126

S

3. While wrapping bladder around bearing, place

bladder tting into hole where brake line is

protruding.

4. With brake bladder wrapped around bearing,

place half of the raceway back into position with

bladder housed in raceway.

• Using a small at blade screwdriver, slightly

li the rear M6-40 screw so that the raceway

can t back into its specied location

5. Align threaded holes on raceway with holes

from screws.

Note DO NOT remove the screw from its housing, otherwise retrieval of this screw can

become dicult.

6. Tighten M6-40 screws without stripping head

7. Repeat steps outlined above for the other half of the raceway.

8. Replace upper extension arm access hole plugs (if applicable) by inserting into location.

9. Turn supply brake line gas back on pressurizing boom to 75 ± 5 psi and run through functional-

ity of brakes to ensure no audible leaks can be heard.

10. Replace end cap cover by following steps outlined in 1004-400-061

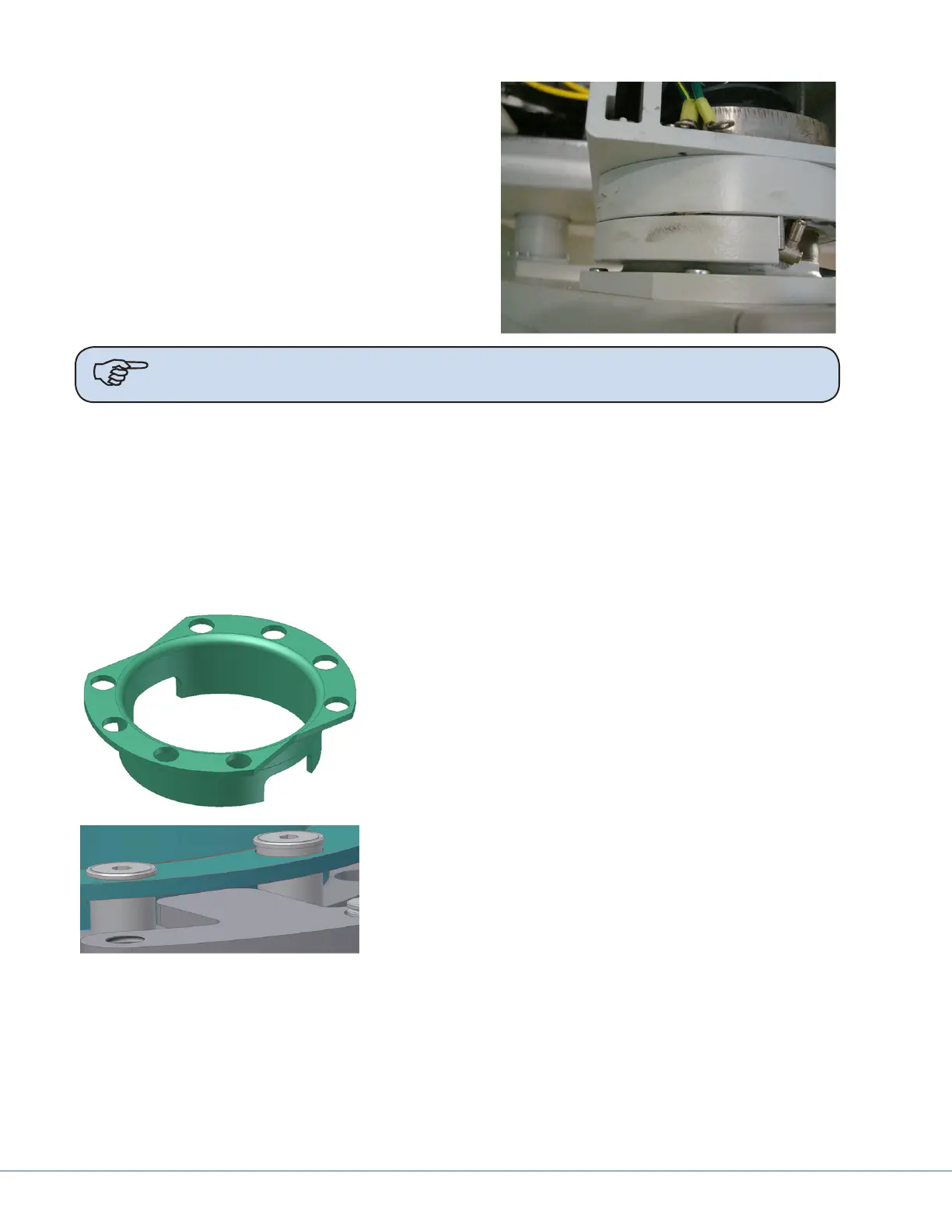

To replace the Protective Collar, do the following:

1. Remove the upper extension arm end cap by following

instructions from 1004-400-061, EDS Installation and

Service Manual.

2. Remove the two M5-25 screws that hold the collar in

place.

3. Back pull cables, conduit, etc. in order to remove the

collar.

4. Install collar into designated location housed within

bearing.

5. Re-install the two M5-25 screws in their designated

location.

6. Pull the cables, conduit, etc. back through the boom.

Loading...

Loading...