8210-00020 R1 45

Note

When using Eclectic E6000, pass a heat gun over the belt lacing for a minimum of 2 minutes to

speed up the curing process. If the adhesive begins to bubble, decrease heat intensity.

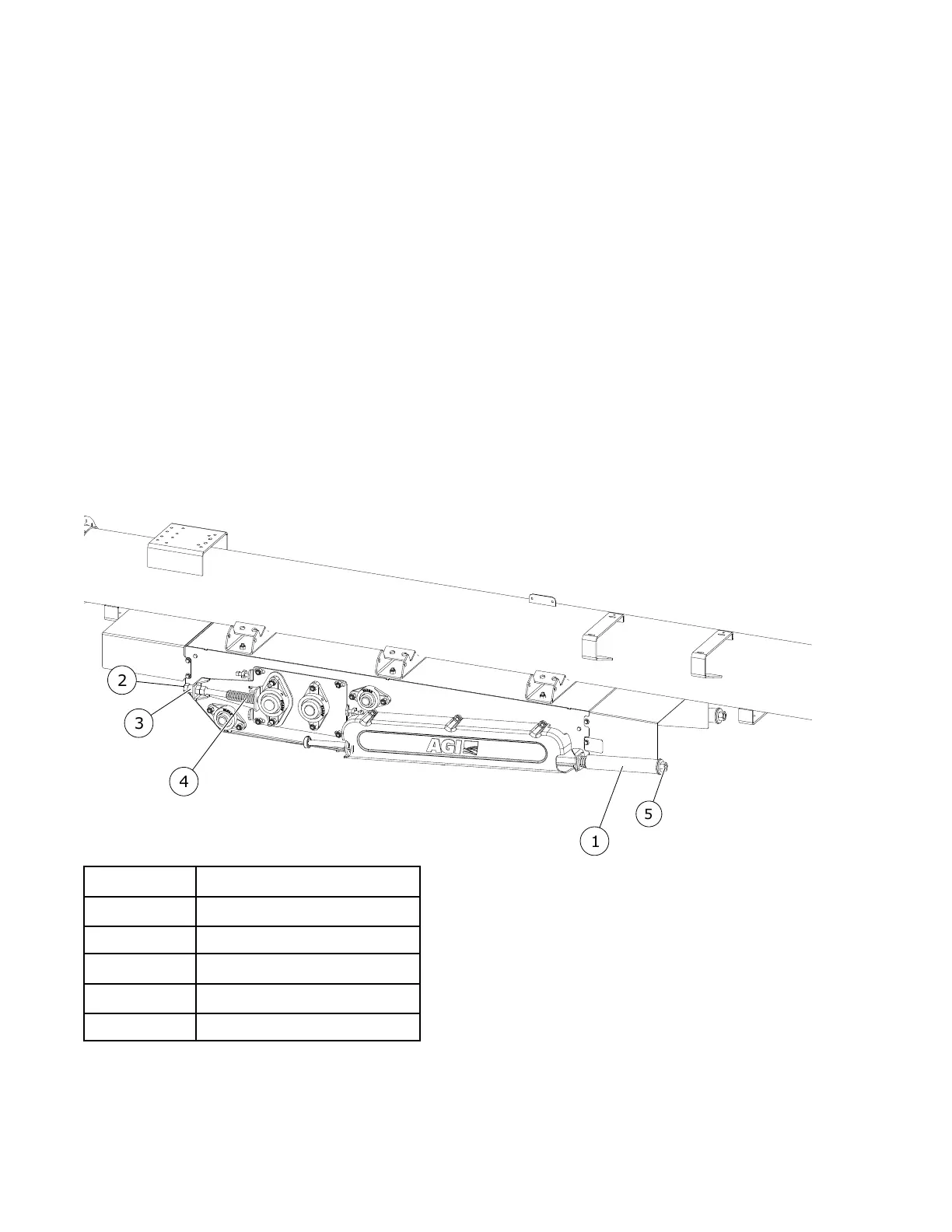

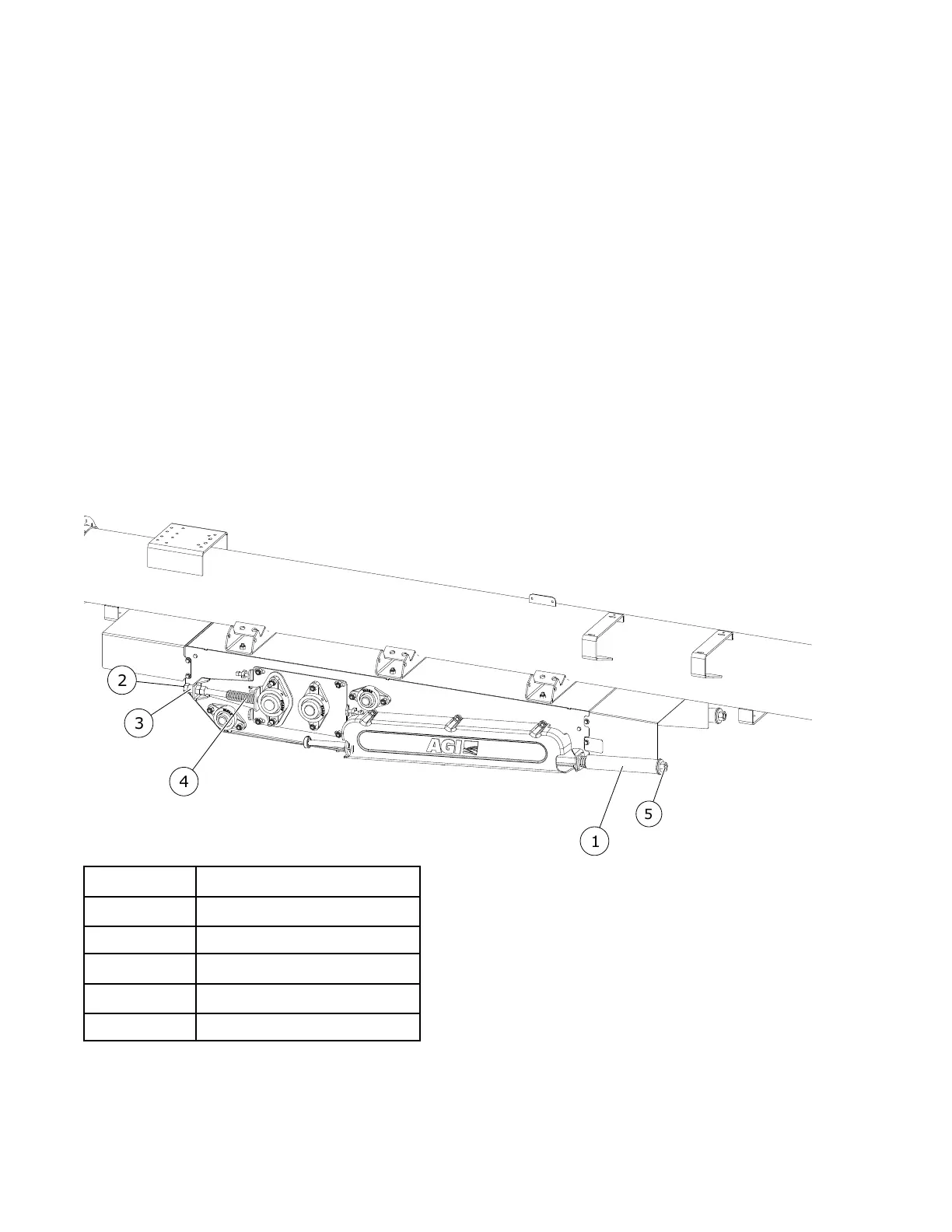

Tighten the Conveyor Belt

Use the s-drive pretensioner assembly (1) to set the belt tension.

1. Tighten the welded nut (5) on the end of the threaded rod until the edge of the pretensioner pipe is within

the green area on the pretensioner decal, see Figure 34.

Important

Alternate sides when adjusting the pretensioner for distances of more than 5”. If one side is more

than 5” behind or ahead of the other, damage to the threaded rod may occur.

2. Measure to be sure both sides are set at the same position.

3. Tighten the pinch roller bolts (2, both sides of s-drive) until the head of bolt contacts the pinch pipe (3).

4. Check to make sure the bolts on the pinch roller bearings are just loose enough to allow the pinch roller to

kick back 1/4" during operation (when the belt seam passes through).

5. Re-attach the s-drive bottom guards.

Figure 33. S-Drive Pretensioner and Pinch Roller Bolts

Item

Description

1

Pretensioner Assembly

2

Pinch Roller Bolt

3

Pinch Pipe

4

Spring

5

Welded Nut

FIELD LOADER S-DRIVE – PORTABLE GRAIN BELT CONVEYOR 3. ASSEMBLY

Loading...

Loading...