PERIODIC MAINTENANCE

3-6

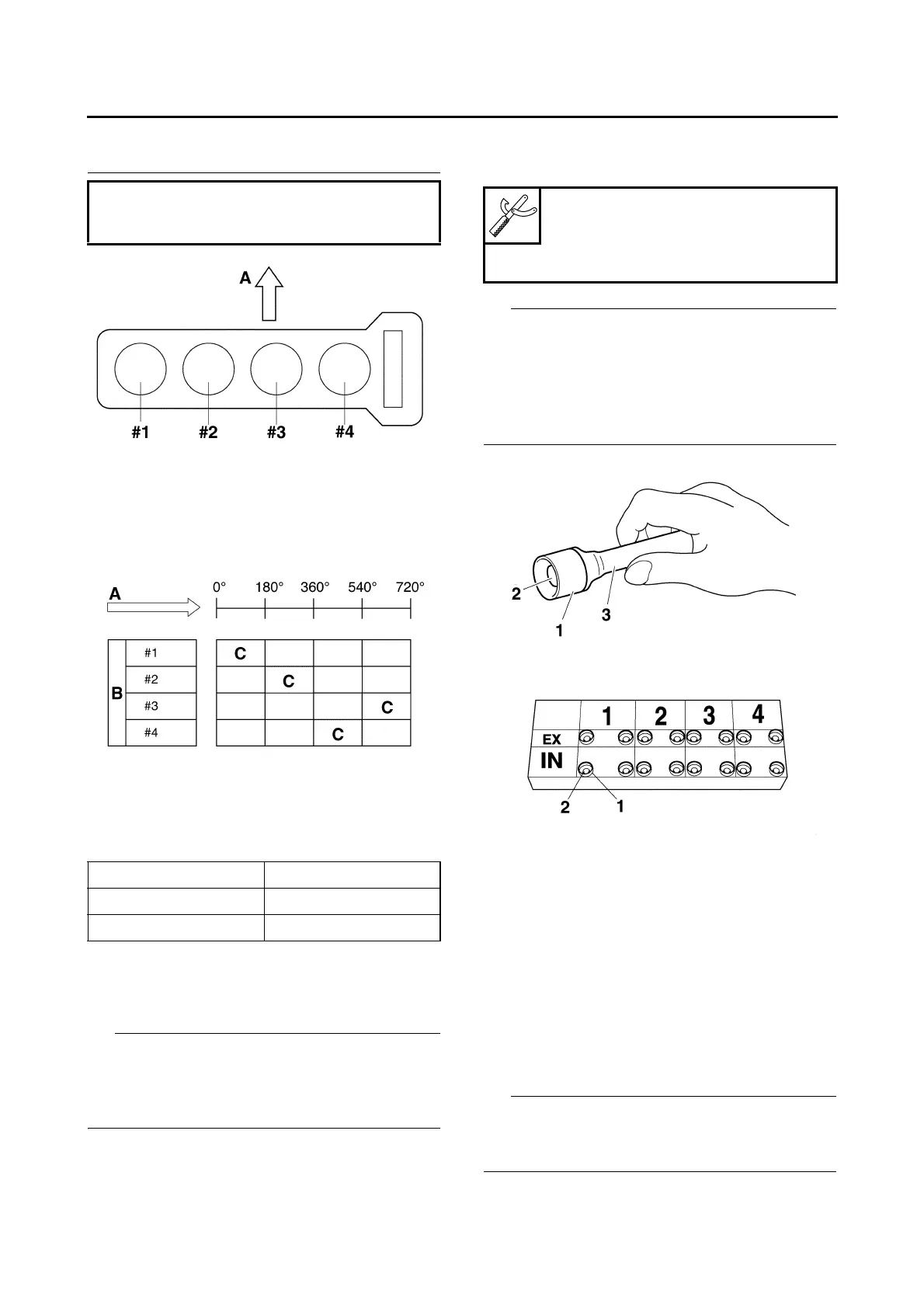

• Measure the valve clearance in the following

sequence.

d. To measure the valve clearances of the other

cylinders, starting with cylinder #1 at TDC,

turn the crankshaft clockwise as specified in

the following table.

▲▲▲▲ ▲ ▲▲▲▲▲▲▲▲▲ ▲ ▲▲▲▲ ▲ ▲▲▲▲ ▲ ▲▲▲▲▲▲▲

5. Remove:

• Camshafts

• Refer to “CAMSHAFTS” on page 5-11.

• When removing the timing chain and cam-

shafts, fasten the timing chain with a wire to re-

trieve it if it falls into the crankcase.

6. Adjust:

• Valve clearance

▼▼▼▼ ▼ ▼▼▼▼▼▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼▼▼

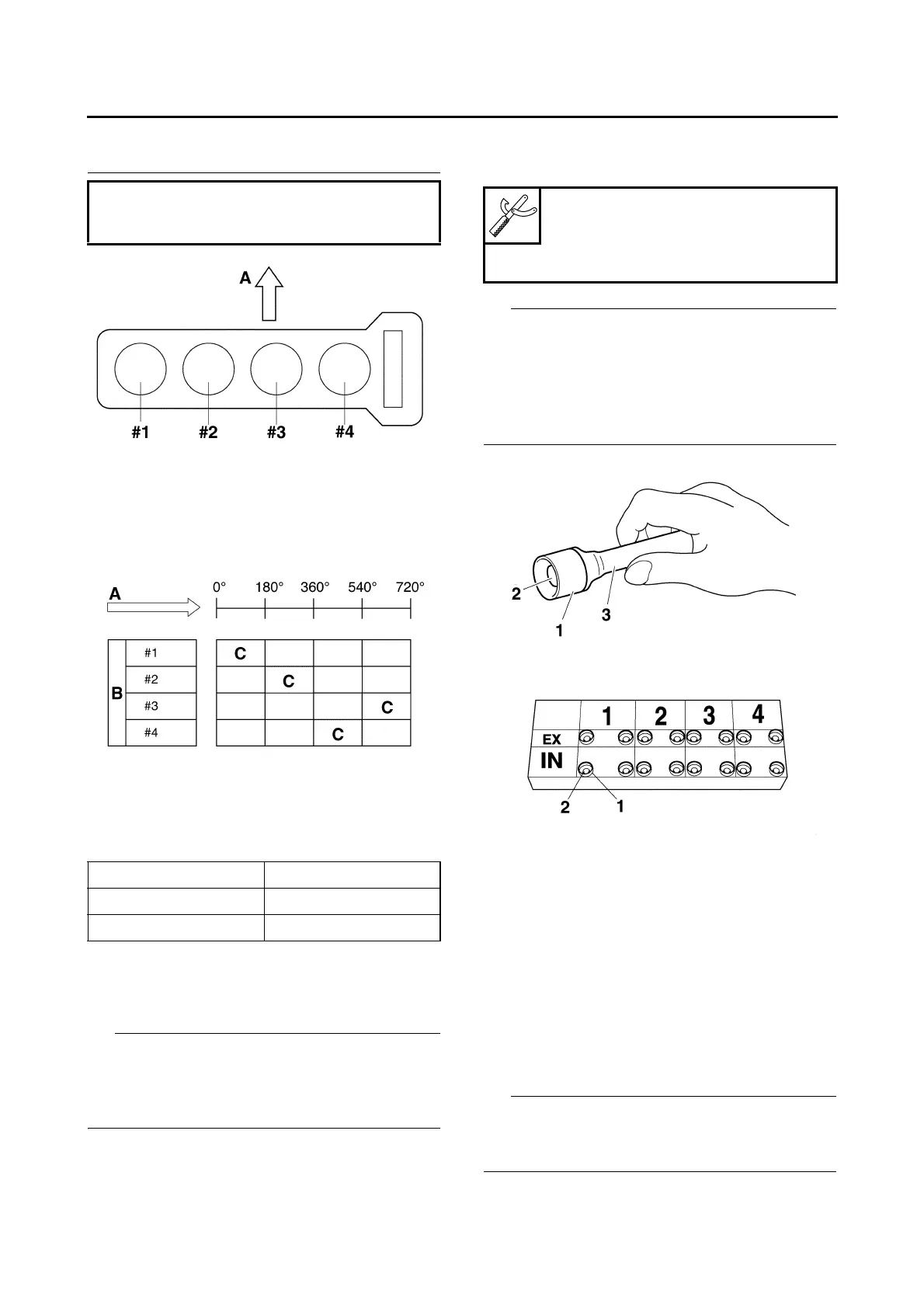

a. Remove the valve lifter “1” and the valve pad

“2” with the valve lapper “3”.

• Cover the timing chain opening with a rag to

prevent the valve pad from falling into the

crankcase.

• Make a note of the position of each valve lifter

“1” and valve pad “2” so that they can be in-

stalled in the correct place.

b. Calculate the difference between the speci-

fied valve clearance and the measured valve

clearance.

Example:

Specified valve clearance = 0.15–0.22 mm

(0.0059–0.0087 in)

Measured valve clearance = 0.25 mm

(0.0098 in)

0.25 mm (0.0098 in) - 0.22 mm (0.0087 in) =

0.03 mm (0.001 in)

c. Check the thickness of the current valve pad.

The thickness “a” of each valve pad is marked in

hundredths of millimeters on the side that touch-

es the valve lifter.

Valve clearance measuring sequence

Cylinder #1 → #2 → #4 → #3

A. Front

A. Degrees that the crankshaft is turned

clockwise

B. Cylinder

C. Combustion cycle

Cylinder #2 180°

Cylinder #4 360°

Cylinder #3 540°

Valve lapper

90890-04101

Valve lapping tool

YM-A8998

Loading...

Loading...