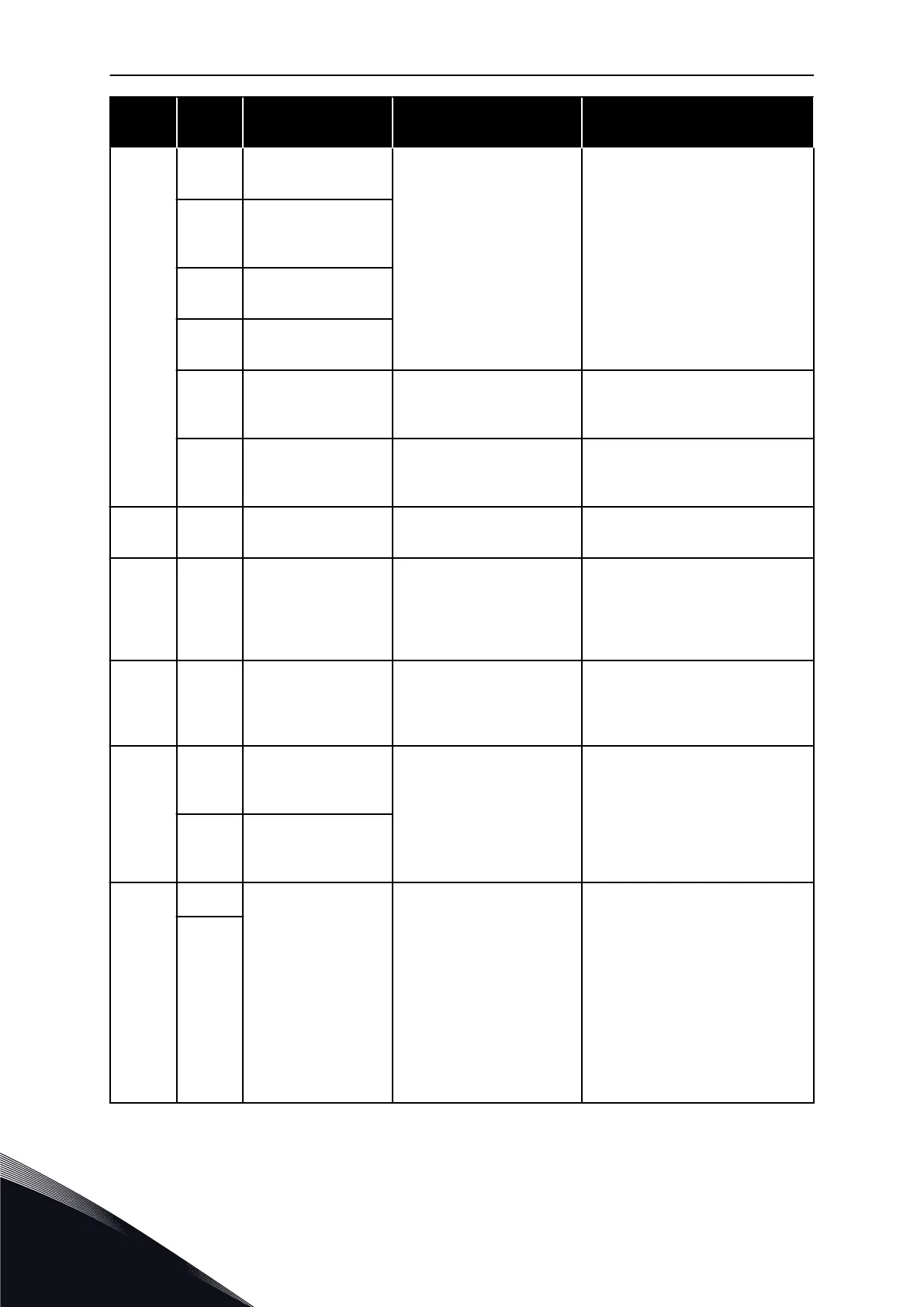

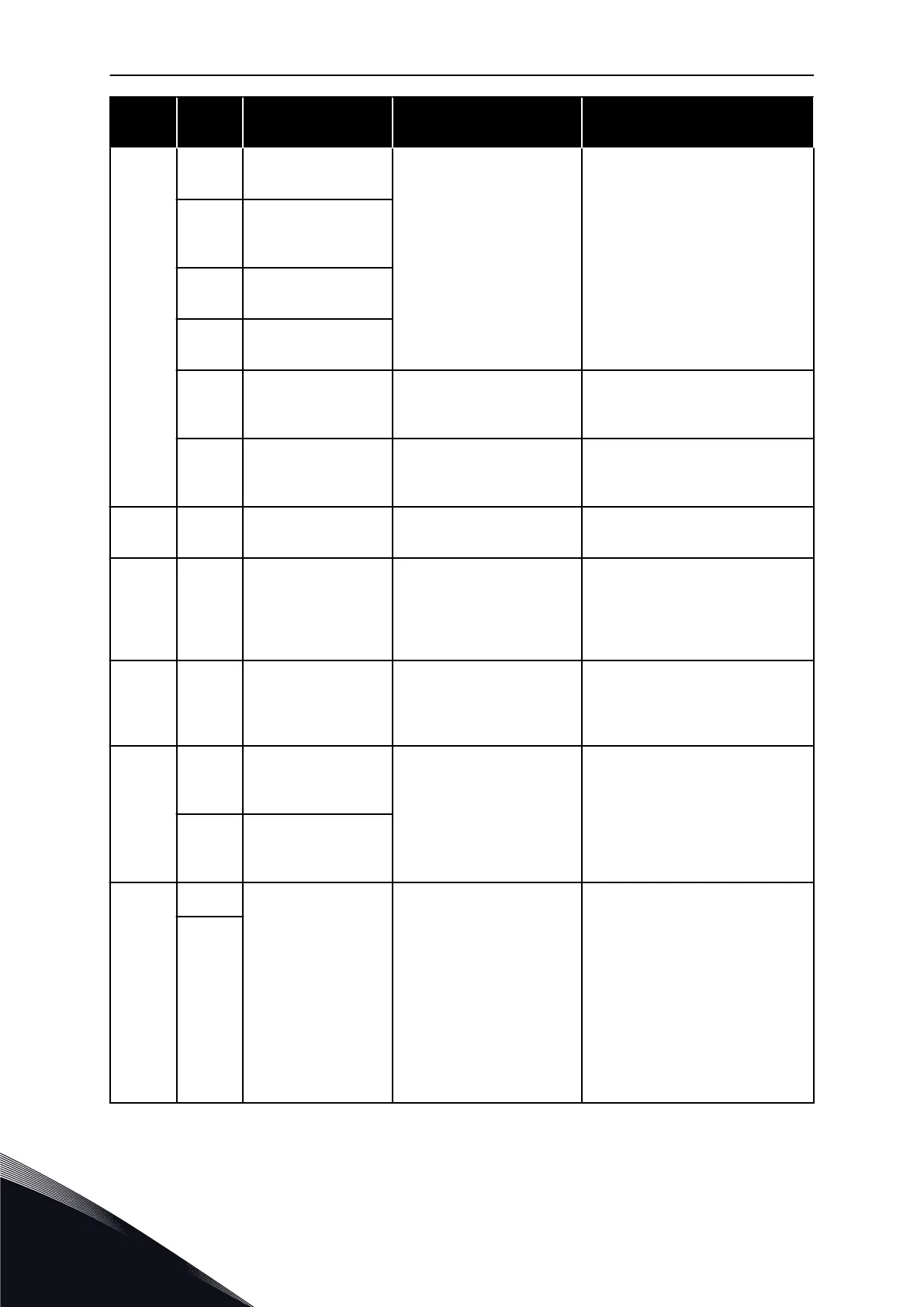

Fault

code

Fault ID Fault name Possible cause How to correct the fault

14 130 AC drive overtemper-

ature (fault, heatsink)

The temperature is too low

in the heatsink of the power

unit or in the power board.

The temperature limits of

the heatsink are different in

all the frames.

Do a check of the actual quantity

and flow of cooling air.

Examine the heatsink for dust.

Do a check of the ambient temper-

ature.

Make sure that the switching fre-

quency is not too high in relation to

the ambient temperature and the

motor load.

Do a check of the cooling fan.

131 AC drive overtemper-

ature (alarm, heat-

sink)

132 AC drive overtemper-

ature (fault, board)

133 AC drive overtemper-

ature (alarm, board)

136 Overvoltage protec-

tion circuit tempera-

ture (alarm)

Too high an output capaci-

tance or an earth fault in the

floating network.

Do a check of the cables and the

motor.

137 Overvoltage protec-

tion circuit tempera-

ture (fault)

Too high an output capaci-

tance or an earth fault in the

floating network.

Do a check of the cables and the

motor.

15 140 Motor stall The motor stalled. Do a check of the motor and the

load.

16 150 Motor overtempera-

ture

The load is too heavy on the

motor.

Decrease the motor load. If there is

no motor overload, do a check of

the motor thermal protection

parameters (parameter group 3.9

Protections).

17 160 Motor underload The load is not sufficient on

the motor.

Do a check of the load.

Do a check of the parameters.

Do a check of the du/dt and sinus

filters.

19 180 Power overload

(short-time supervi-

sion)

The power of the drive is too

high.

Decrease the load.

Examine the dimensioning of the

drive. Examine if it is too small for

the load.

181 Power overload

(long-time supervi-

sion)

25 240 Motor control fault This fault is available only if

you use a customer-specific

application. A malfunction in

the start angle identifica-

tion.

•

The rotor moves during

identification.

•

The new angle does not

agree with the old

value.

Reset the fault and restart the

drive.

Increase the identification current.

See the fault history source for

more information.

241

VACON · 370 FAULT TRACING

11

LOCAL CONTACTS: HTTP://DRIVES.DANFOSS.COM/DANFOSS-DRIVES/LOCAL-CONTACTS/

Loading...

Loading...