PERIODIC MAINTENANCE

3-5

10.Install:

• T-bar

Refer to “GENERAL CHASSIS” on page 4-1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

• Rider seat

Refer to “GENERAL CHASSIS” on page 4-1.

EAS20490

ADJUSTING THE VALVE CLEARANCE

The following procedure applies to all of the

valves.

• Valve clearance adjustment should be made

on a cold engine, at room temperature.

• When the valve clearance is to be measured or

adjusted, the piston must be at top dead center

(TDC) on the compression stroke.

1. Remove:

• Rider seat

• Right side cowling

Refer to “GENERAL CHASSIS” on page 4-1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

• T-bar

Refer to “GENERAL CHASSIS” on page 4-1.

• Air cut-off valve

Refer to “AIR INDUCTION SYSTEM” on

page 7-13.

• Thermostat inlet pipe 1

Refer to “THERMOSTAT” on page 6-6.

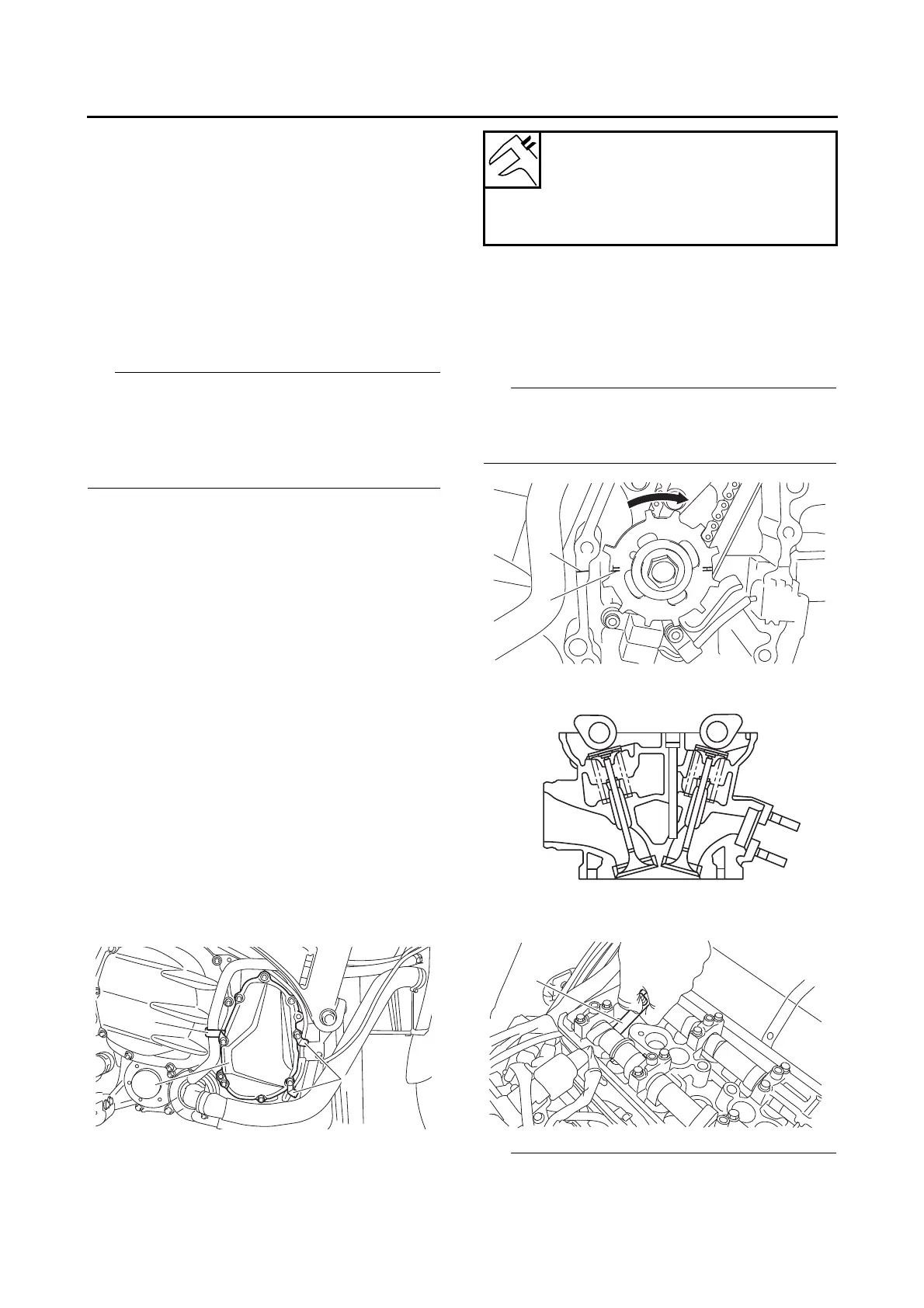

2. Remove:

• Spark plugs

• Cylinder head cover

• Cylinder head cover gasket

Refer to “CAMSHAFTS” on page 5-11.

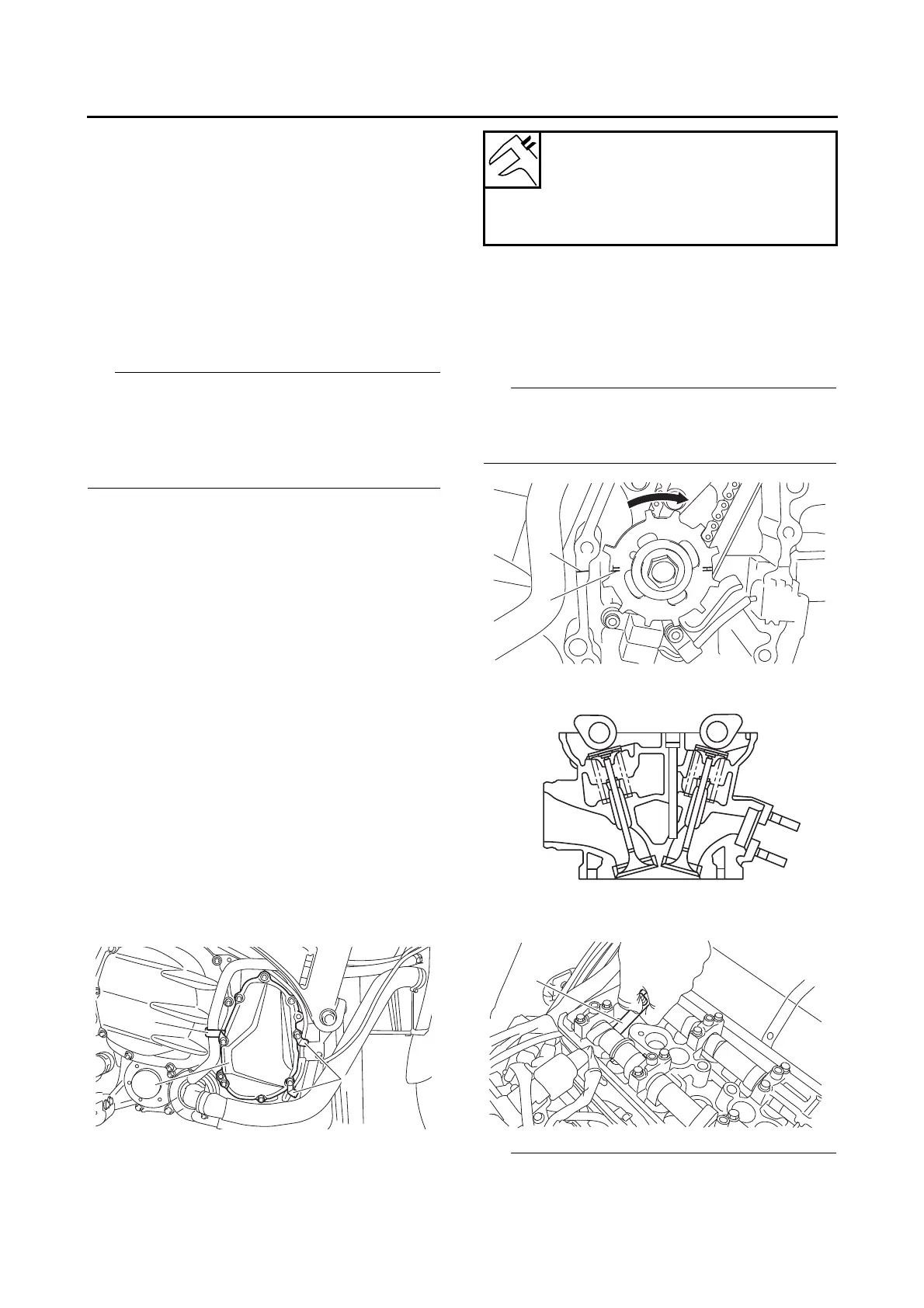

3. Remove:

• Hose holder “1”

• Lead holders “2”

• Pickup rotor cover “3”

4. Measure:

• Valve clearance

Out of specification → Adjust.

▼▼▼▼ ▼ ▼▼▼▼▼▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼▼▼

a. Turn the crankshaft clockwise.

b. When piston #1 is at TDC on the compres-

sion stroke, align the TDC mark “a” on the

pickup rotor with the crankcase mating sur-

face “b”.

TDC on the compression stroke can be found

when the camshaft lobes are turned away from

each other.

c. Measure the valve clearance with a thickness

gauge “1”.

• If the valve clearance is incorrect, record the

measured reading.

Valve clearance (cold)

Intake

0.15–0.22 mm (0.0059–0.0087 in)

Exhaust

0.18–0.25 mm (0.0071–0.0098 in)

1

Loading...

Loading...