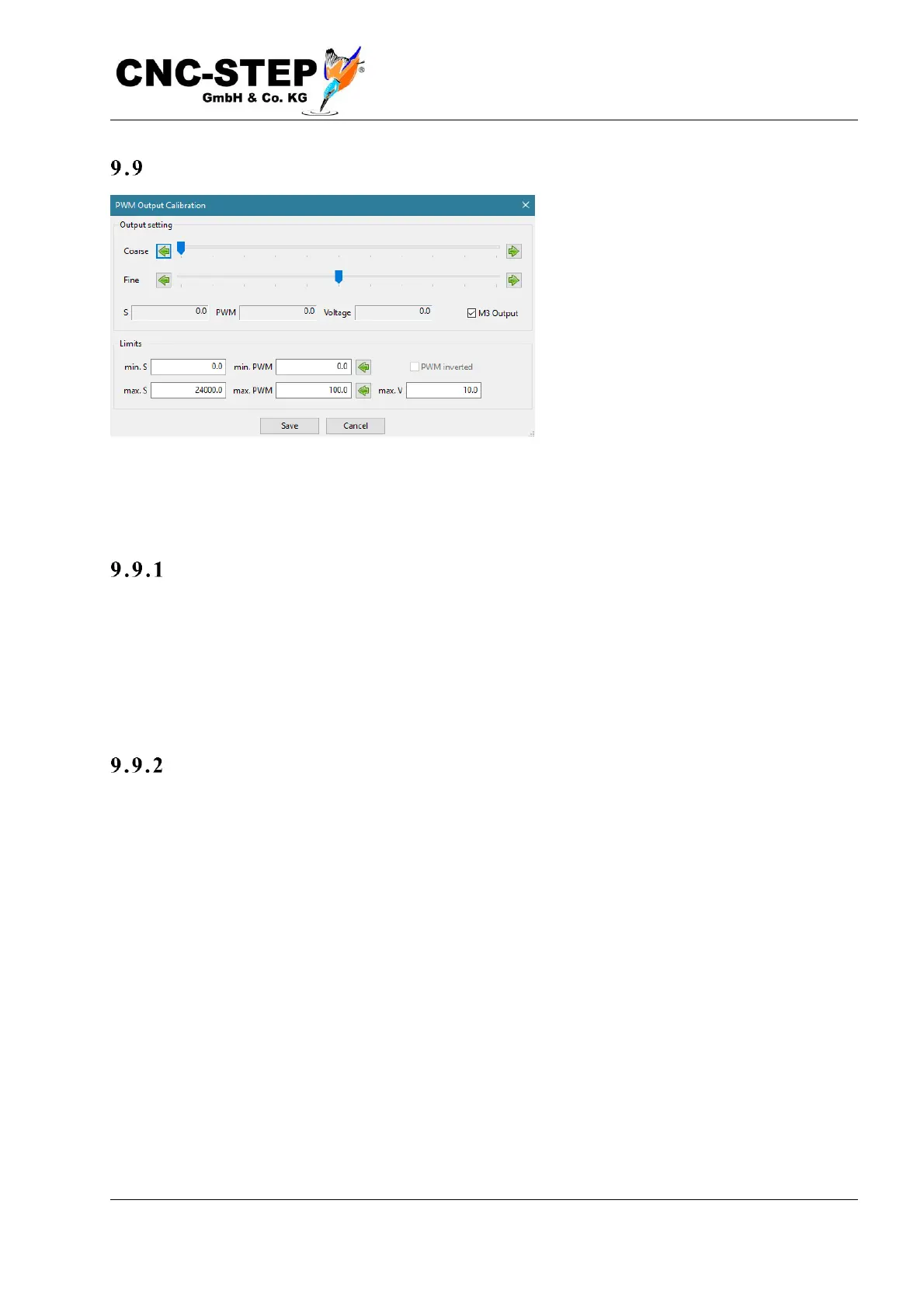

Calibration - PWM output

In the case of milling machines with a

high-frequency spindle, the spindle

speed is set using the PWM output or the

laser power during laser engraving. The

mapping of the S value in the NC

program can be adjusted via the

calibration function, it is set which

minimum and maximum S value

corresponds to which voltage value.

To do this, first enter the permissible range for the S value (speed or power level) at the bottom left.

The middle column shows the assigned values for the minimum and maximum duty cycle of the

PWM output in percent. The value for the maximum voltage at the bottom right is just for control.

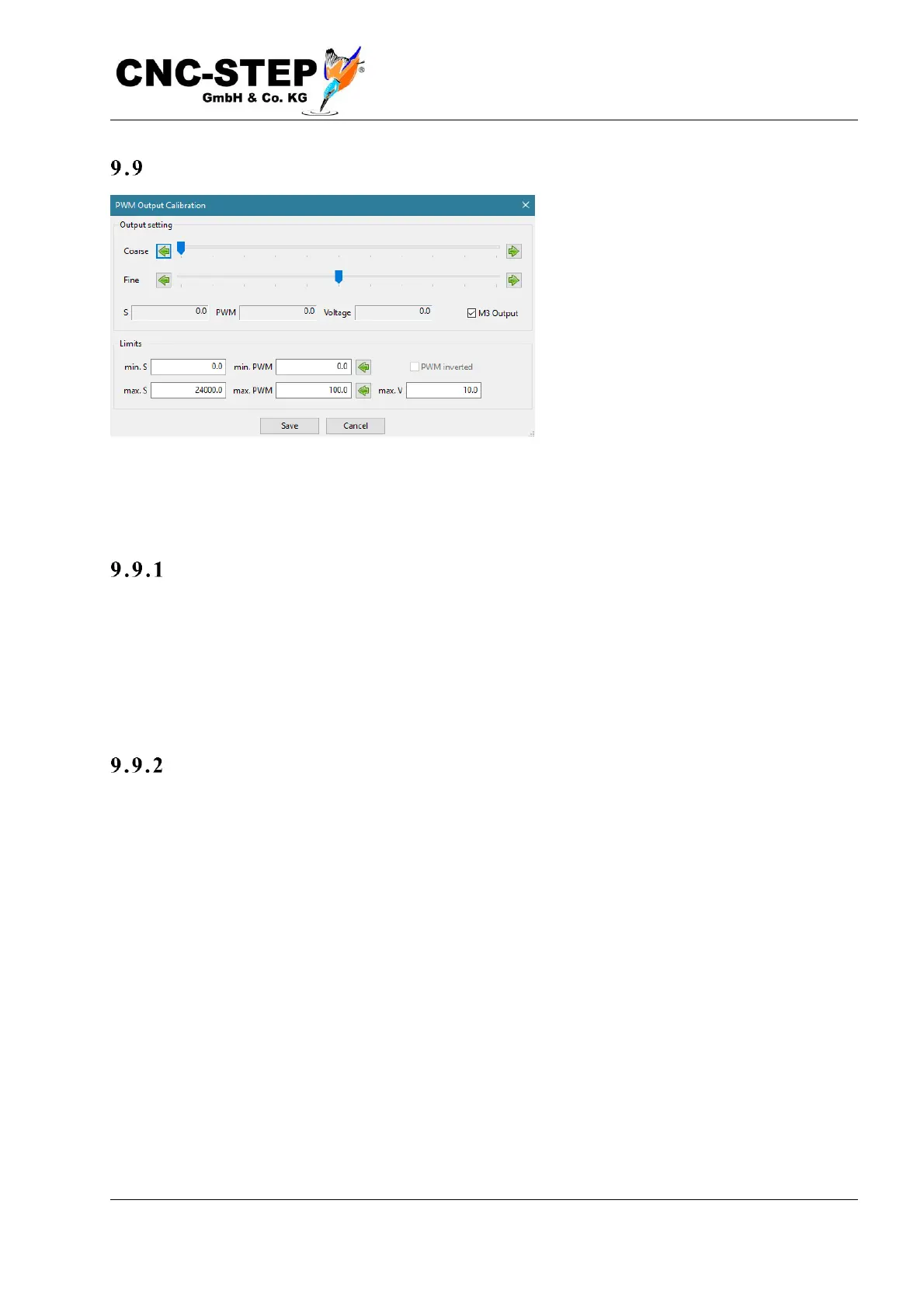

Te sti ng

In the upper part of the window, the setting can be tested. When the M3 output is turned on, the

spindle should rotate at the indicated speed, or the displayed voltage at the analog output should be

measured. If this deviates, it can be adjusted by adjusting the values for min and max PWM. The

arrow button to the right of the PWM values adopts the currently set value from the upper area in

the input field to the left.

La se r Applic a t ions

When laser engraving, the output cannot be tested directly because a hole would burn into the

material when the laser is stationary. Here, the PWM setting must be determined with a special test

program. This is described in the laser unit manual.

Loading...

Loading...