Barcode Scanning Features

216

DX8210 Barcode Scanner

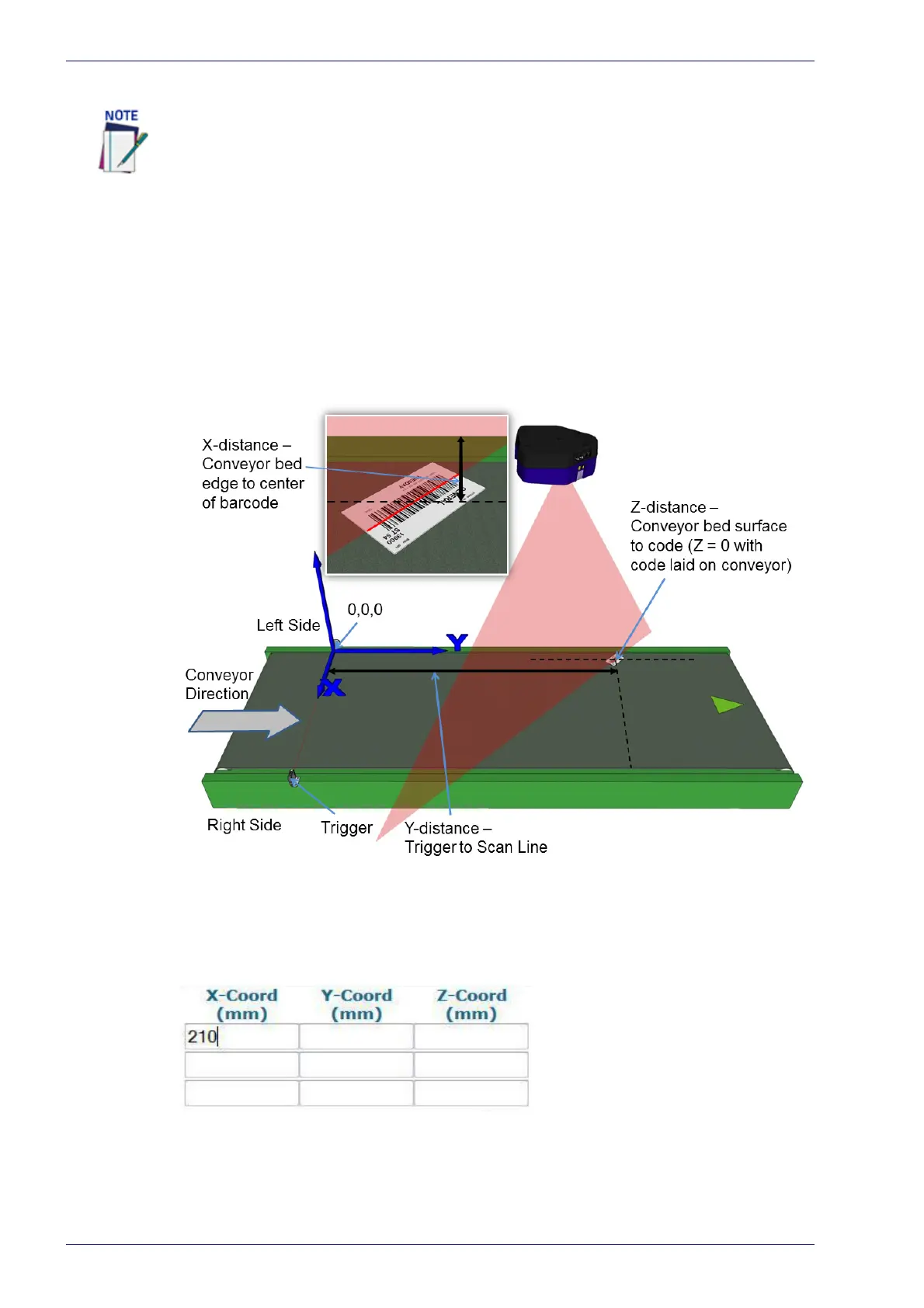

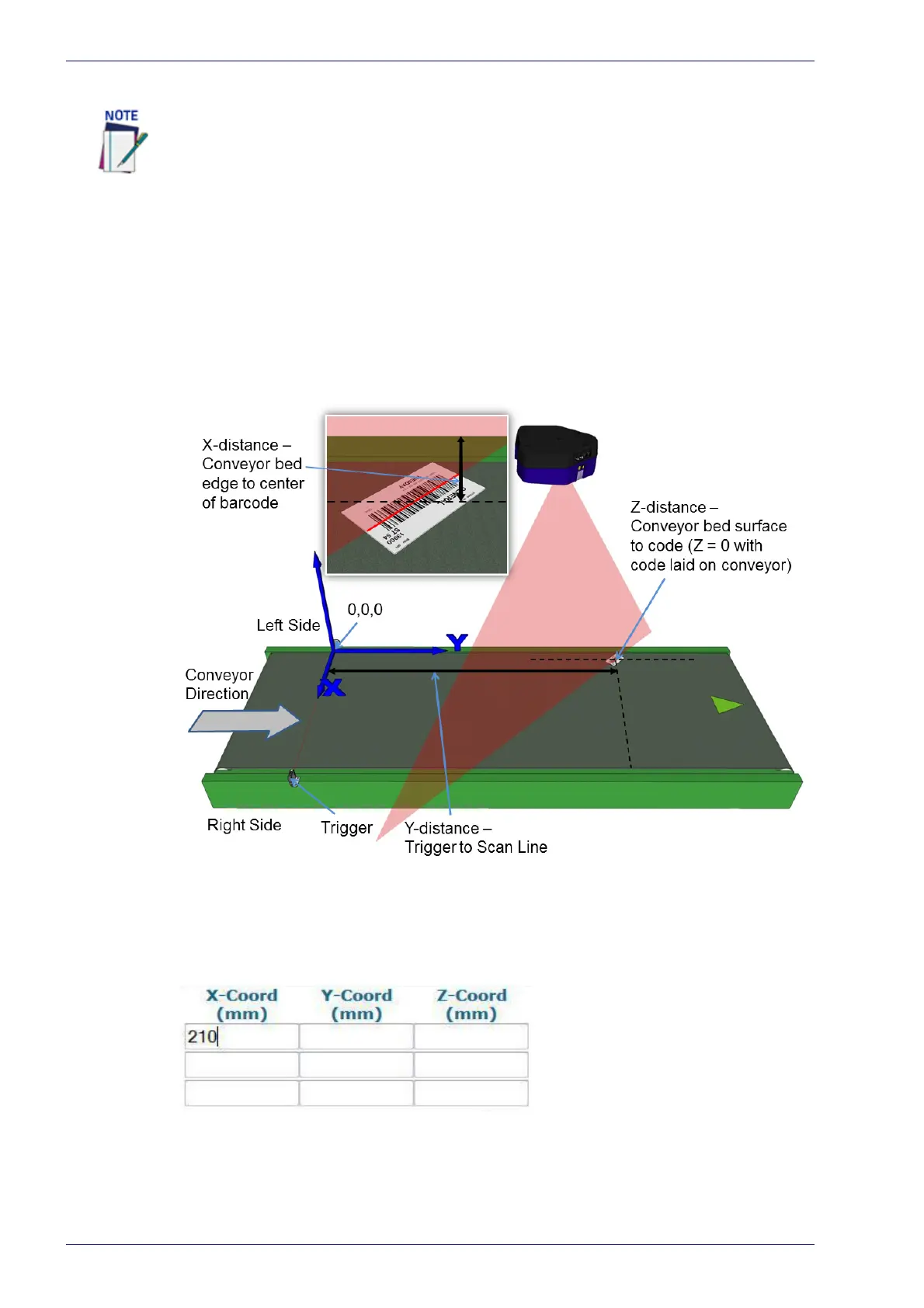

Top-Mounted Barcode Scanner Calibration Using PackTrack

With the belt stopped, measure and enter the barcode XYZ coordinate data for

each scanner as follows:

1. Make sure that the intended scanner (in a multi-head system) and Le

g1

have been selected from the drop-down lists at the top of the wizard win-

dow.

2. Lay a system barcode on the conveyor bed in the laser line close to the left

edge (X=

0 edge) of the conveyor bed. See illustration below.

3. Measure the distance for X from the edge of the conveyor bed to the center

of the barcode, and enter that distance in the first box under X-Coord (mm)

in the PackTrack Calibration Wizard. Your measurements will likely differ

from those shown below.

4. Measure the distance for Y from the trigger (PS line) to the barcode scan-

ner's laser line on the barcode, and enter that distance in the first box

un

der Y-Coord (mm).

It is not possible to illustrate every possible installation angle and scanner mounting

position in this manual. Use the following steps as a general guide to calibrating each

system scanner using barcodes in three positions. You will need to make adjustments

to the label/box position based on your situation. It is, however, important to note the

fixed XYZ coordinates of the conveyor.

Loading...

Loading...