Fuel System (Fuel Injection)

4-22

4st 25/30 2022

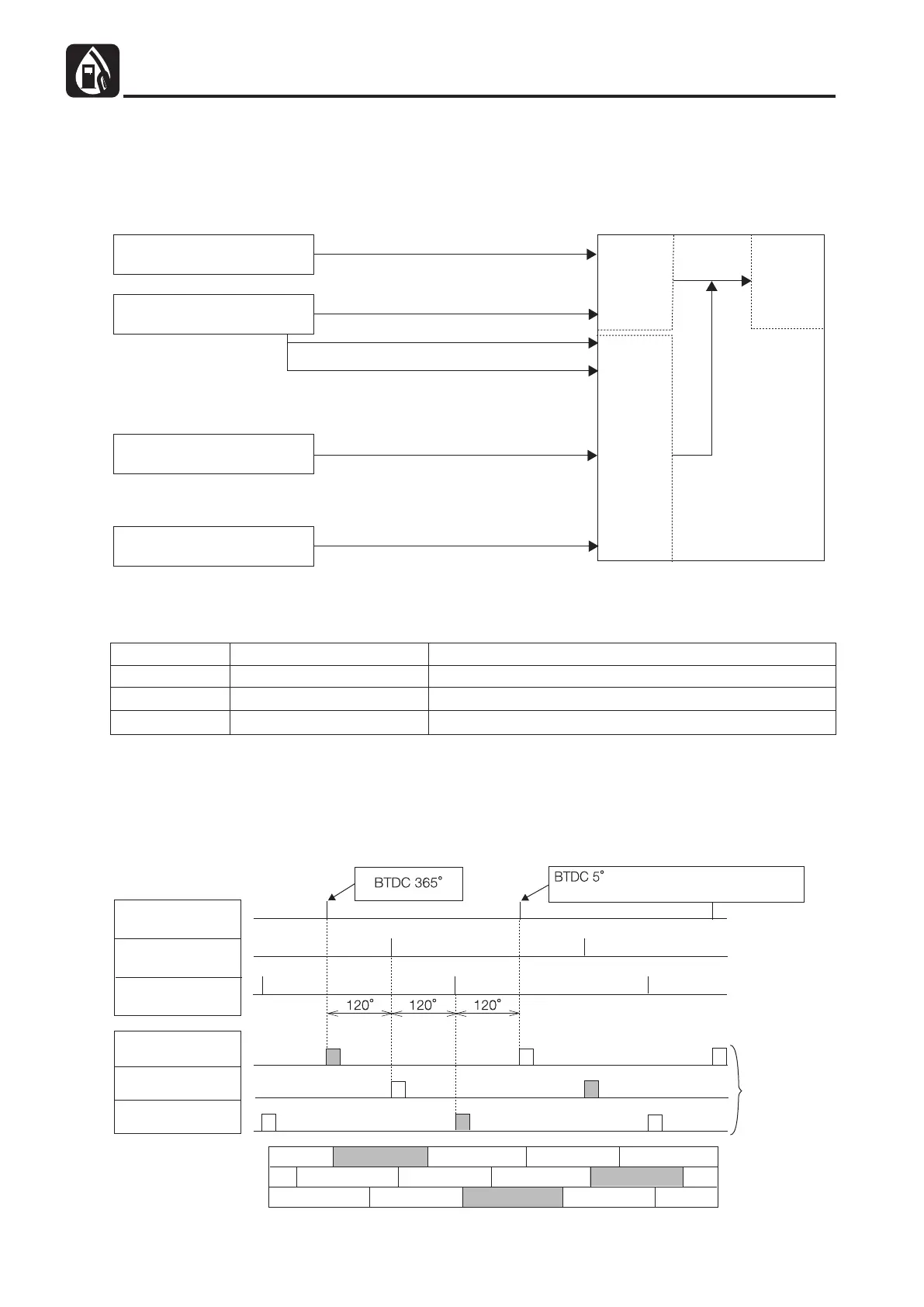

(3) Fuel Injection Control

The ECU calculates the intake air quantity based on the engine revolution speed and intake manifold pressure

(intake vacuum pressure) to determine the fuel injection amount.

During engine startup, warm-up, acceleration/deceleration, and idling, the ECU performs correction control based on

information from the sensors.

Pulser Coil

T-MAP (Manifold Pressure,

Manifold Temperature) Sensor

Engine Temperature Sensor

TPS (Throttle Position) Sensor

Engine Revolution Speed and Crank Angle

Manifold Pressure (Intake Vacuum Pressure)

Atmospheric Pressure at Starting

Manifold Intake Air Temperature

Change of Pressure (Vacuum Pressure)

at Acceleration/Deceleration

Cylinder Cooling Water Temperature

Injection

Amount

Correction

Basic

Injection

Amount

ECU

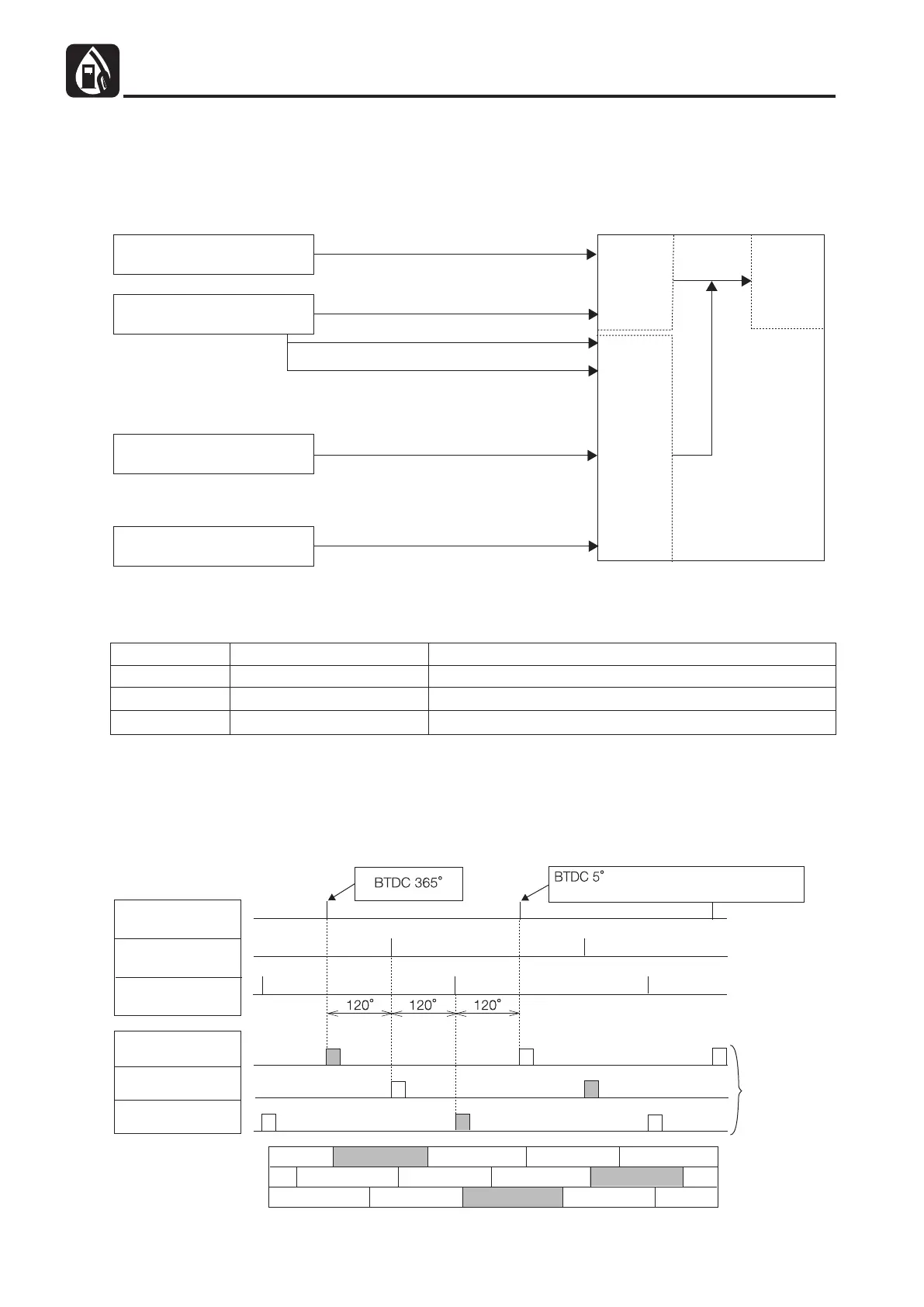

1) Fuel Injection Timing

Fuel injection timing at starting and during normal operation are described in the following table.

Cylinder No.

1

2

3

Reference Signal

#1 Crank Angle Signal

#2 Crank Angle Signal

#3 Crank Angle Signal

Injection Timing (with reference to individual cylinders)

BTDC 365° and BTDC 5°

BTDC 365° and BTDC 5°

BTDC 365° and BTDC 5°

Remarks: 1) No. of fuel injections : Once per revolution of each cylinder (around the end of the compression and

exhaust strokes)

2) Injection sequence : #1 ¤ #2 ¤ #3 ¤ #1 ¤ #2 ¤ #3 ¤ #1 (for every 120° of the crank angle)

3) Combustion sequence : #1 ¤ #3 ¤ #2 ¤ #1 (for every 240° of the crank angle)

4) Injection timing diagram is shown below.

Crank Angle Signal

of No. 1 Cylinder

Crank Angle Signal

of No. 2 Cylinder

Crank Angle Signal

of No. 3 Cylinder

Injector of No. 1

Cylinder

Injector of No. 2

Cylinder

Injector of No. 3

Cylinder

Strokes of No. 1 Cylinder

Strokes of No. 2 Cylinder

Strokes of No. 3 Cylinder

(with reference to No. 1 cylinder

compression stroke top dead center)

Exhaust

Injection

Timing

CombustionCompressionIntakeExhaust

ExhaustCombustionCompression Intake

Compression

ExhaustCombustion Intake Compression Combustion

Injection Timing Diagram

Loading...

Loading...