103

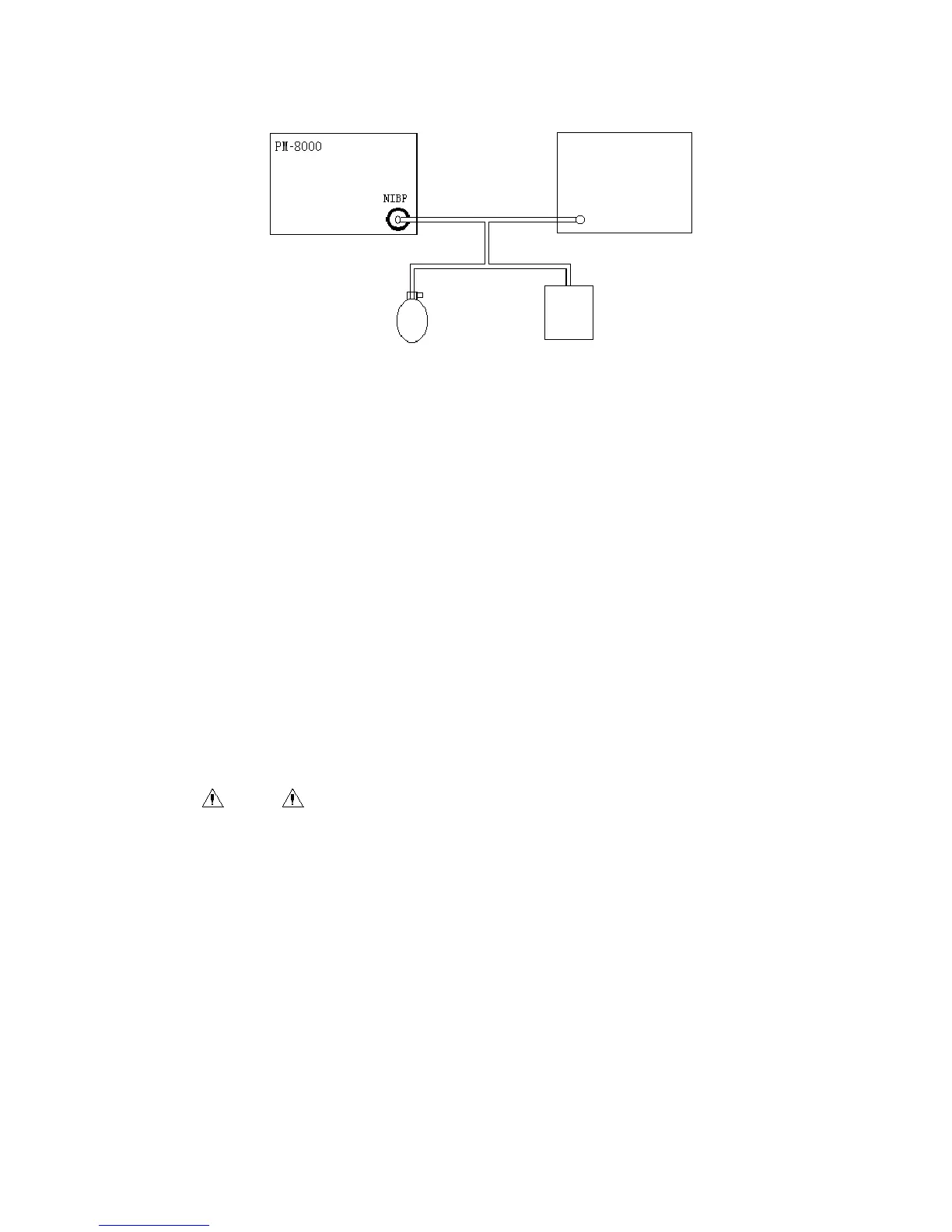

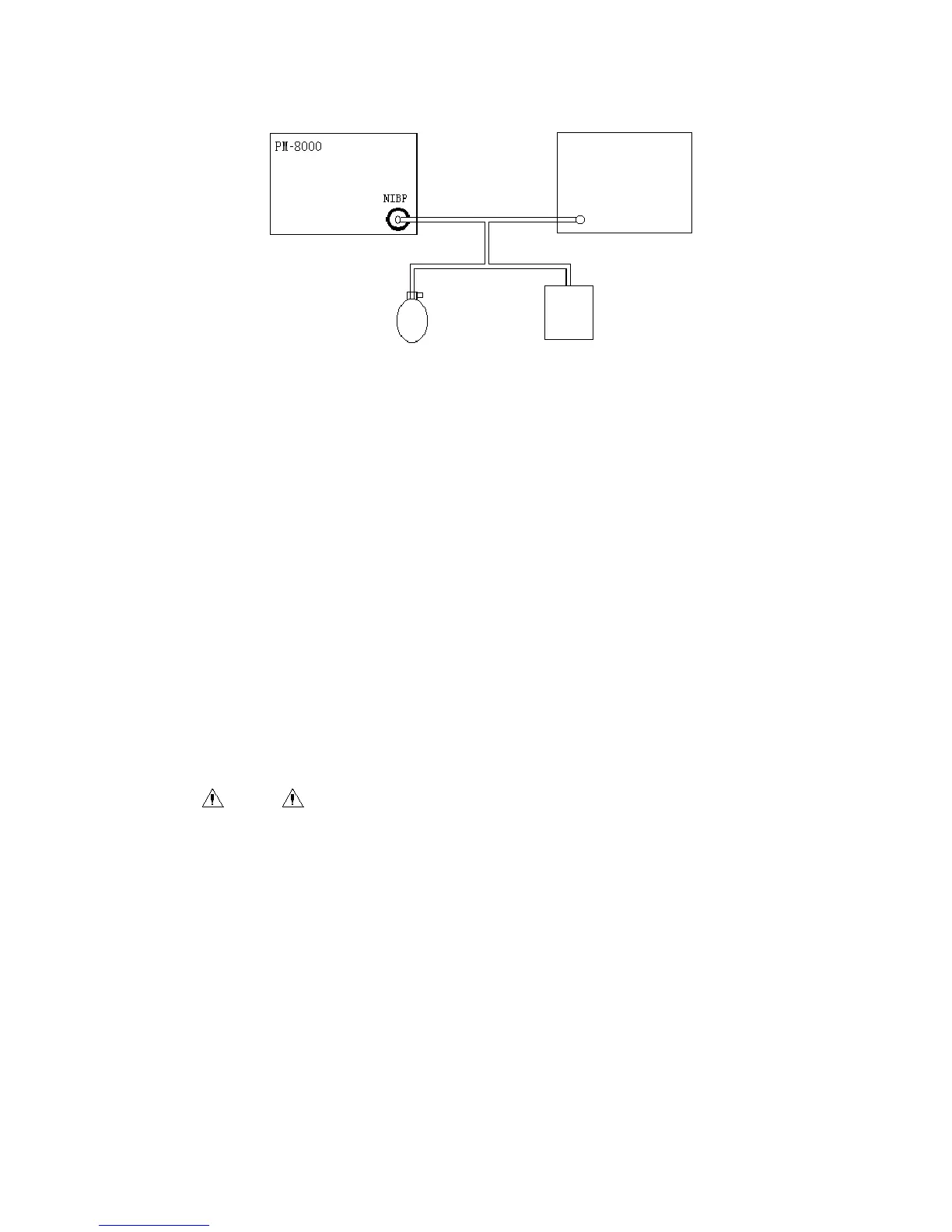

Fig 13-6 Connection for NIBP calibration

14.6 Gas leakage detection

This button is used to detect gas leakage from the NIBP measurement pump. Users, after

connecting with a NIBP cuff, can use this button to start NIBP pumping process so as to observe

whether the NIBP gas route is sealed well. If such a gas leakage test gives a good result, the

system will make no reminder, otherwise there will be the corresponding error reminder in the

NIBP information area.

Default Setting

Users can select this item to enter the “NIBP Default Setting” dialogue box, then further select

“Manufacturer Default” or “User Default”. After making a selection, the system will eject a dialog

box for confirmation of selection by users.

Warning

This gas leakage test, different from as described in the EN 1060-1 Standard, is only for

users to simply detect gas leakage during NIBP pumping process. In case the system

shows there is NIBP gas leakage, please contact with our maintenance engineers.

14.6.1.1 Gas leakage detection process:

Properly connect the cuff with the NIBP hole of the monitor.

Wrap the cuff onto a column body in proper size.

Enter the “NIBP Setting” menu

Rotate the knob, move the cursor onto the “Gas Leakage Detection” item, then press the knob.

There will be a reminder of “Gas leakage detection in progress” at bottom of the NIBP parameter

area of the screen, meaning the system has started executing gas leakage detection

The system automatically pumps to the pressure of 180mmHg.

Gas pipe

Standard

pressure meter

Round pump

Metal vessel

Loading...

Loading...