3-12

Maintenance

4st 25/30 2022

4. If the specified pressure cannot be maintained, check

the oil seals of the drive shaft and propeller shaft and the

O-ring of the shift shaft for any damage.

3. Apply the specified pressure to the gear case, and check if

the pressure can be held for 10 seconds.

Do not subject the gear case to a pressure

over the specified value.

Doing so can cause damage to the oil seal.

Specified Gear Case Holding Pressure:

0.05 MPa (7 psi) [0.5 kgf/cm

2

]

10)

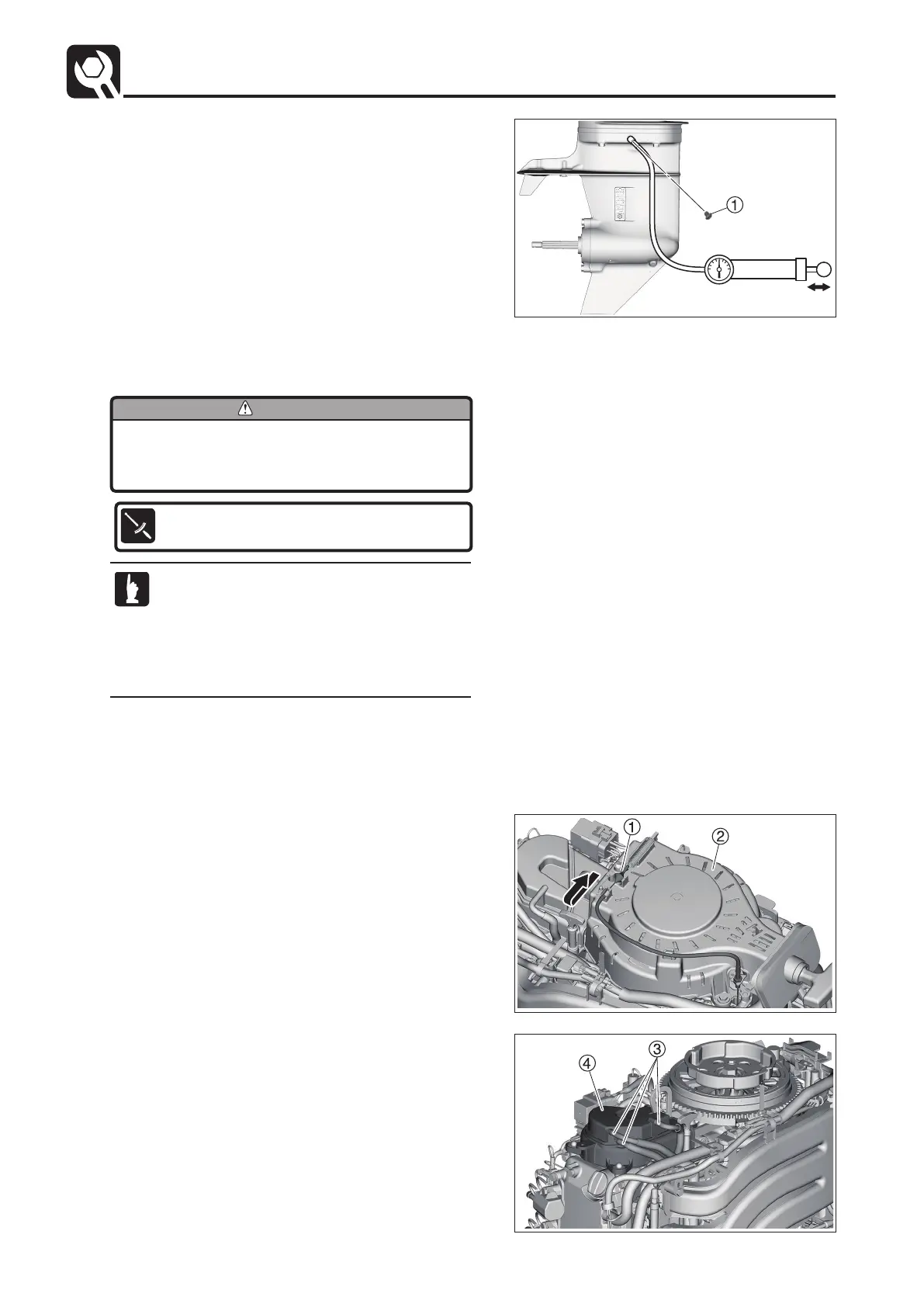

Inspection of Gear Case (for leakage)

1. Drain the gear oil.

2.

Remove the upper oil plug

1

and connect a commercially

available leakage tester to the hole.

•

When the propeller shaft is rotated while

maintaining the pressure, it is easier to locate

air leaks due to the oil seal lip being worn out.

•

Depressurize the gear case and cover the

oil plug area with a piece of rag before

disconnecting the leakage tester.

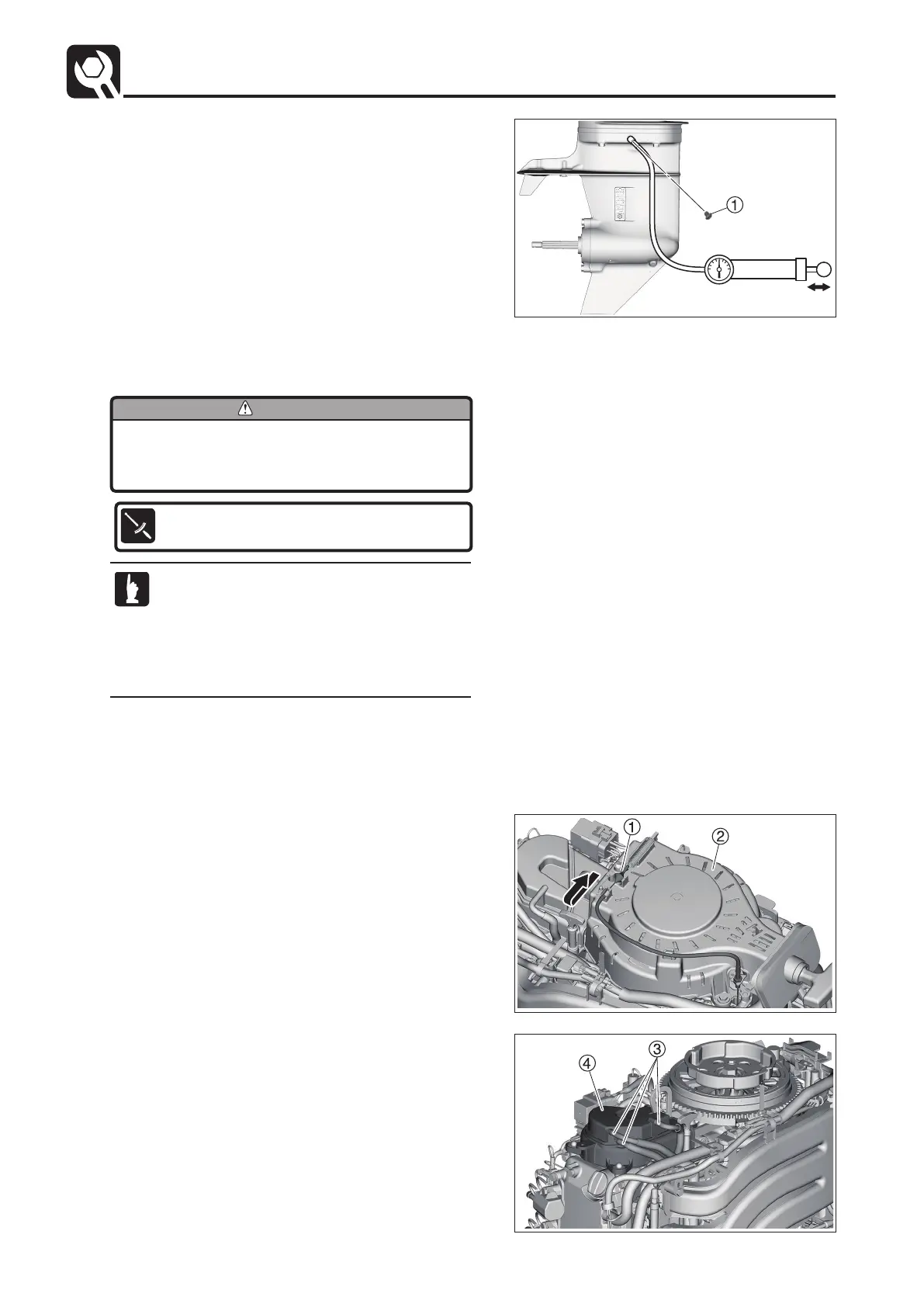

11) Inspection of Timing Belt

1. Remove the

starter lock cable 1 and recoil starter 2 (3

bolts).

2. Disconnect the

vent hose 3 and remove the belt cover 4.

Loading...

Loading...