Introduction

8

DX8210 Barcode Scanner

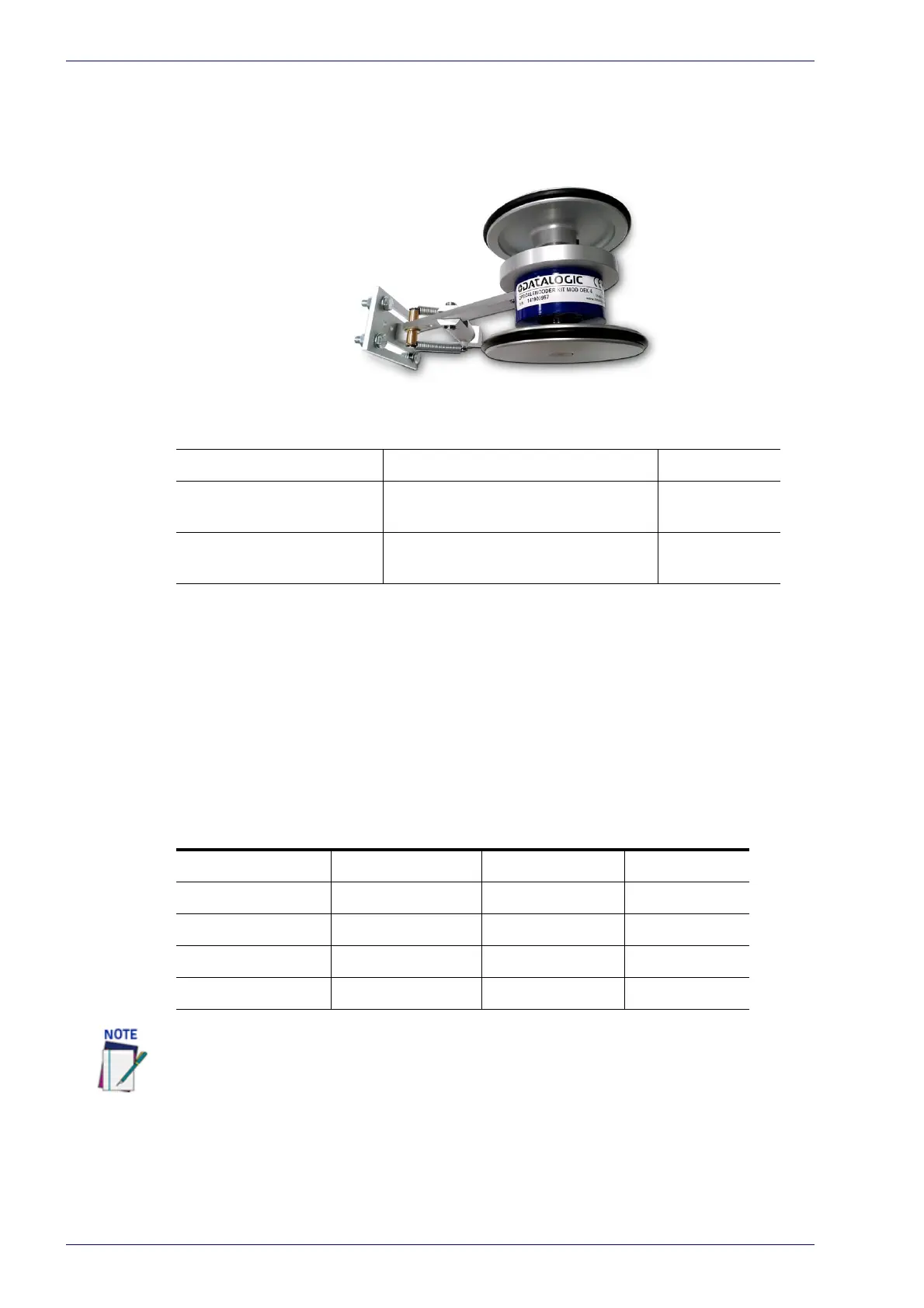

Encoder (Tachometer)

The tachometer provides a continuous pulse to the system, which provides feed-

back on conveyor speed and transmit point,

and can be used to help track the

package position along the length of the conveyor.

Encoder (Tachometer)

OEK-2 ENCOD KIT OEK-2 ENC KIT (CAB 10m +SPRING) 93ACC1770

OEK-4 ENCOD KIT

OEK-4 ENC KIT PNP 250PPR + M12-

M1

2 CABLE

95B082040

OEK-4 ENCOD KIT

OEK-4 ENC KIT PNP 250PPR + M12-

FREE

CABLE

95B082050

Encoder/Tachometer Step Settings

The following table shows the Encoder Step setting used based on pulses per

revolution. The Encoder Step setting is entered in e-Genius

(see section Modify

Settings | Global Settings | Operating Mo

de – Encoder Step (hundredths of milli-

meter)).

Encoder Model

PPR

(Pulses Per

Revolution)

PPI

(Pulses Per

Inch)

Encoder Step

Se

tting

OEK-4 (Datalogic) 250 20 63

OEK-2 (Photocraft) 24 2 635

OEK-2 48 4 317

OEK-2 192 16 79

OEK-2 240 20 63

This symbol draws attention to details or procedures that may be useful in improving,

maintaining, or enhancing the performance of the hardware or software being dis-

cussed.

Loading...

Loading...