5-66 4203781 First Edition

HYDROSTATIC POWER TRAIN

5

NOTICE

Inspection Notes

• Keeping parts in assembly order, clean and air dry

each item for inspection.

• Inspect for worn or defective parts.

• Look for metal chips or slivers during cleaning (an

indication of damage to pump or other hydraulic

component).

• Inspect all parts for cracks, nicks, burrs, and

excessive wear. Inspect for scoring, galling, and

scratches on surfaces. Replace parts as necessary.

Assembly Notes

NOTICE

• Assemble the rear wheel motor by reversing the

order of disassembly.

• Lubricate all O-rings prior to assembly.

• Time the motor correctly. (See “Rear Wheel Motor

Timing” on page 5-67.)

• Tighten valve housing screws (19) to 36–37 lb-ft

(49–50 N·m).

• Pressure filter traction system upon start-up if metal

debris is found in system oil or motor. (See “Portable

In-Line Filter” on page 5-4.)

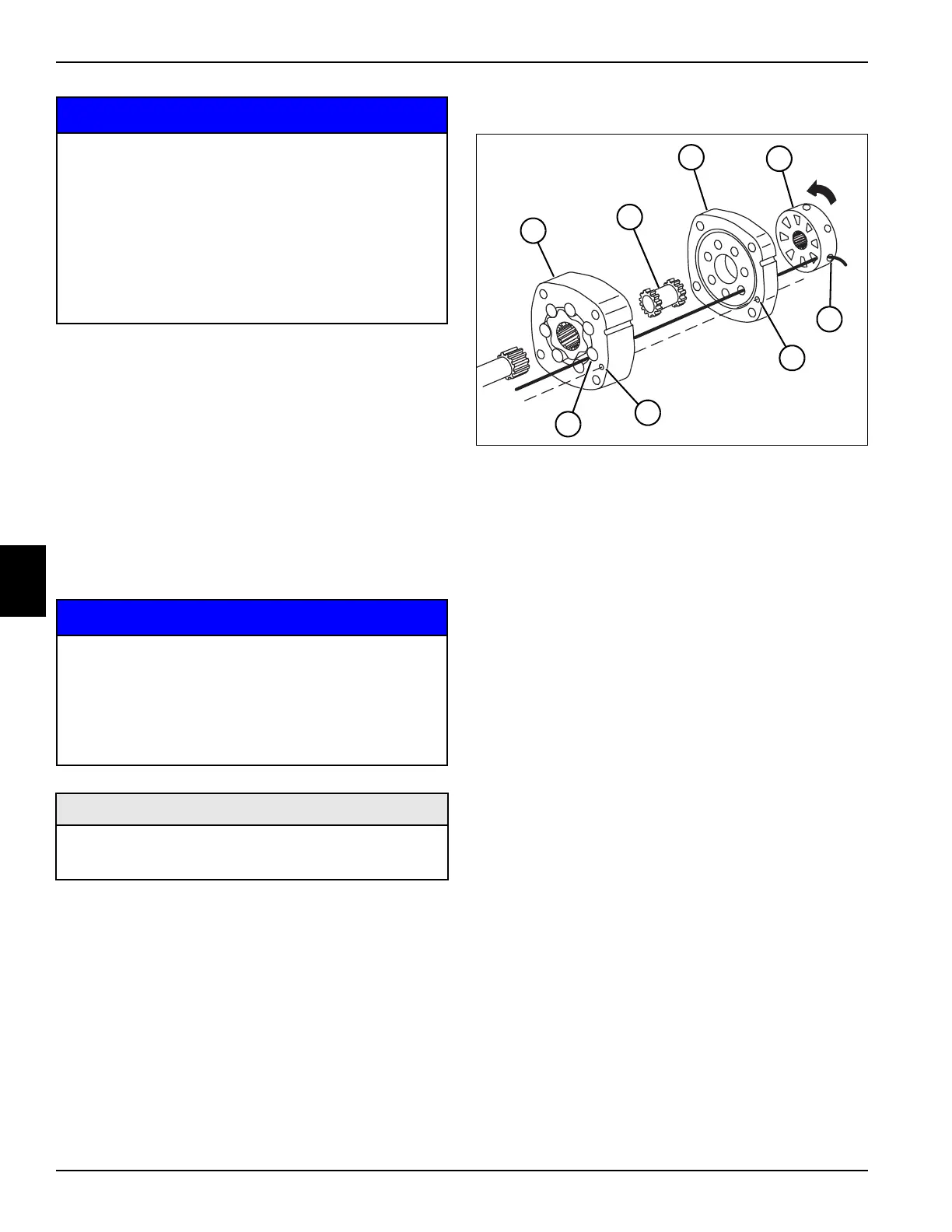

Rear Wheel Motor Timing

Figure 5-63: Correct Motor Timing

1. Locate the largest open pocket (8) in geroler (1).

Mark the location of the pocket on the outside edge

of geroler.

2. Align the case drain hole (7) in the geroler with the

case drain hole in the bearing housing. Install the

geroler on the bearing housing. Retain the rollers in

the outer geroler ring if they are loose.

3. Install the valve drive (2) in geroler (1).

4. Lubricate the seal and install it in the valve plate (3).

5. Align the case drain hole (6) in the valve plate (3)

with the case drain hole (7) in the geroler (1). Install

the valve plate (3) with the seal side toward the

geroler.

6. Locate the slot in the valve plate (3) that is in line with

the largest open pocket (8) of geroler.

7. Locate any side valve opening (5) through to the face

of the valve. Line up the opening with the open slot of

the valve plate that is in line with the largest open

pocket of geroler. Rotate valve (4) clockwise 1/2

spline tooth to engage with the valve drive.

• It is important that motor parts are marked

and placed in assembly order to aid in

assembly.

• It is important that all motor parts are

absolutely clean, as contamination can result

in serious damage and/or improper operation.

• Never use shop towels or rags to dry parts

after cleaning, as lint may clog passages. Dry

parts using compressed air.

• It is important that all component parts are

absolutely clean, as contamination can result

in serious damage and/or improper operation.

• Never use shop towels or rags to dry parts

after cleaning, as lint may clog passages. Dry

parts using compressed air.

Required Materials

• Seal Kit (Jacobsen PN 5003385)

• Shaft and Bearing Kit (Jacobsen PN 5003384)

TN1541

8

7

5

4

3

6

1

2

Loading...

Loading...