Chapter 12 Description of Parameter SettingsMH300

12.1-13-8

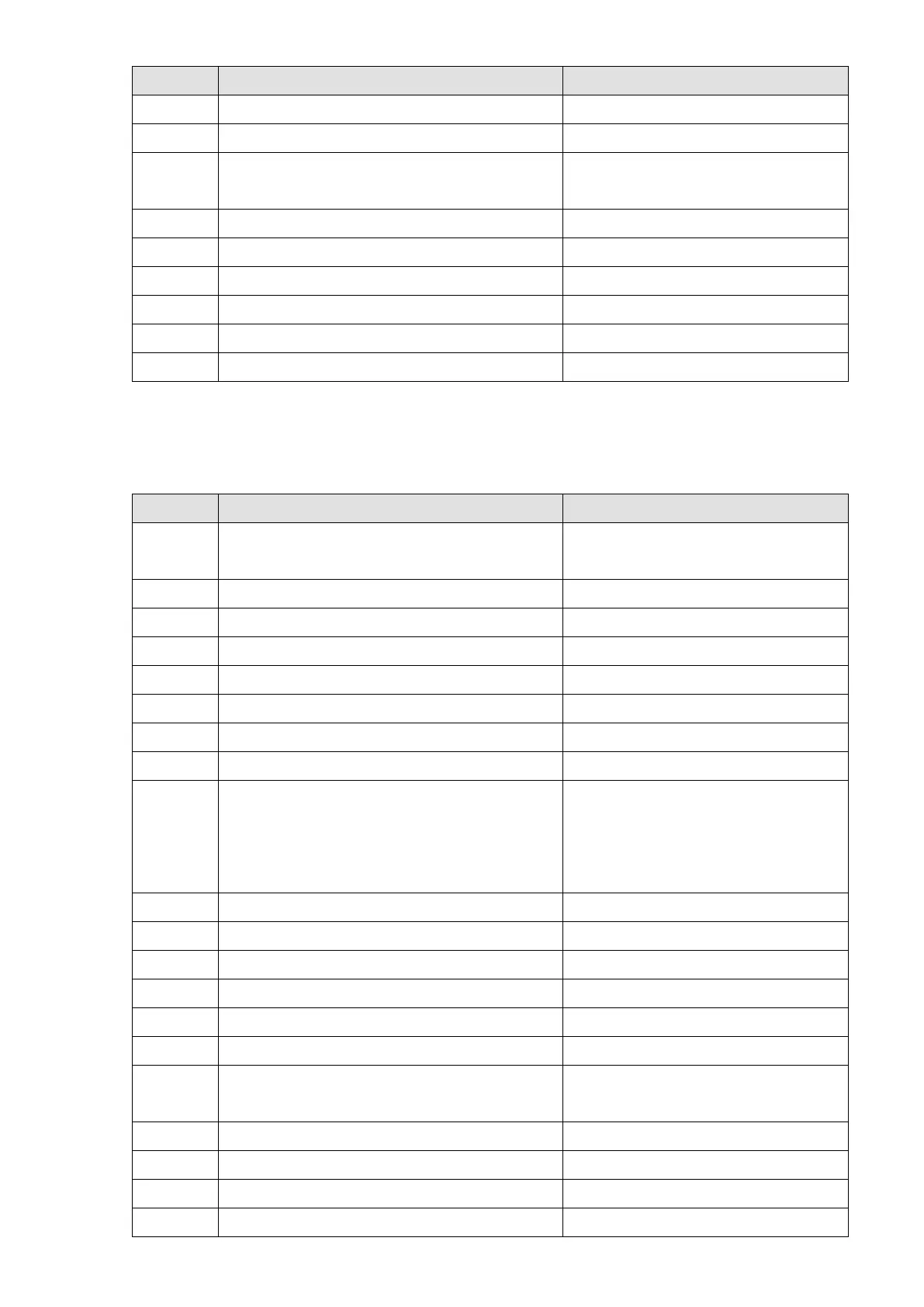

Pr. Parameter Name Settings

03-65 AVI voltage mid-point 9.99

03-66 AVI voltage proportional mid-point 100%

08-00 Terminal selection of PID feedback

1 (Negative PID feedback: by analog

input (Pr.03-00))

08-01 Terminal selection of PID feedback 10

08-02 Integral time (I) 1

08-20 PID mode selection 1 (Parallel connection)

08-21 Enable PID to change the operation direction 0 (Operating direction can be changed)

08-65 Source of PID target value 1 (From Pr.08-66)

08-66 PID target value setting 50%

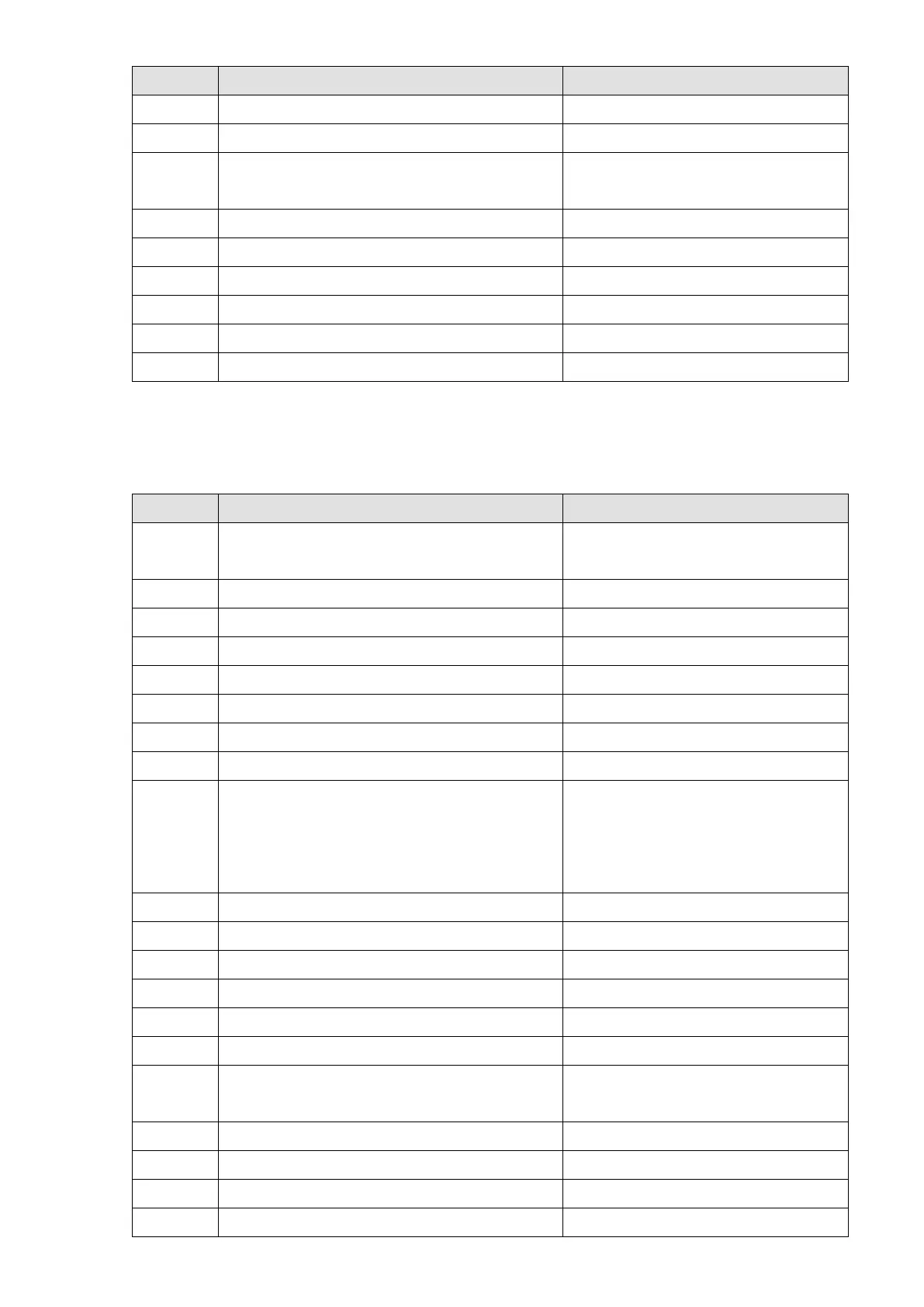

Group setting 12: Tension PID and master / auxiliary frequency function

The following table lists the tension PID and master / auxiliary frequency function setting

application related parameters.

Pr. Parameter Name Settings

00-20

Master frequency command source

(AUTO, REMOTE)

9 (PID function)

00-21 Operation command source (AUTO, REMOTE) 1 (External terminals)

01-00 Motor 1 maximum operation frequency Default setting

01-12 Acceleration time 1 3 (s)

01-13 Deceleration time 1 3 (s)

00-35 Auxiliary frequency source 3 (Inputs from analog input)

03-00 AVI analog input selection 5 (PID feedback signal)

03-01 ACI analog input selection 12 (Auxiliary frequency input)

03-10

Reverse setting when analog signal input is

negative frequency

0 (Negative frequency input is not

allowed. The digital keypad or

external terminal controls the

forward and reverse direction. )

03-12 ACI analog input gain 100.0%

03-29 ACI terminal input selection 1 (0–10 V)

03-50 Analog input curve selection 1 (Three-point curve of AVI)

03-63 AVI voltage lowest point 0.00

03-65 AVI voltage mid-point 9.99

03-66 AVI voltage proportional mid-point 100%

08-00 Terminal selection of PID feedback

1 (Negative PID feedback: by analog

input (Pr.03-00))

08-01 Terminal selection of PID feedback 10

08-02 Integral time (I) 1

08-20 PID mode selection 1 (Parallel connection)

08-21 Enable PID to change the operation direction 0 (Operating direction can be changed)

Loading...

Loading...