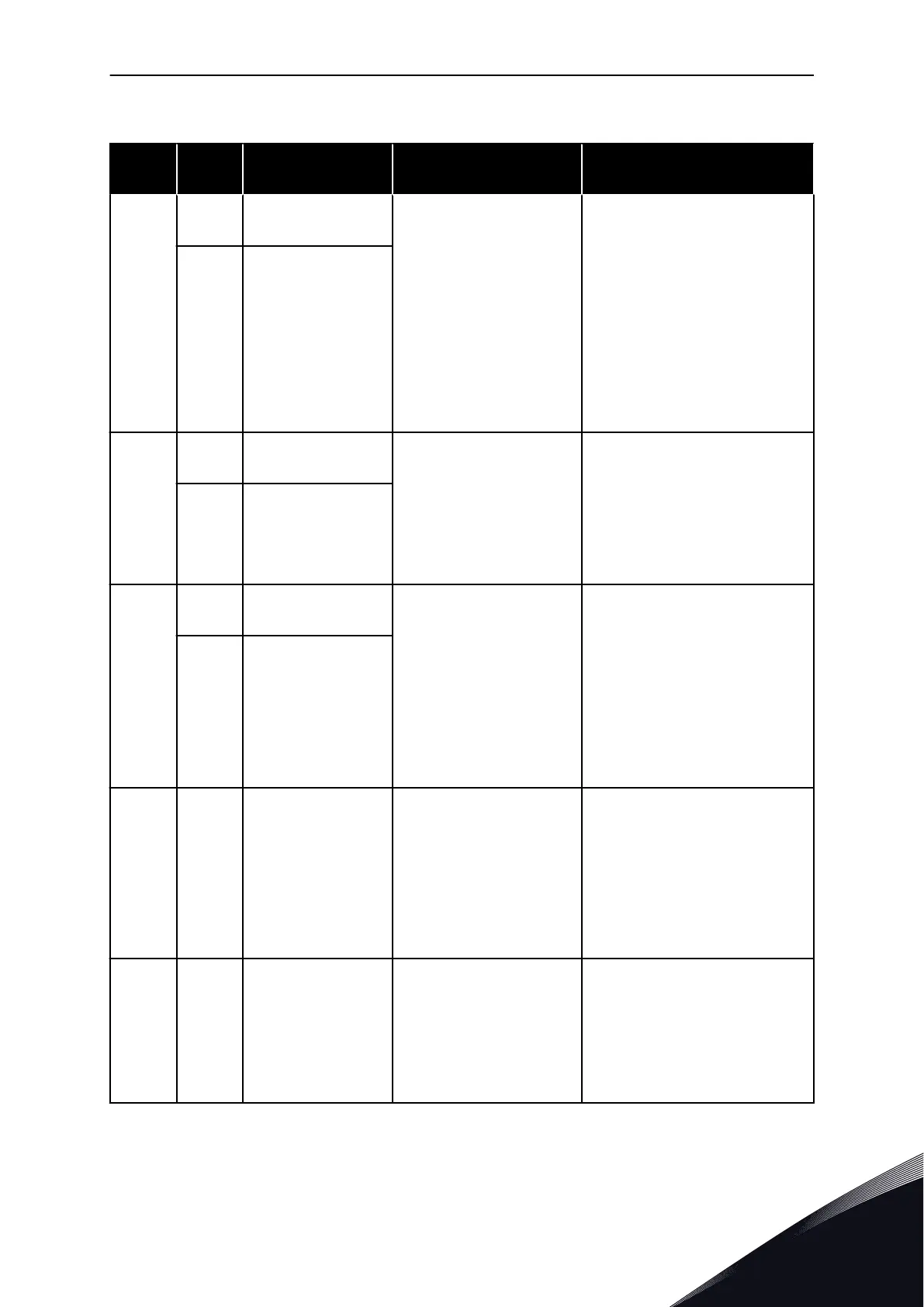

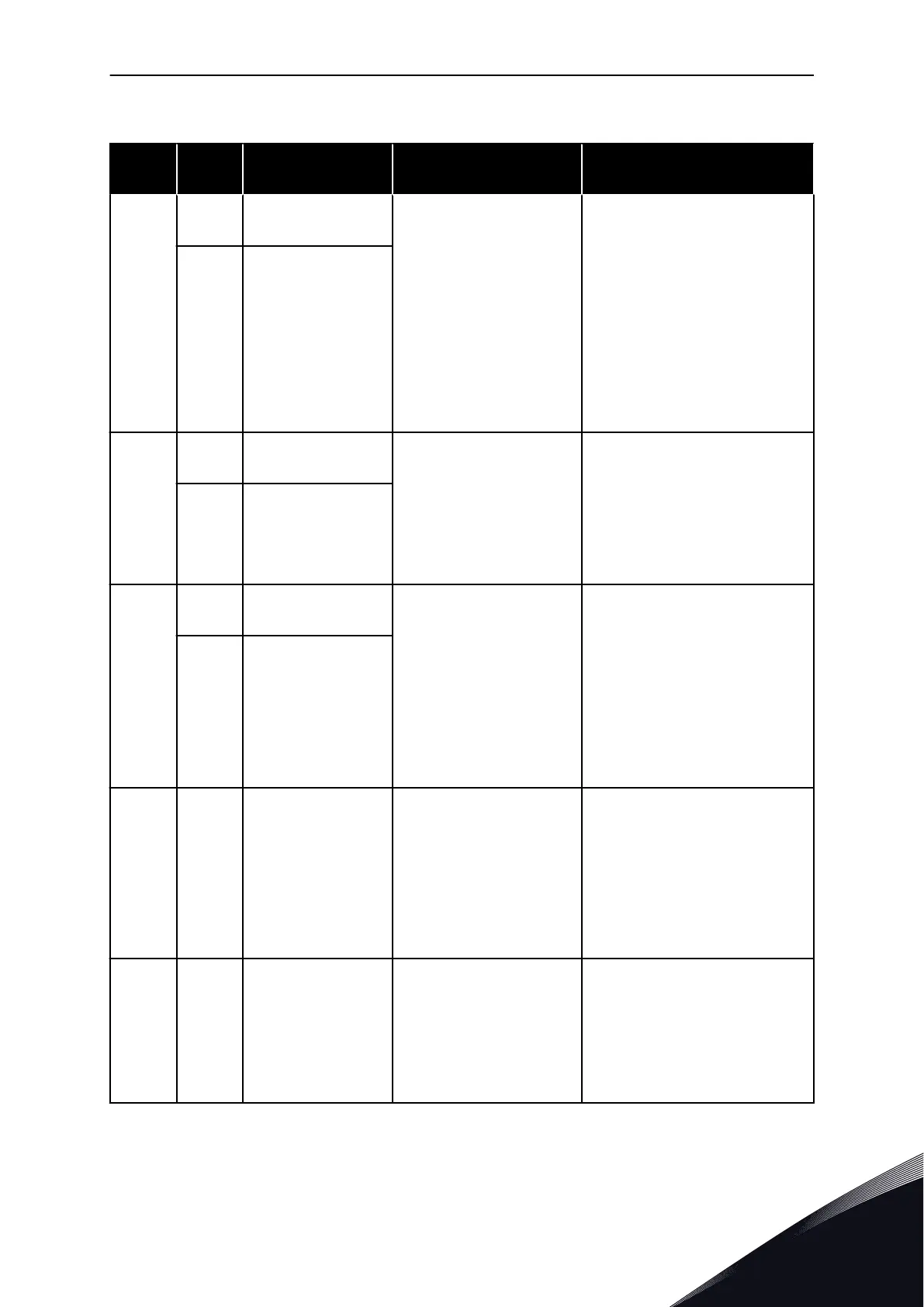

11.3 FAULT CODES

Fault

code

Fault ID Fault name Possible cause How to correct the fault

1 1 Overcurrent (hard-

ware fault)

There is too high a current

(>4*I H) in the motor cable.

Its cause can be 1 of these.

•

a sudden heavy load

increase

•

a short circuit in the

motor cables

•

the motor is not the

correct type

•

the parameter settings

are not properly made

Do a check of the loading.

Do a check of the motor.

Do a check of the cables and con-

nections.

Make an identification run.

Set the acceleration time longer

(P3.4.1.2 and P3.4.2.2).

2 Overcurrent (software

fault)

2 10 Overvoltage (hard-

ware fault)

The DC-link voltage is

higher than the limits.

•

the deceleration time is

too short

•

high overvoltage spikes

in the supply

Set the deceleration time longer

(P3.4.1.3 and P3.4.2.3).

Activate the overvoltage controller.

Do a check of the input voltage.11 Overvoltage (software

fault)

3 20 Earth fault (hardware

fault)

The measurement of cur-

rent tells that the sum of the

motor phase current is not

0.

•

an insulation malfunc-

tion in the cables or the

motor

•

a filter (du/dt, sinus)

malfunction

Do a check of the motor cables and

the motor.

Do a check of the filters.

21 Earth fault (software

fault)

5 40 Charging switch The charging switch is

closed and the feedback

information is OPEN.

•

operation malfunction

•

defective component

Reset the fault and restart the

drive.

Do a check of the feedback signal

and the cable connection between

the control board and the power

board.

If the fault occurs again, ask

instructions from the distributor

near to you.

7 60 Saturation

•

Defective IGBT

•

de-saturation short cir-

cuit in the IGBT

•

a short circuit or an

overload in the brake

resistor

This fault cannot be reset from the

control panel.

Make a power down of the drive.

DO NOT RESTART THE DRIVE or

CONNECT THE POWER!

Ask instructions from the factory.

FAULT TRACING VACON · 365

LOCAL CONTACTS: HTTP://DRIVES.DANFOSS.COM/DANFOSS-DRIVES/LOCAL-CONTACTS/

11

Loading...

Loading...