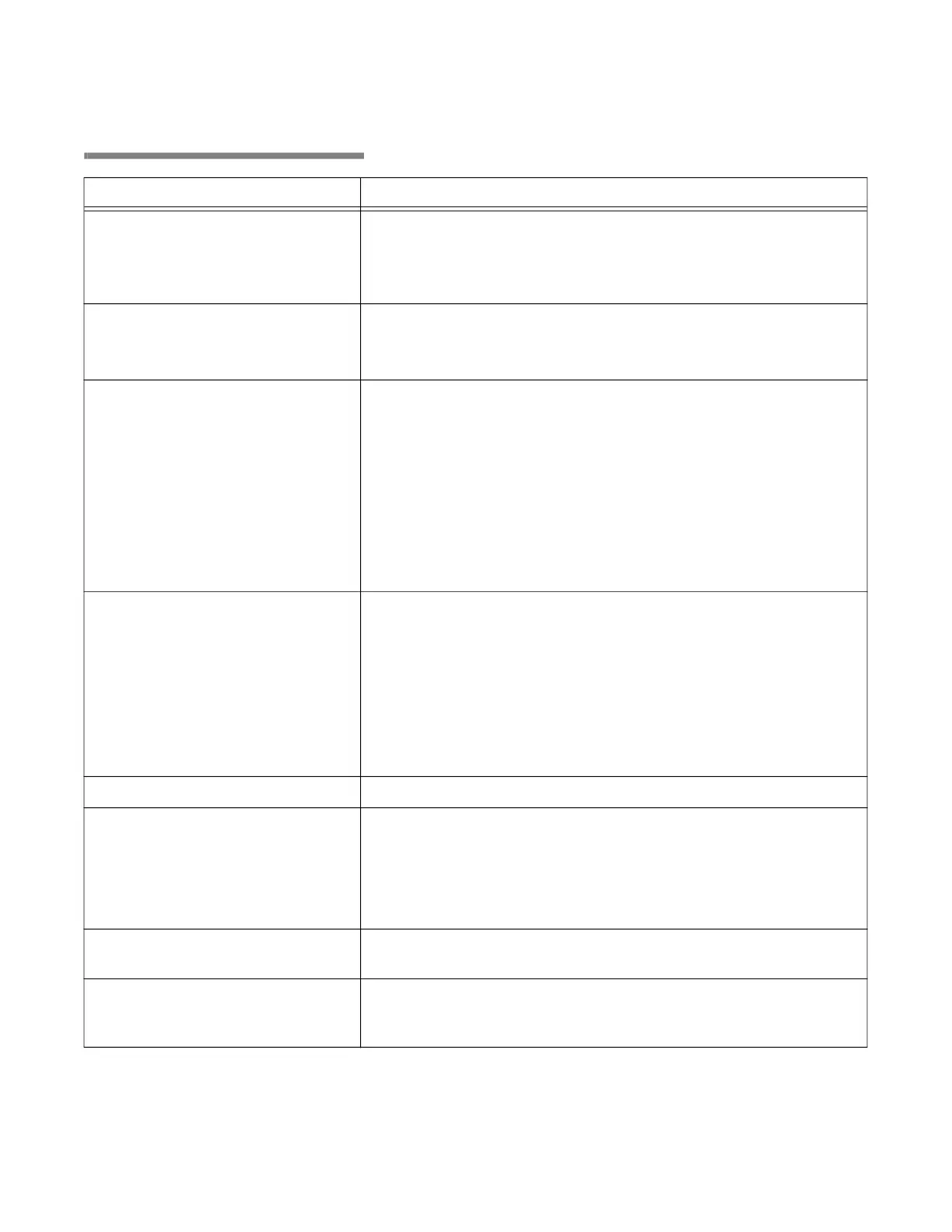

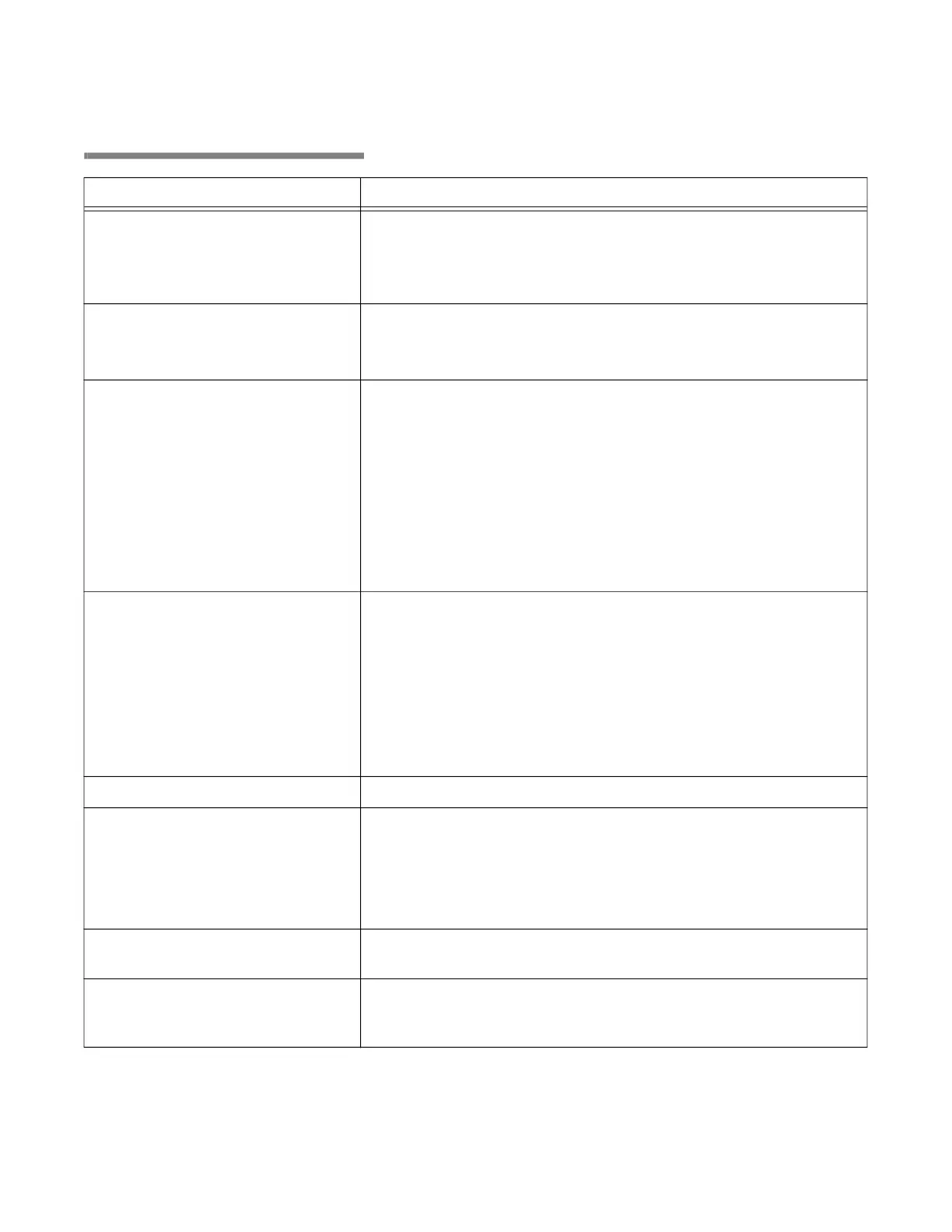

7-2

920011-649 Operator Manual Troubleshooting

7.1 Troubleshooting

Chart

PROBLEM POSSIBLE CAUSE AND CORRECTION

1. Interior light does not turn ON. 1. Unit is in OFF position; press top portion of POWER (ON/OFF)

toggle switch to turn ON processor.

2. Interior light bulb is burned out. Replace light bulb. If faulty, call

STERIS.*

2. Cycle does not start when START

touch pad is pressed.

1. Door is not closed; push door firmly to close and press START

touch pad.

2. If condition reoccurs, call STERIS.*

3. Little or no water through rotary

spray arms or manifolds.

1. Processor rotary spray arms are clogged or obstructed; clean

spray arms (refer to S

ECTION 6.12).

2. Endoscope processing support is not correctly positioned in

chamber. Open door, push support firmly into back of chamber.

3. Chamber debris screen may be clogged; clean if necessary.

4. ENDOSCOPES AND ACCESSORIES MUST BE REPROCESSED

THROUGH A COMPLETE RELIANCE EPS CYCLE (refer to

S

ECTION 4).

5. If condition reoccurs, call STERIS.*

4. Rotary spray arms are not

turning.

1. Bushing not properly installed or missing on rotary spray arm hub

(refer to S

ECTION 6.12).

2. Rotary spray arms are clogged; clean spray arms (refer to

S

ECTION 6.12).

3. ENDOSCOPES AND ACCESSORIES MUST BE REPROCESSED

THROUGH A COMPLETE RELIANCE EPS CYCLE (refer to

S

ECTION 4).

4. If condition reoccurs, call STERIS.*

5. Water leaks from processor. Call STERIS.*

6. Chamber does not drain

completely.

1. Chamber debris screen may be clogged; clean if necessary.

2. ENDOSCOPES AND ACCESSORIES MUST BE REPROCESSED

THROUGH A COMPLETE RELIANCE EPS CYCLE (refer to

S

ECTION 4).

3. If condition reoccurs, call STERIS.*

7. Vapor, mist or unusual odor

emanating from chamber.

Damaged door gasket and/or damaged door interlocks, call STERIS.*

8. Heat loss from chamber. Hot air

escaping from door during air

purge phase.

Damaged door gasket and/or door interlocks, call STERIS.*

*Service charges may be incurred. Consult your warranty for details.

Loading...

Loading...