P3.13.6.5 RESPONSE TO PID SUPERVISION FAULT (ID 749)

Use this parameter to select the response of the drive to a 'PID Supervision' fault.

If the PID feedback value is not in the supervision limits for longer than the supervision delay,

a PID supervision fault occurs.

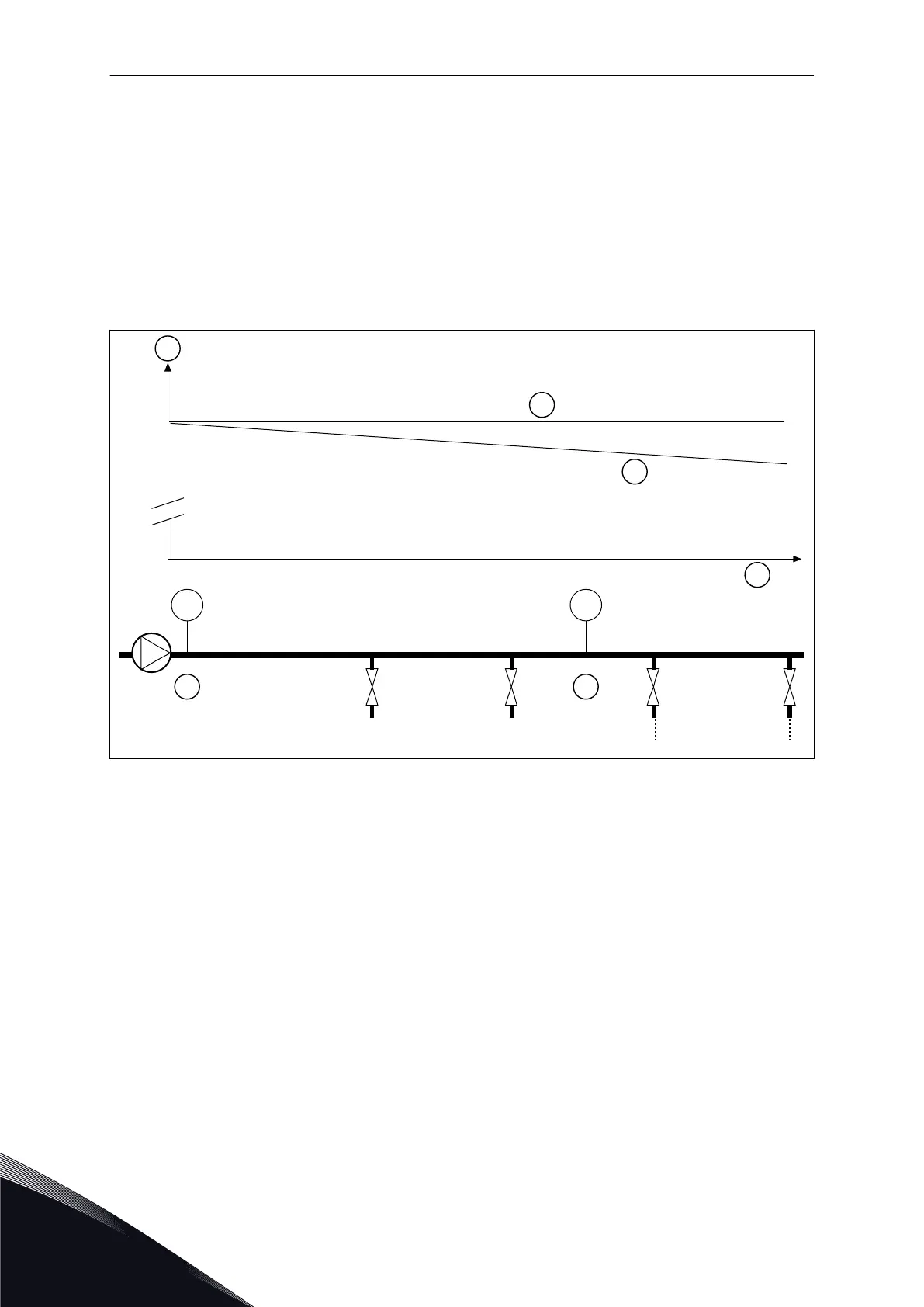

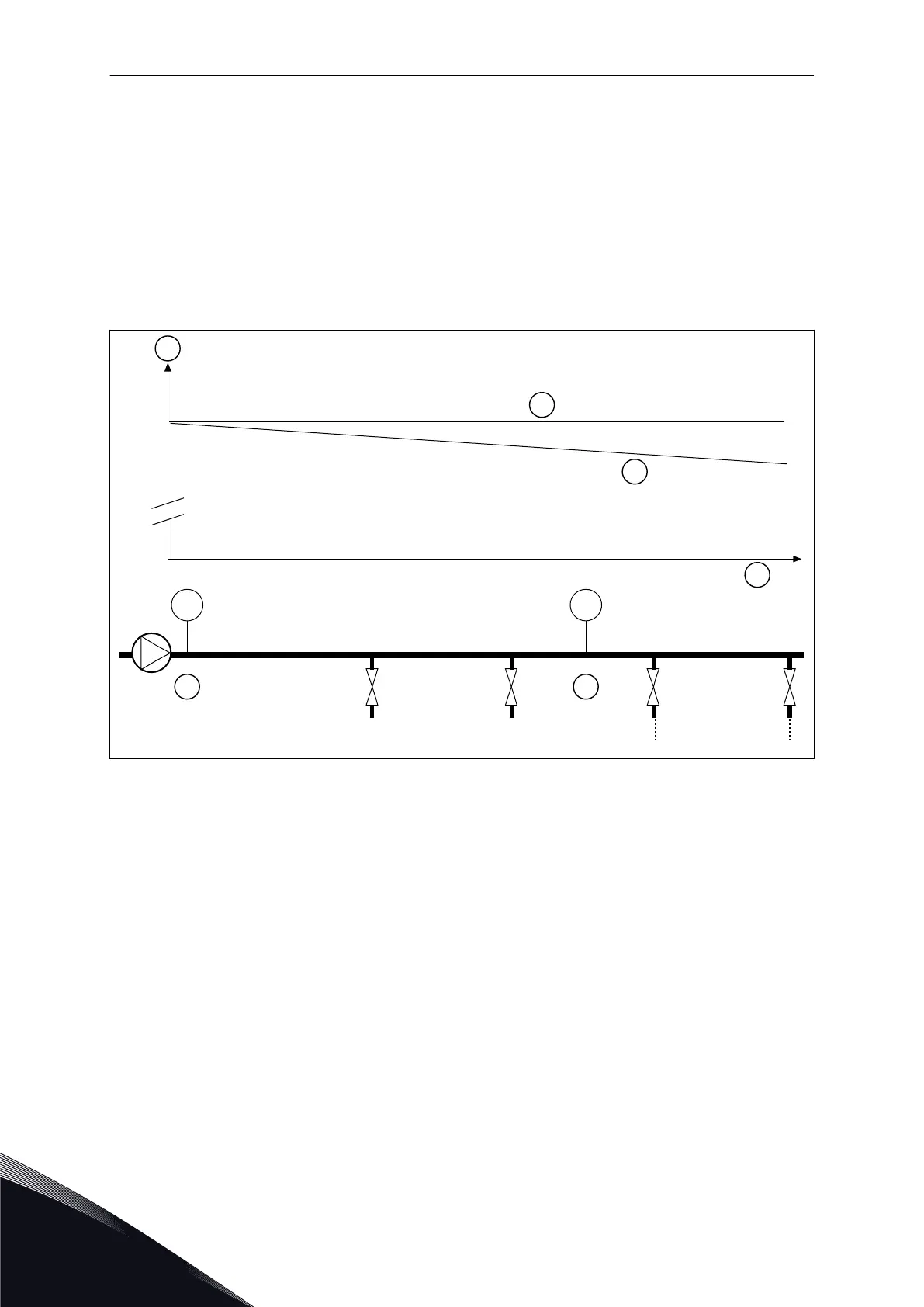

10.14.7 PRESSURE LOSS COMPENSATION

When you pressurise a long pipe that has many outlets, the best position for the sensor is in

the middle of the pipe (the position 2 in the figure). You can also put the sensor directly after

the pump. This gives the right pressure directly after the pump, but farther in the pipe, the

pressure drops with the flow.

Fig. 85: The position of the pressure sensor

A. Pressure

B. No flow

C. With flow

D. Pipe length

E. Position 1

F. Position 2

P3.13.7.1 ENABLE SETPOINT 1 (ID 1189)

Use this parameter to enable the pressure loss compensation in the pump system.

In a pressure controlled system, this function compensates the pressure loss that occurs at

the end of the pipe line due to the liquid flow.

P3.13.7.2 SETPOINT 1 MAX COMPENSATION (ID 1190)

Use this parameter to set the maximum compensation for PID setpoint value that is applied

when the output frequency of the drive is at the maximum frequency.

The compensation value is added to the actual setpoint value as a function of the output

frequency.

Setpoint compensation = max compensation * (FreqOut-MinFreq)/(MaxFreq-MinFreq).

VACON · 312 PARAMETER DESCRIPTIONS

10

LOCAL CONTACTS: HTTP://DRIVES.DANFOSS.COM/DANFOSS-DRIVES/LOCAL-CONTACTS/

Loading...

Loading...