HYDRAULICS

673831-Rev A 6-51

6

Disassembly, Inspection, and Assembly

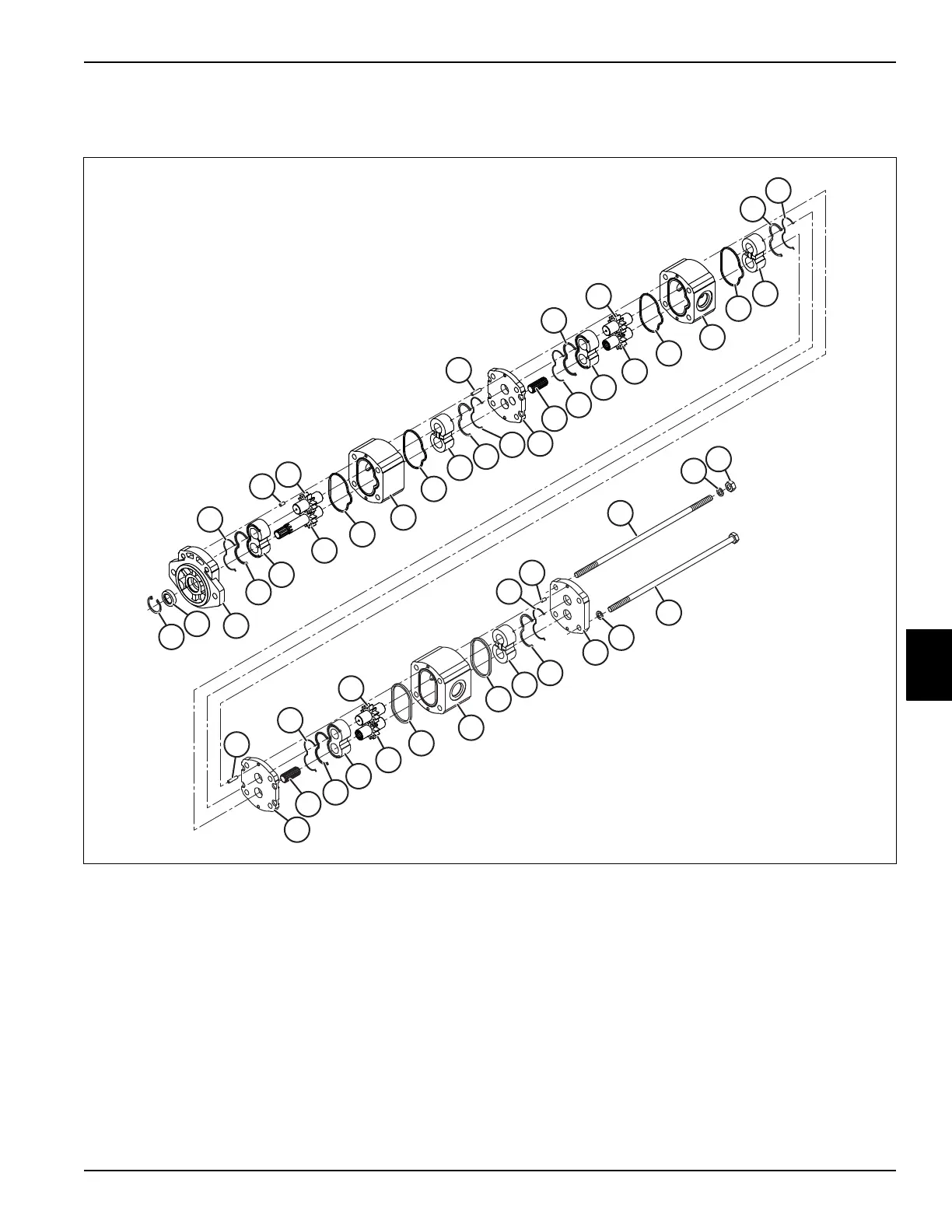

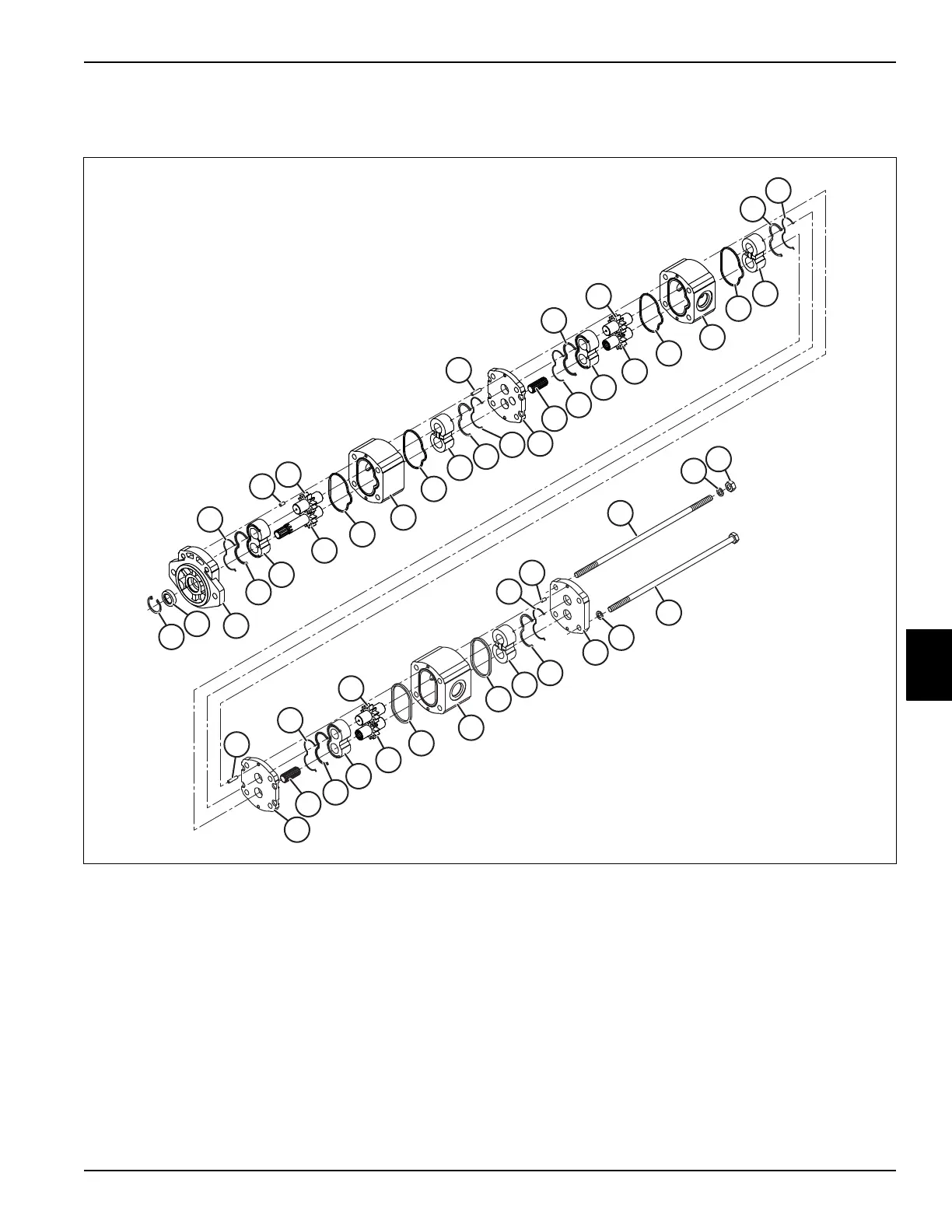

See Figures 6-54 and 6-55.

Figure 6-54

Disassembly Notes

• Do not disassemble pump for repair unless test

procedures indicate internal leakage.

• Never pry components apart. Use a soft face

hammer, and gently tap housing and shaft to

separate pump bodies.

• Scribe or mark the pump bodies and end covers

before disassembly to aid in assembly.

Recommended method of marking body sections is

to use a fine point metal punch, making one

indentation for section #1, two indentations for

section #2, etc.

1 Section 1, 0.403 in

3

Body 7 0.403 in

3

Drive Gear (2) 13 Section Seal (2) 19 Flange (Section 2-3)

2 Section 2, 0.403 in

3

Body 8 0.403 in

3

Input Shaft 14 Section Seal (4) 20 38 mm Drive Hub

3 Section 3, 0.403 in

3

Body 9 0.403 in

3

Driven Gear (3) 15 Shaft Seal 21 10 mm Dowel Pin (4)

4 Front Flange 10 Screw (4) 16 Retaining Ring 22 22 mm Dowel Pin (4)

5 Rear Flange 11 Washer (4) 17 Anti-Extrusion (6)

6 Thrust Plate (6) 12 Thrust Plate Seal (6) 18 Flange (Section 1-2)

1

2

3

4

5

6

6

6

6

6

6

7

7

8

9

9

9

10

11

12

13

13

14

14

14

14

14

14

15

16

15

16

16

16

17

18

19

19

19

19

19

19

20

21

22

22

23

24

23

24

Loading...

Loading...