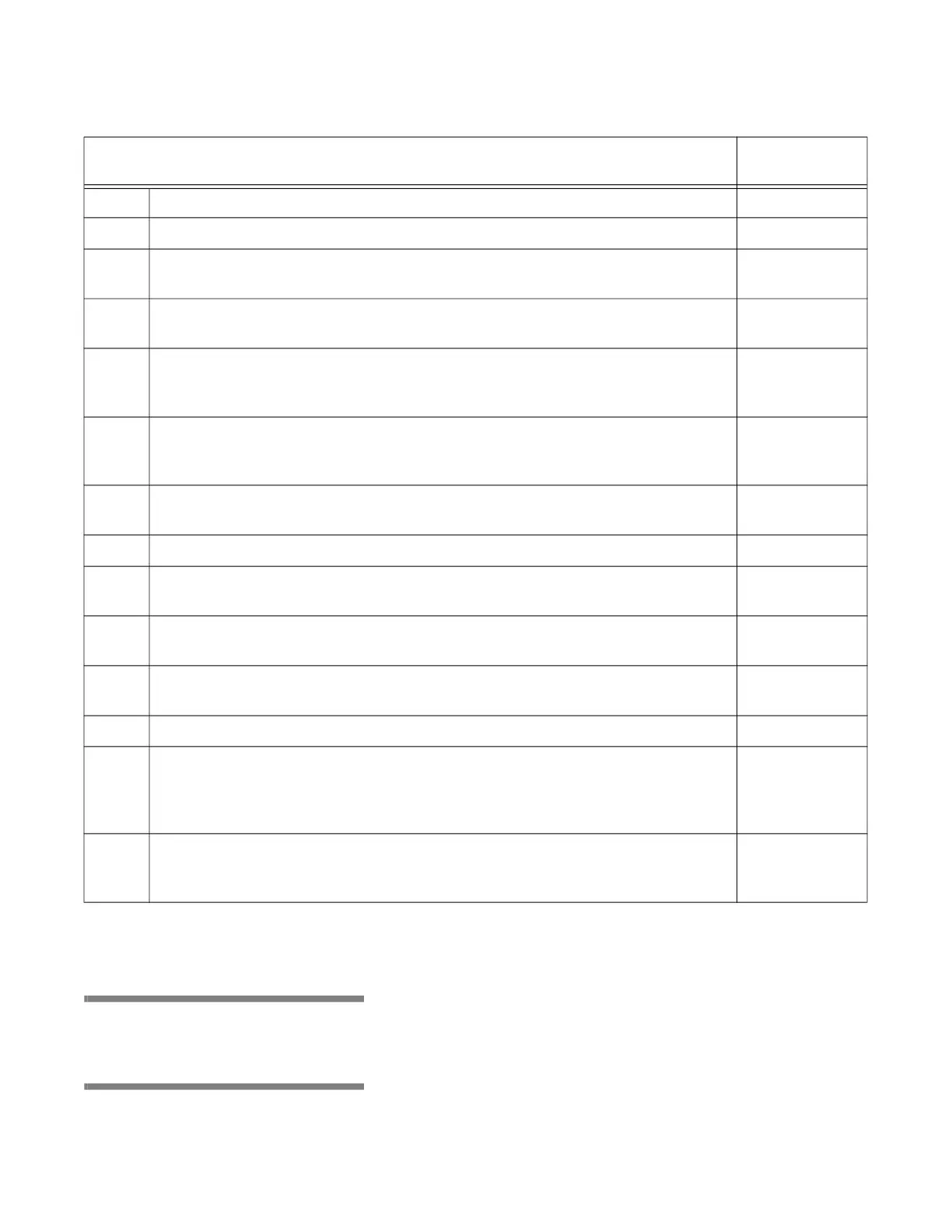

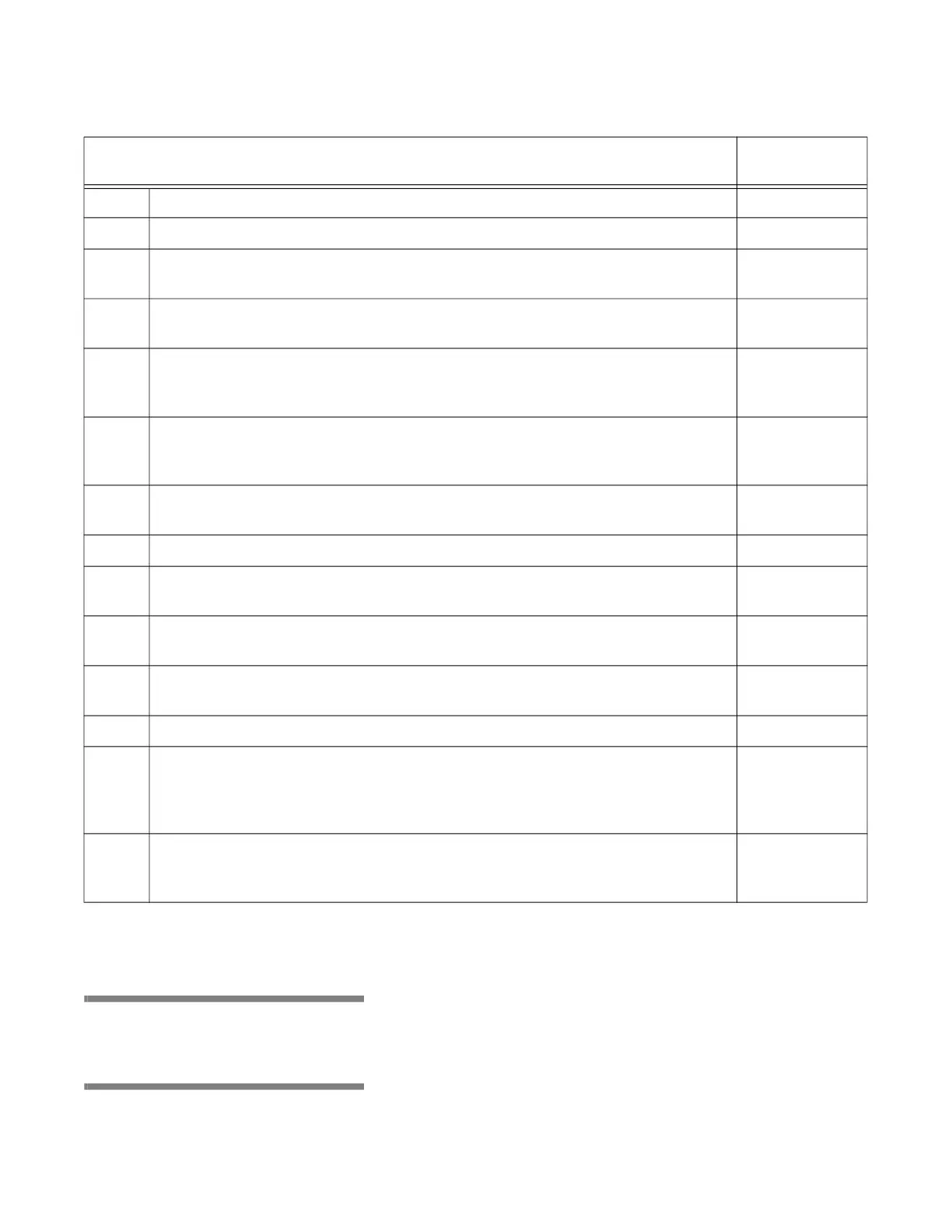

5.0 ENDOSCOPE PROCESSING SUPPORT (Cont’d)

5.5 Verify three punching rods inside the Reliance CDS are tight. If loose, see S

ECTION 6.7. 1 X/week

5.6

Clean holes in valve irrigators and caps using a thin wire (such as a paper clip) or

compressed air.

1 X/week

5.7

Verify light cord sealing flaps on control handle boots are in good condition (not

discolored, cracked or warped). If damaged, call STERIS.*

1 X/week

5.8

Verify flexible silicone tubing of Flow Units is in good condition (not brittle, discolored,

cracked, yellowish). Verify Flow Unit adapters and ports are in good condition. If not,

call STERIS.*

1 X/week

5.9

Verify two control handle boots are in good condition (not discolored, cracked or

warped). Clean sealing surfaces of control handle boots. Verify latches are tight

and working properly. If damaged, call STERIS.*

1 X/week

5.10

Verify pressure transducer hoses (not brittle, discolored, cracked). If damaged,

call STERIS.*

1 X/week

6.0 OPTIONAL AUTOMATED LEAK TEST ASSEMBLY

6.1

Verify hose clamps for loosening or damage. Replace if necessary (refer to

Maintenance Manual [P764333-736] for details).

1 X/year

6.2

Using tool and grease provided in leak test hose assembly maintenance kit

(P117034-898), lubricate O-ring inside leak test hose assembly (see S

ECTION 6.13).

1 X/month

6.3

Replace leak test hose assembly O-ring with new O-ring (provided in leak test

hose assembly maintenance kit [P117034-898]; see S

ECTION 6.14).

As required

7.0 FILTERS

7.1

Verify Dual Pre-Filter and Pressure Regulator Assembly cartridges. Verify filling

time on printout for last ten cycles. An increase of filling time indicates filters are

clogged. Maximum filling time allowed by processor is 3:30 to 5:00 minutes.

Replace filters if necessary (see S

ECTION 6.10.1).

4 X/year

7.2

Replace 0.2 μm bacterial-retentive filter (behind service access panel) every three

months or more frequently when a maintenance due message is displayed (see

S

ECTION 6.10.2).

4 X/year

*Contact STERIS for this service. Service charges may be incurred. Consult your warranty for details.

Table 6-1. Routine Maintenance Guide (Cont’d)

Recommended frequency of inspection is indicated in the right column. Usage and

utility conditions may require more or less frequent inspections.

Suggested

Frequency

Loading...

Loading...