Chapter 12 Description of Parameter Settings

MH300

Pr.02-16–Pr.02-17 Multi-function Output (MO1, 2)

Pr.06-01 Over-voltage stall prevention

Pr.06-03 Over-current stall prevention during acceleration

Pr.06-04 Over-current stall prevention during operation

Pr.06-05 Acceleration / deceleration time selection for stall prevention at constant speed

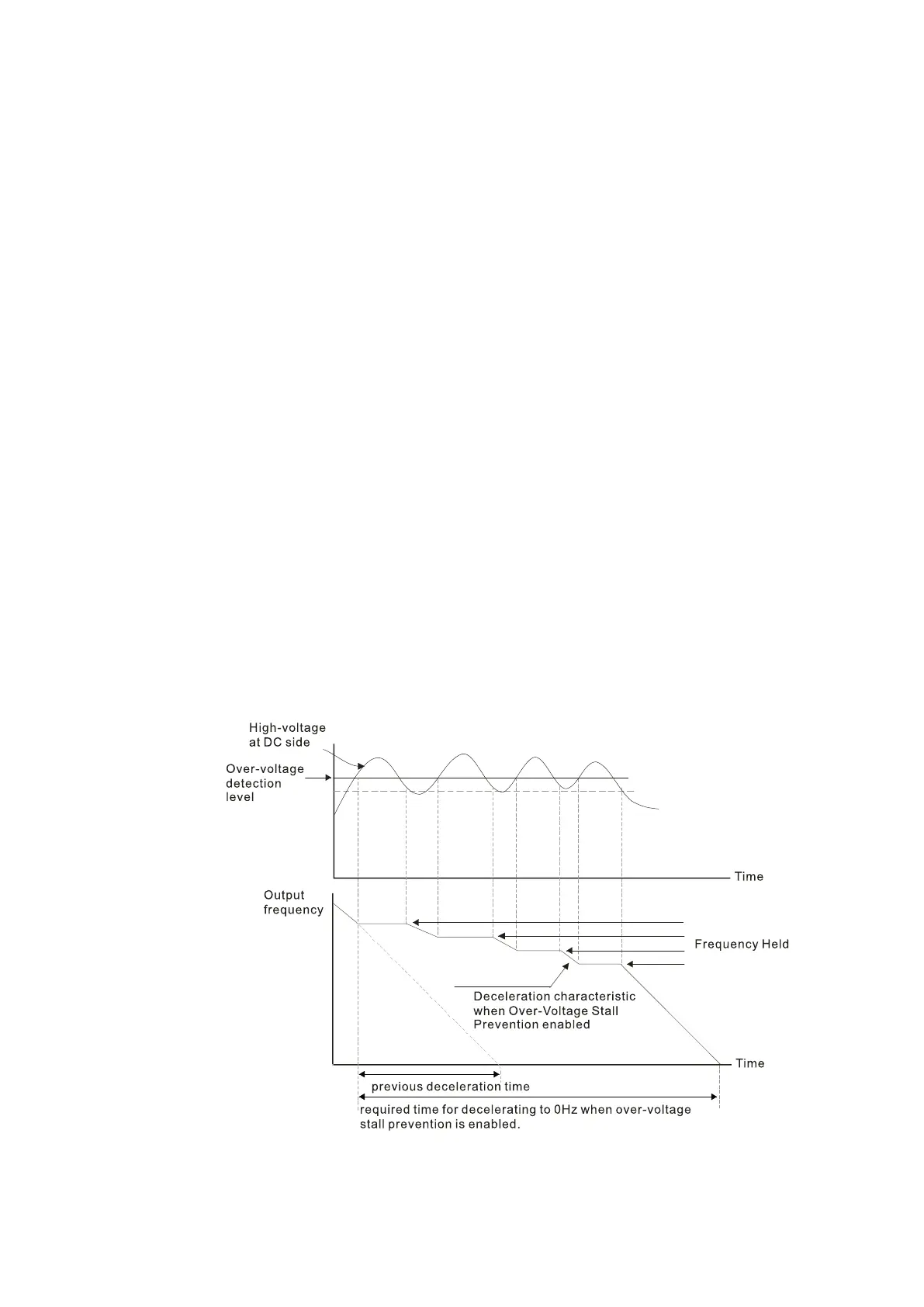

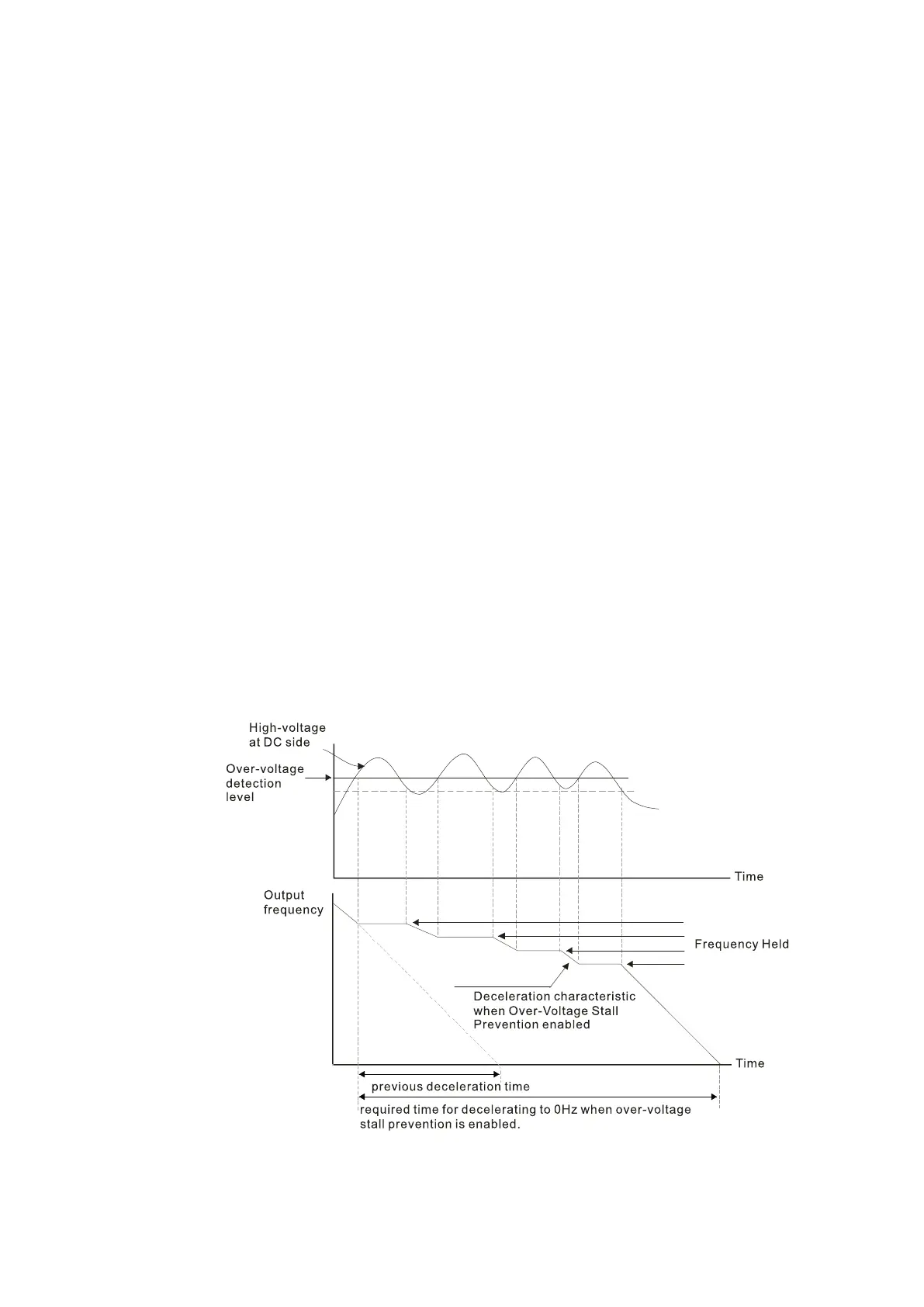

Traditional over-voltage stall prevention

Used for uncertain load inertia. When it stops under normal load, the over-voltage does not occur

during deceleration and fulfills the deceleration time setting. However, load regenerative inertia

may occasionally increase and does not trip due to over-voltage when decelerating to stop. In this

case, the drive automatically increases the deceleration time until it stops.

Because of the motor load inertia, the motor may exceed the synchronous speed when the drive

decelerates; in this case, the motor becomes generator. If the motor load inertia is larger, or the

setting for drive’s decelerating time is too small, the motor regenerates energy to the drive, and

makes the DC bus voltage increase to the maximum allowable value. Thus, when traditional over-

voltage stall prevention is enabled, the drive does not decelerate further and maintains the output

frequency until the voltage drops below the setting value again.

When the over-voltage stall prevention is enabled, the drive deceleration time is larger than the

setting time.

When there is a problem with the deceleration time, this function is disabled. See below for

solution:

1. Increase the deceleration time properly.

2. Install a brake resistor (refer to Section 7-1 Brake Resistors and Brake Units Selection Chart

for details) to dissipate the heat, that is, the electrical energy regenerating from the motor.

Loading...

Loading...