Chapter 12 Description of Parameter Settings

MH300

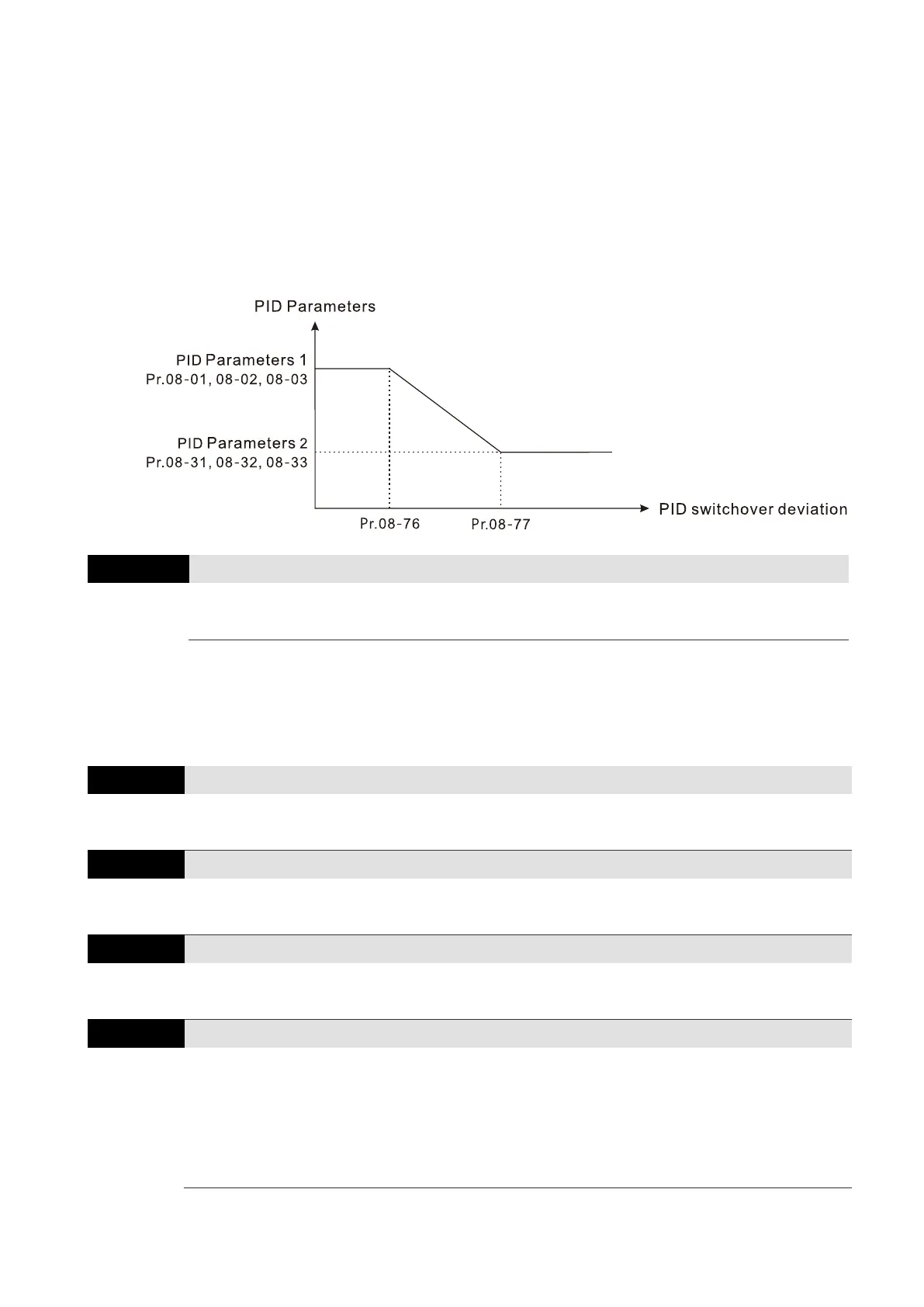

Switch according to the deviation:

When the deviation absolute value between the set point and feedback is smaller than

Pr.08-76 (PID2 Parameter Switch Deviation 1), the first group PID parameters are used.

When the deviation absolute value between the set point and feedback is larger than Pr.08-

77 (PID2 Parameter Switch Deviation 2), the second group PID parameters are used.

When the deviation absolute value between the set point and feedback is between Pr.08-

76 and Pr.08-77, the PID parameter is the linear interpolation value between the two PID

parameter groups.

Allowed reverse running time after start-up

Default: 0.0

Settings 0.0–6553.5 sec.

When Pr.08-78 is not set to 0, allowed reverse running time after start-up is enabled.

When it set to 1

second, the PID control is not allowed to change the running direction within 0–

1 seconds of starting time (Pr.08-21 = 0), and is allowed to change after 1 second of starting time

(Pr.08-21 = 1).

WireBreak detected upper level

Default: 0

Settings 0–100%

WireBreak detected lower level

Default: 0

Settings 0–100%

Default: 0.000

Settings 0.000–65.535 sec.

Default: 0

Settings 0: Warn and do not stop

1: ramp to stop

2: coast to stop

3: Warn, PID hold

Since the tension control may be activated during unwinding, there must be a mechanism to

determine the material cutoff after rewind.

Loading...

Loading...