P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

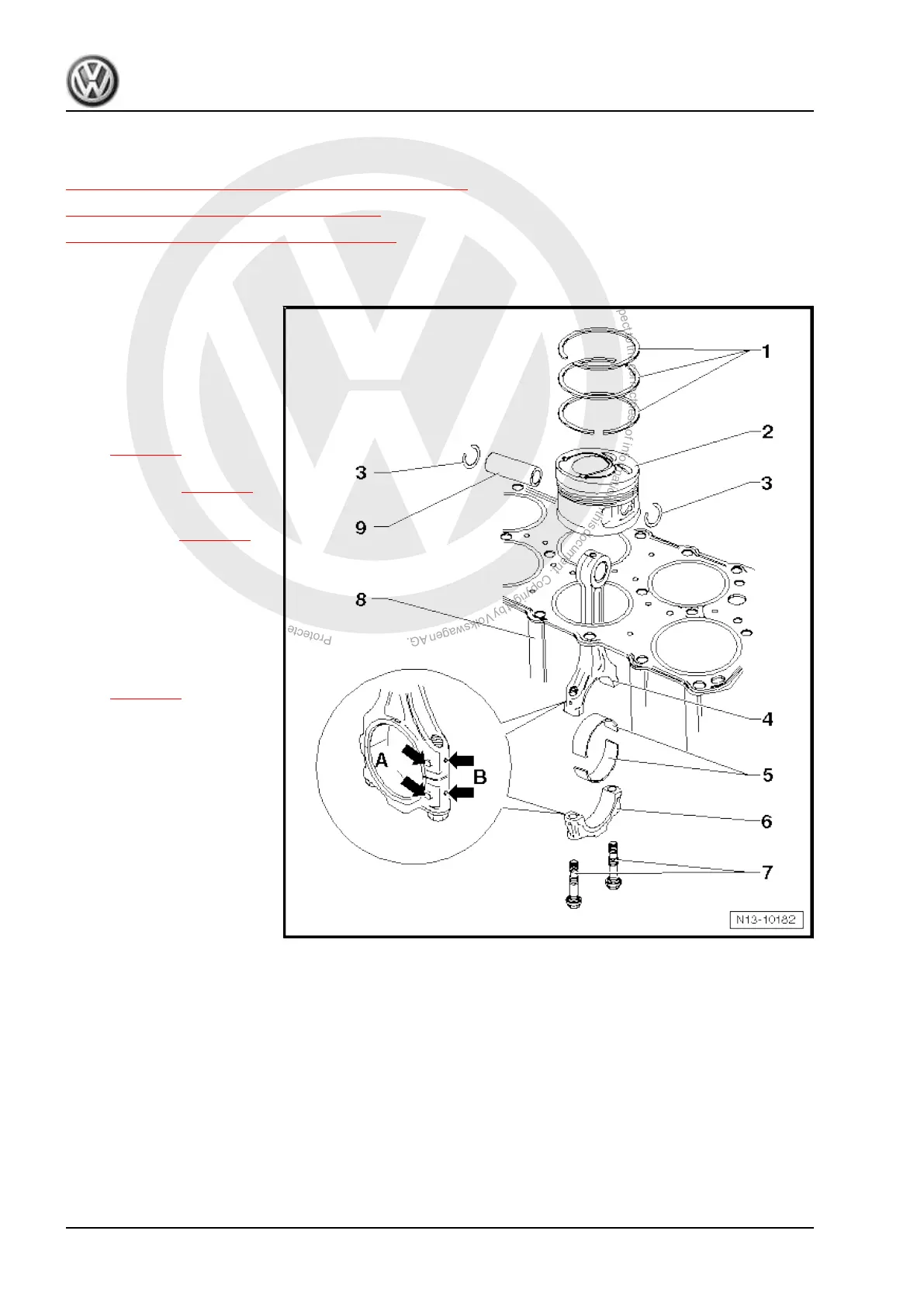

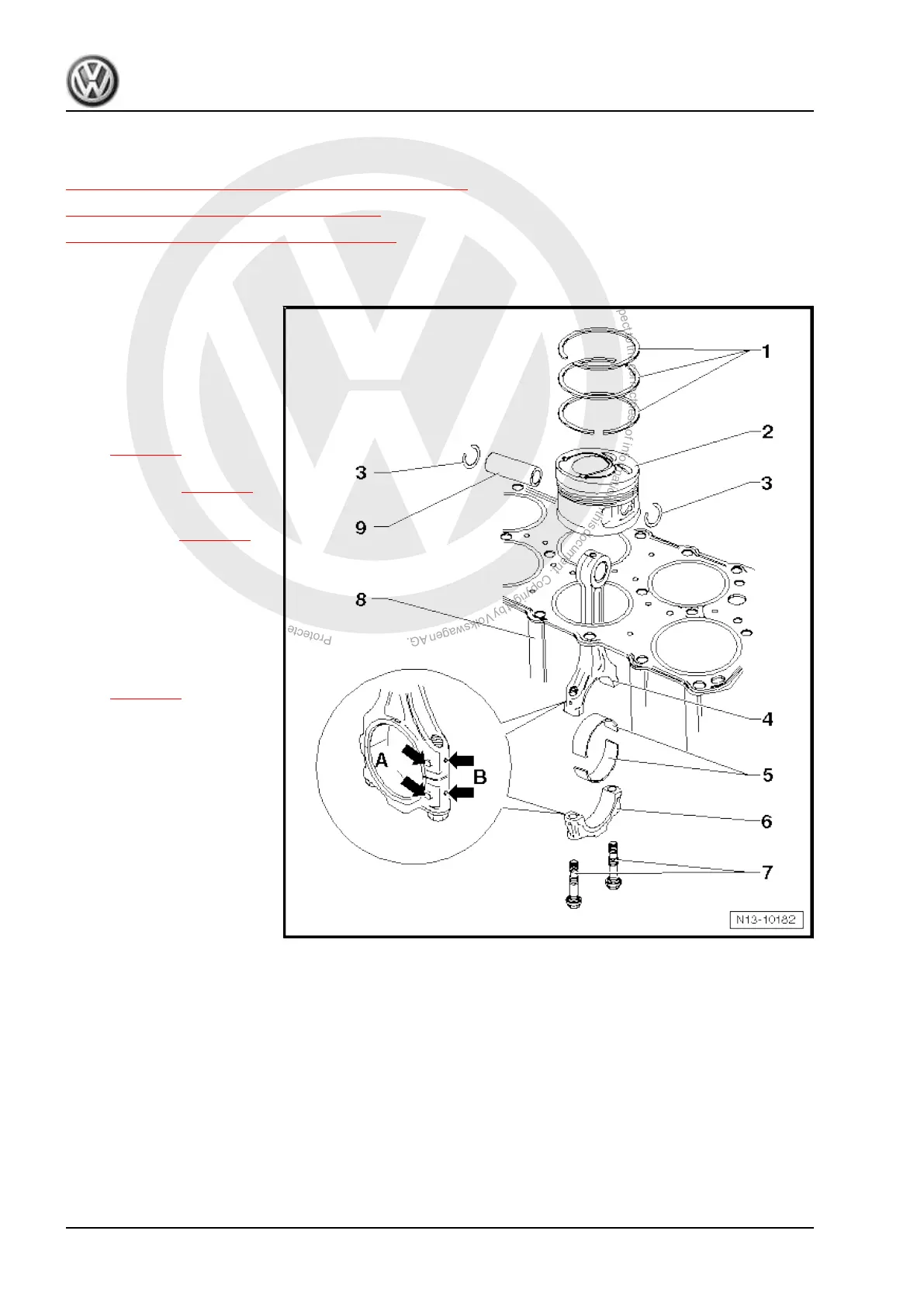

4 Pistons and conrods

⇒ “4.1 Assembly overview - pistons and conrods”, page 56 .

⇒ “4.2 Checking piston and cylinder”, page 57 .

⇒ “4.3 Piston and cylinder dimensions”, page 61

4.1 Assembly overview - pistons and conrods

1 - Piston rings

❑ Offset gaps by 120°

❑ Use piston ring pliers to

remove and install.

❑ “TOP” faces towards

piston crown.

❑ Checking ring gap

⇒ page 57 .

❑ Checking ring-to-groove

clearance ⇒ page 57 .

2 - Piston

❑ Checking ⇒ page 58

❑ Mark cylinder number

and installation position

relative to conrod.

❑ The two deep valve

pockets in the piston

crown point to the centre

of the cylinder block.

❑ Installing piston

⇒ page 58 .

3 - Retaining ring

❑ Ensure firm seating

4 - Connecting rod

❑ Renew as set only.

❑ Mark cylinder number

-B-

❑ Installation position:

marks -A- must be

above one another.

5 - Bearing shell

❑ Observe installation po‐

sition

❑ Do not interchange used bearing shells.

❑ The lugs on bearing shells must fit tightly in the recesses.

❑ Axial clearance new: 0.05 to 0.31 mm; wear limit: 0.40 mm

❑ Measure radial clearance using Plastigage; new: 0.02 to 0.07 mm; wear limit: 0.10 mm. Do not rotate

crankshaft when checking radial clearance.

6 - Conrod bearing cap

❑ Mark cylinder number -B-

❑ Installation position: marks -A- must be above one another.

7 - 40 Nm +

1

/

4

turn (90°) further

❑ Renew

❑ Oil threads and contact surface

Touareg 2010 ➤ , Touareg 2015 ➤

6-cylinder direct-injection engine (3.6 l engine, 4V) - Edition 12.2019

56 Rep. gr.13 - Crankshaft group

Loading...

Loading...