S tart pro gram at any poin t

Retaining a program at any point carries a certain amount of risk depending on the type of

workpiece, the tool and the machining strategy. In extreme cases, such as a T-slot cutter, which is

located in the middle of the material, no resuming at this point is possible at all, without damaging

workpiece or tool. Since the controller cannot automatically detect such hazards, the responsibility

lies with the operator in such cases. If in doubt, calculate that the tool travels diagonally to the next

machining point with all axes at the same time, in other words under certain circumstances it may

be that there is still raw material on the way there. If you cannot be sure that a collision will not

occur, then rewind until you reach a non-hazardous location, such as a safe Z-height outside of the

material.

For short programs that only run for a few minutes, and if the part is not too valuable, it may not be

worth continuing, and it is better to run the program completely from scratch, instead of risking

another tool break.

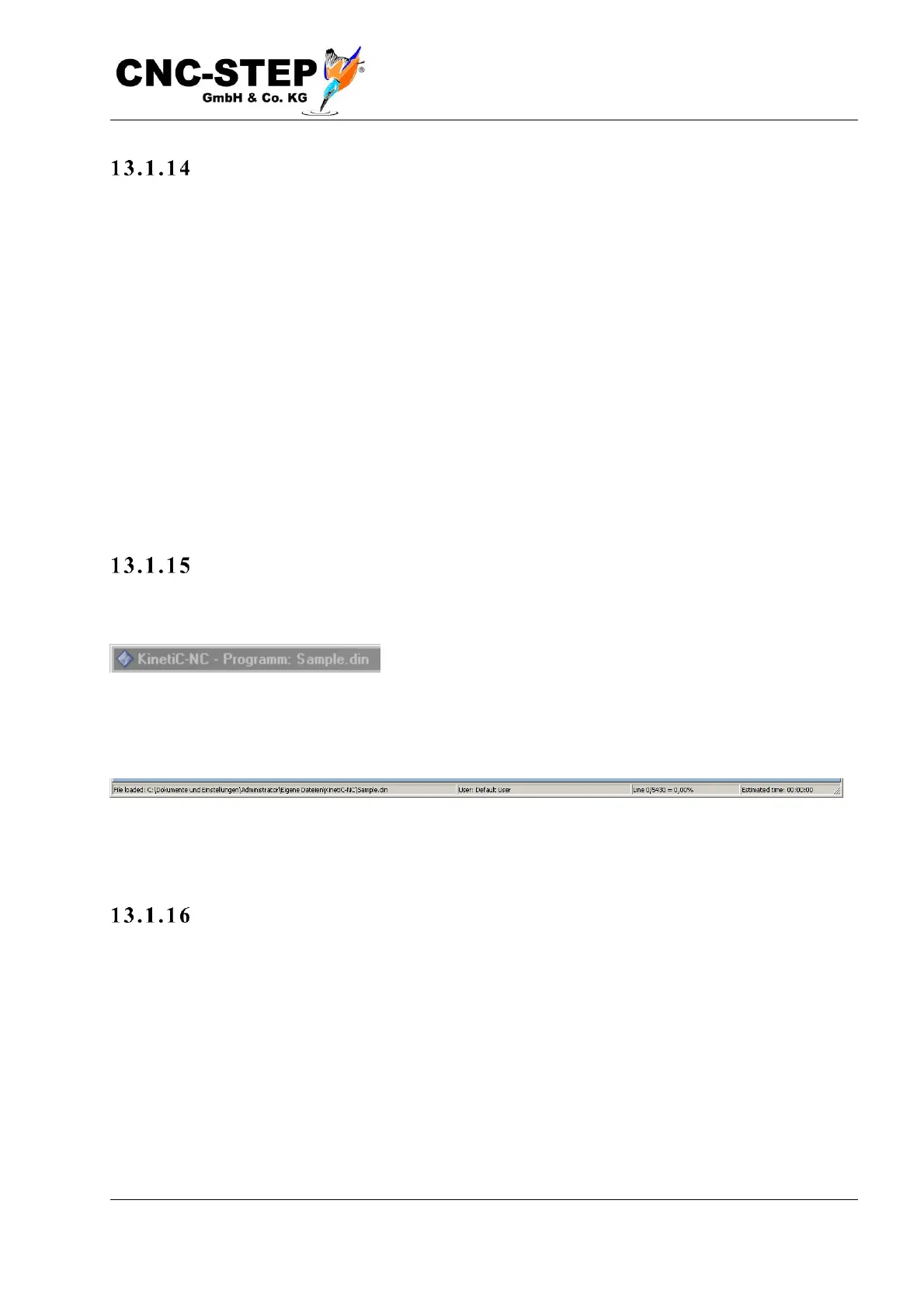

A d diti o nal tip

The title bar at the top of the main window displays the name of the currently loaded program.

The status bar at the bottom left shows the complete pathname of the loaded program. To the right,

the line number is displayed, how far the processing has progressed

If you cancel a program, and If you want to continue the next day, make a note of this line number

to find the right place to continue later.

Execu tio n ti me

At the far right, the preview displays the estimated execution time after loading the program, and

the elapsed time during execution.

Loading...

Loading...