20

S

6.2 Surgical Lights

6.2.1 Standard Horizontal Arm

1. Load the suspension shipping box onto a heavy machinery li device.

2. Cut cardboard 9 inches from the top of the box to facilitate hanging suspension. Be careful not

to cut cables or scratch the suspension.

3. Mount down tube onto suspension. Use the six at head socket cap screws (taped to down tube)

to attach the down tube to the central axis spindle. Tighten all screws with a torque wrench set

to 100 lb-in (8.33 lb-, 11.3 Nm). Once all screws have been tightened, retighten each screw to

ensure correct torque is set.

If you are installing a at panel along with a dual light suspension, verify that the at panel cable

kit is routed through the opening in the down tube.

4. Position the suspension assembly directly below the mount site.

5. Go to Section 7, “Installing the Suspension” to complete installation.

6.2.2 Extended Horizontal Arm

1. Remove all accessories and the cardboard box.

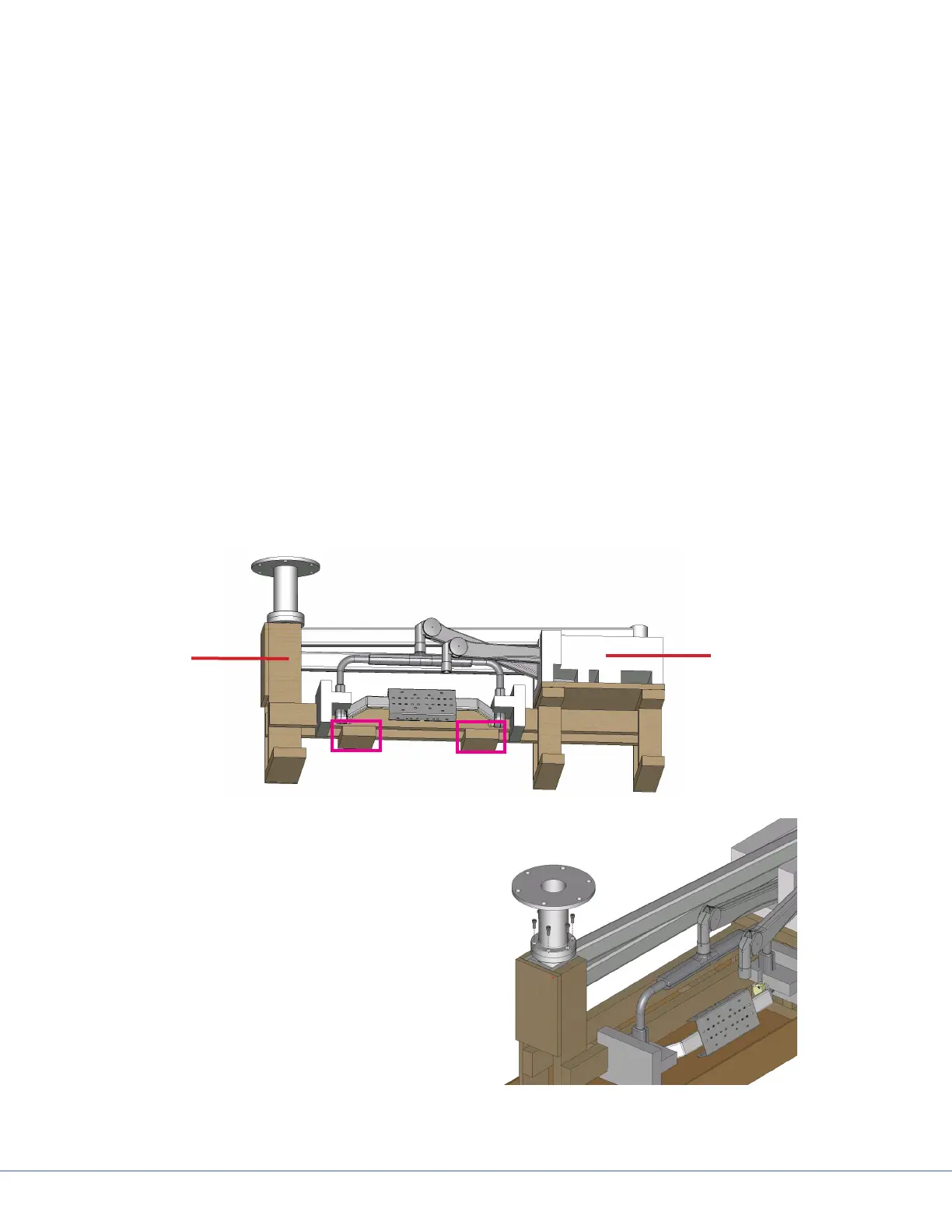

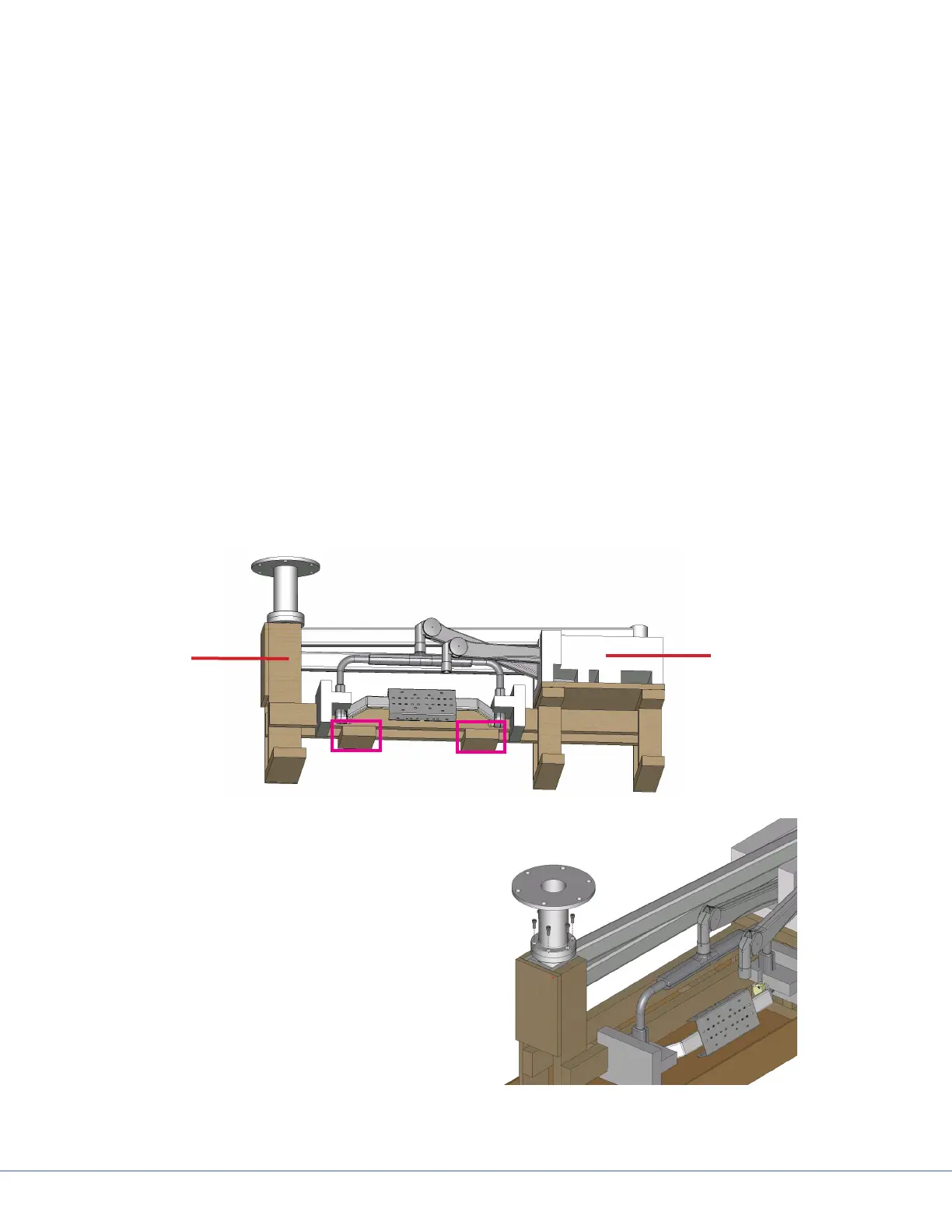

2. Position Genie Life so that forks are underneath the highlighted areas shown in the following

gure.

Brown

packaging is

wood

White

packaging is

styrofoam

3. Mount down tube onto suspension. Use

the six socket cap screws to attach the

down tube to the central axis spindle.

Tighten all screws with a torque wrench

set to 354 lb-in (29.5 lb-, 40 N-m). Once

all screws have been tightened, retighten

each screw to ensure correct torque is set.

If you are installing a at panel along with

a dual light suspension, verify that the at

panel cable kit is routed through the open-

ing in the down tube.

4. Position the suspension assembly directly

below the mount site.

Loading...

Loading...