6.17 Forcing the Motor to Stop

6.17.2 Stopping Method Selection for Forced Stops

6-107

Stopping the Servomotor by Setting Emergency Stop

Torque (Pn406)

To stop the Servomotor by setting emergency stop torque, set Pn406 (Emergency Stop

Torque).

If Pn001 = n.X is set to 1 or 2, the Servomotor will be decelerated to a stop using the

torque set in Pn406 as the maximum torque.

The default setting is 800%. This setting is large enough to allow you to operate the Servomo-

tor at the maximum torque. However, the maximum emergency stop torque that you can actu-

ally use is the maximum torque of the Servomotor.

* Set a percentage of the motor rated torque.

Stopping the Servomotor by Setting the Deceleration Time

for Servo OFF and Forced Stops (Pn30A)

To specify the Servomotor deceleration time and use it to stop the Servomotor, set Pn30A

(Deceleration Time for Servo OFF and Forced Stops).

If you set Pn30A to 0, the Servomotor will be stopped with a zero speed.

The deceleration time that you set in Pn30A is the time to decelerate the motor from the maxi-

mum motor speed.

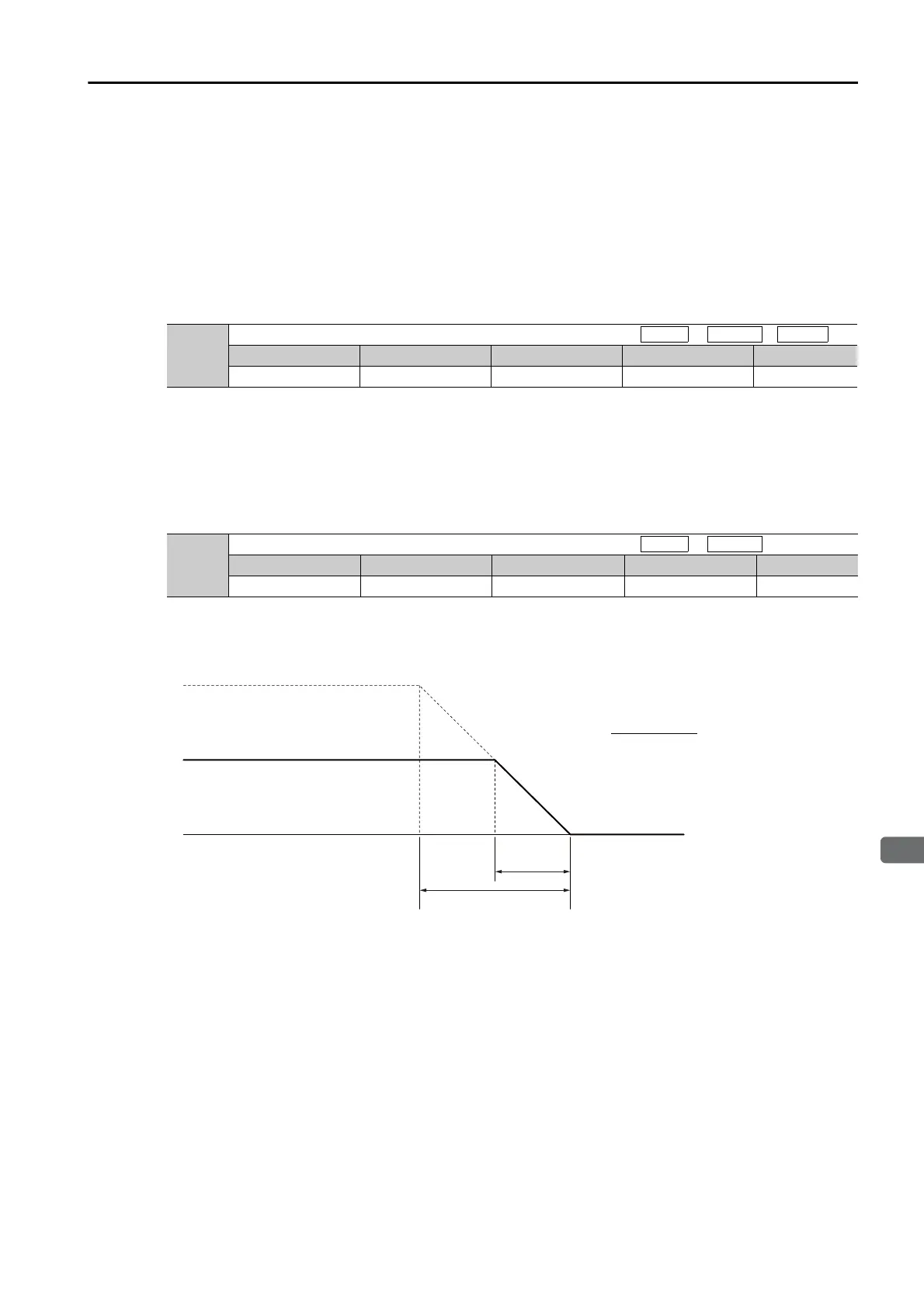

Pn406

Emergency Stop Torque

Setting Range Setting Unit Default Setting When Enabled Classification

0 to 800 1%* 800 Immediately Setup

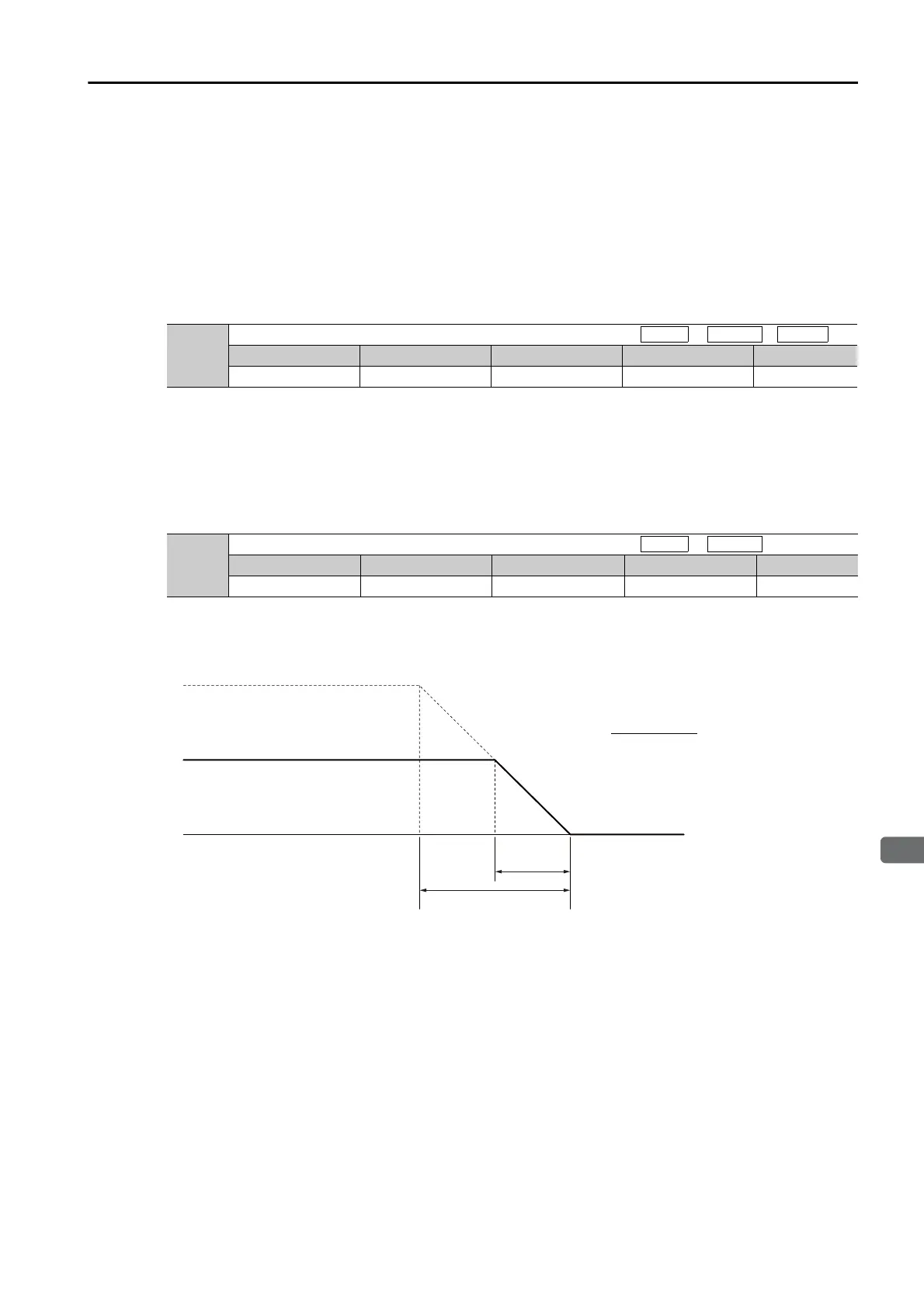

Pn30A

Deceleration Time for Servo OFF and Forced Stops

Setting Range Setting Unit Default Setting When Enabled Classification

0 to 10,000 1 ms 0 Immediately Setup

Pn30A

=

Maximum speed

Operating speed

Actual

deceleration time

Actual deceleration time

Operating speed

Maximum speed

× Deceleration time (Pn30A)

Loading...

Loading...