Chapter 12 Description of Parameter Settings

MH300

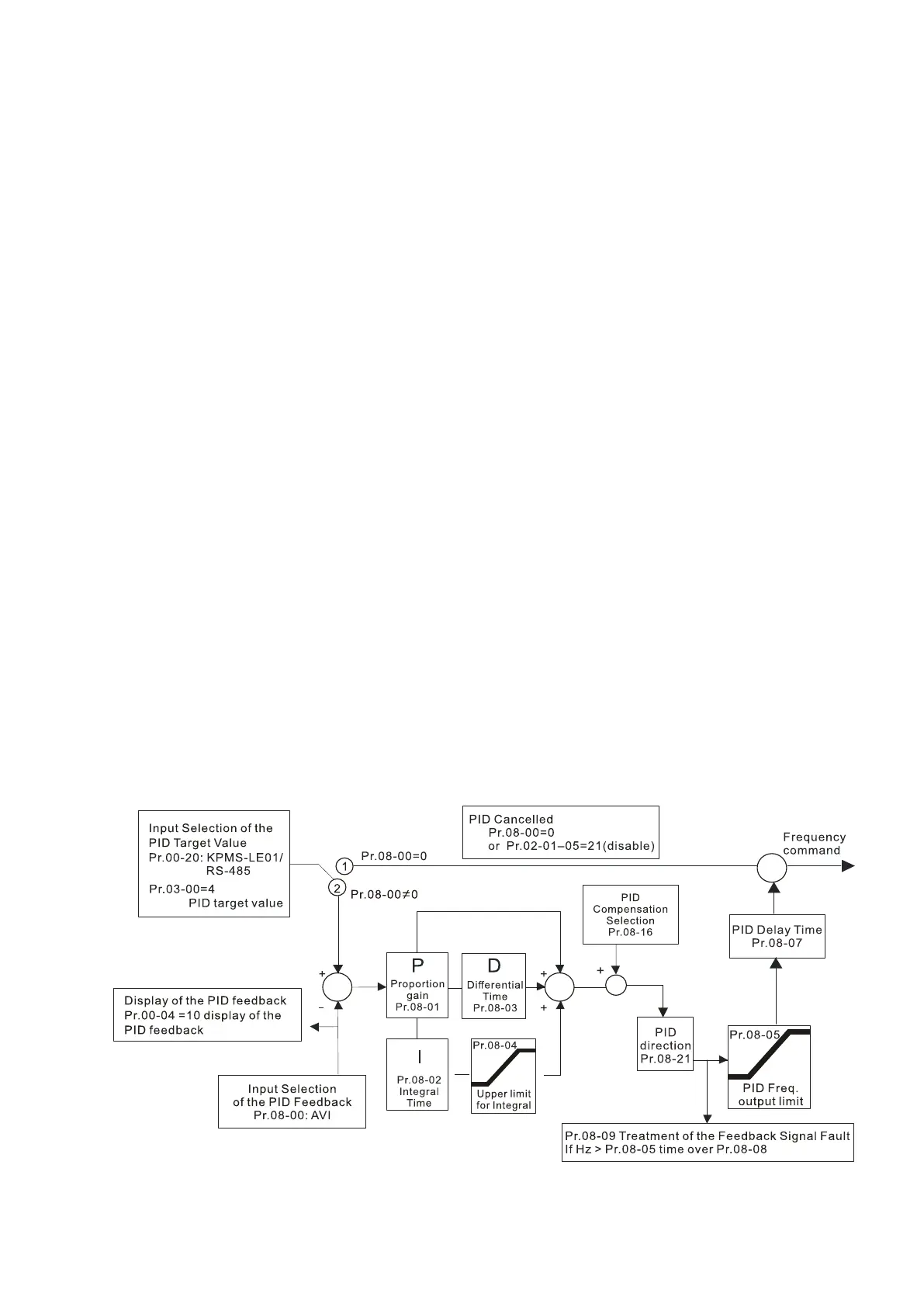

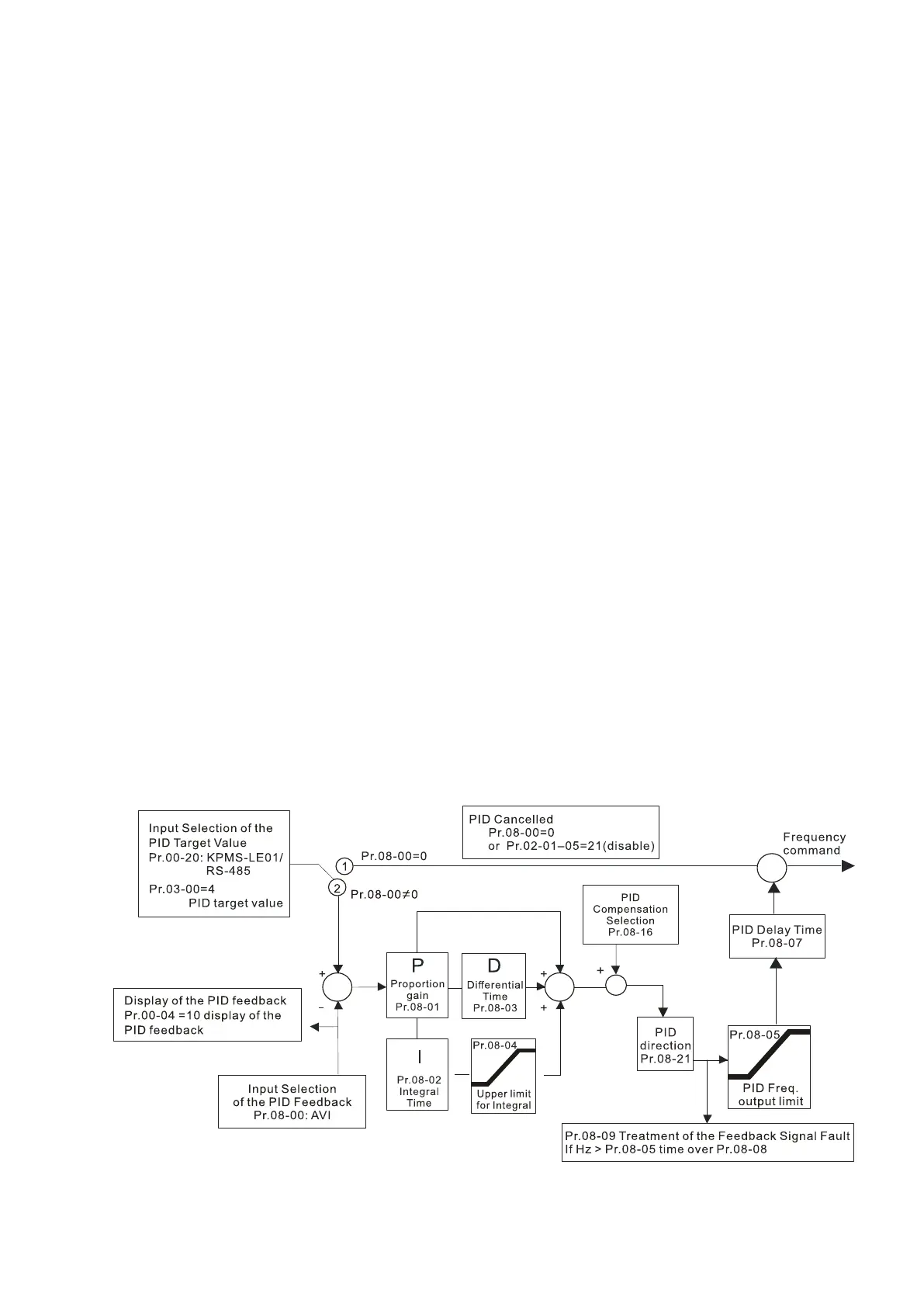

Pr.08-07 determines the primary low pass filter time when in PID control. Setting a large time

constant may slow down the drive’s response rate.

PID control output frequency is filtered with a primary low pass function. This function can filter a

mix of frequencies. A long primary low pass time means the filter degree is high and a short

primary low pass time means the filter degree is low.

Inappropriate delay time setting may cause system error.

PI Control:

Controlled only by the P action, so the deviation cannot be entirely eliminated. In general, to

eliminate residual deviations, use the P + I control. When you use the PI control, it eliminates the

deviation caused by the targeted value changes and the constant external interferences. However,

if the I action is too powerful, it delays the response when there is rapid variation. You can use the

P action by itself to control the loading system with the integral components.

PD Control:

When deviation occurs, the system immediately generates an operation load that is greater than

the load generated only by the D action to restrain the deviation increment. If the deviation is small,

the effectiveness of the P action decreases as well. The control objects include applications with

integral component loads, which are controlled by the P action only. Sometimes, if the integral

component is functioning, the whole system may vibrate. In this case, use the PD control to reduce

the P action’s vibration and stabilize the system. In other words, this control is useful with no brake

function’s loading over the processes.

PID Control:

Use the I action to eliminate the deviation and the D action to reduce vibration; then combine this

with the P action for the PID control. Use the PID method for a control process with no deviations,

high accuracy, and a stable system.

Serial connection

Loading...

Loading...