P3.15.22.2 DE-STAGING FREQUENCY (ID 15546)

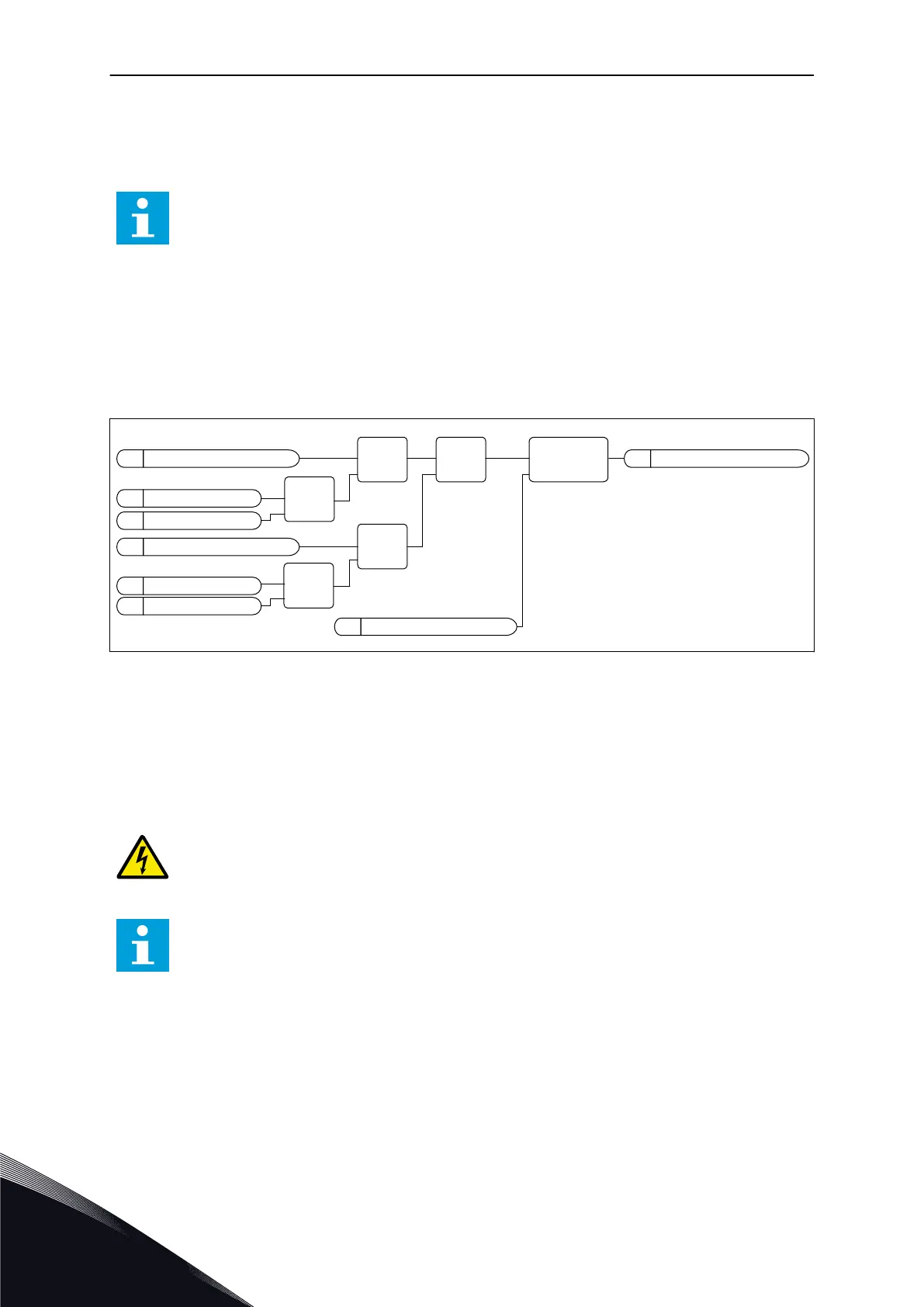

Use this parameter to adjust the output frequency level at which the auxiliary motor stops in

the Multi-pump system.

NOTE!

The parameter has no effect, if its value is set below Min Frequency Reference

(P3.3.1.1).

By default, an auxiliary pump stops (is de-staged), if the PID feedback signal goes above the

specified bandwidth area and the pump that controls the system operates at the minimum

frequency.

The auxiliary pump can stop at a higher frequency to get better process values or to use less

energy. Then, use the parameter to set the start frequency of the auxiliary pump above the

minimum frequency.

M

PID Feedback

P

Banwidth Delay

Stop Aux Pump

V

M

Output Freq

M

PID Setpoint

P

Freq Ref Min

P

De-Staging Freq

P

Bandwidth

GT

IN1

IN2

LT

IN1

IN2

MAX

IN1

IN2

ADD

IN1

IN2

AND

IN1

IN2

ON-DELAY

IN OUT

TIME

Fig. 103: De-staging frequency

10.17 MAINTENANCE COUNTERS

A maintenance counter tells you that maintenance must be done. For example, it is

necessary to replace a belt or to replace the oil in a gearbox. There are 2 different modes for

the maintenance counters, hours or revolutions*1000. The value of the counters increases

only during the RUN status of the drive.

WARNING!

Do not do maintenance if you are not approved to do it. Only an approved electrician

can do maintenance. There is a risk of injury.

NOTE!

The revolutions mode uses motor speed, which is only an estimate. The drive

measures the speed every second.

When the value of a counter is more than its limit, an alarm or a fault shows. You can

connect the alarm and fault signals to a digital output or a relay output.

When the maintenance is completed, reset the counter with a digital input or parameter

P3.16.4 Counter 1 Reset.

VACON · 342 PARAMETER DESCRIPTIONS

10

LOCAL CONTACTS: HTTP://DRIVES.DANFOSS.COM/DANFOSS-DRIVES/LOCAL-CONTACTS/

Loading...

Loading...