9.10.1 Normal speed

The full speed sengs for the booster and dry pump are set by us when the pump is

manufactured. If a lower full speed is required then this can be set using a downloadable

conguraon. Conguraons can be downloaded using our Conguraon Download

Ulity (CDU). Please contact our applicaon specialists to discuss your requirements.

By default, dry pump and booster speed control are set to normal, meaning that the

pumps will run at their congured full speeds.

9.10.2 External voltage

The auxiliary gauge input on the rear of the system (available as an oponal accessory,

shown in Figure: The controls/connectors on the rear of the pump (system with rear

exhaust and castors/levelling feet ed), item 14) can be used as a 0-10 V speed control

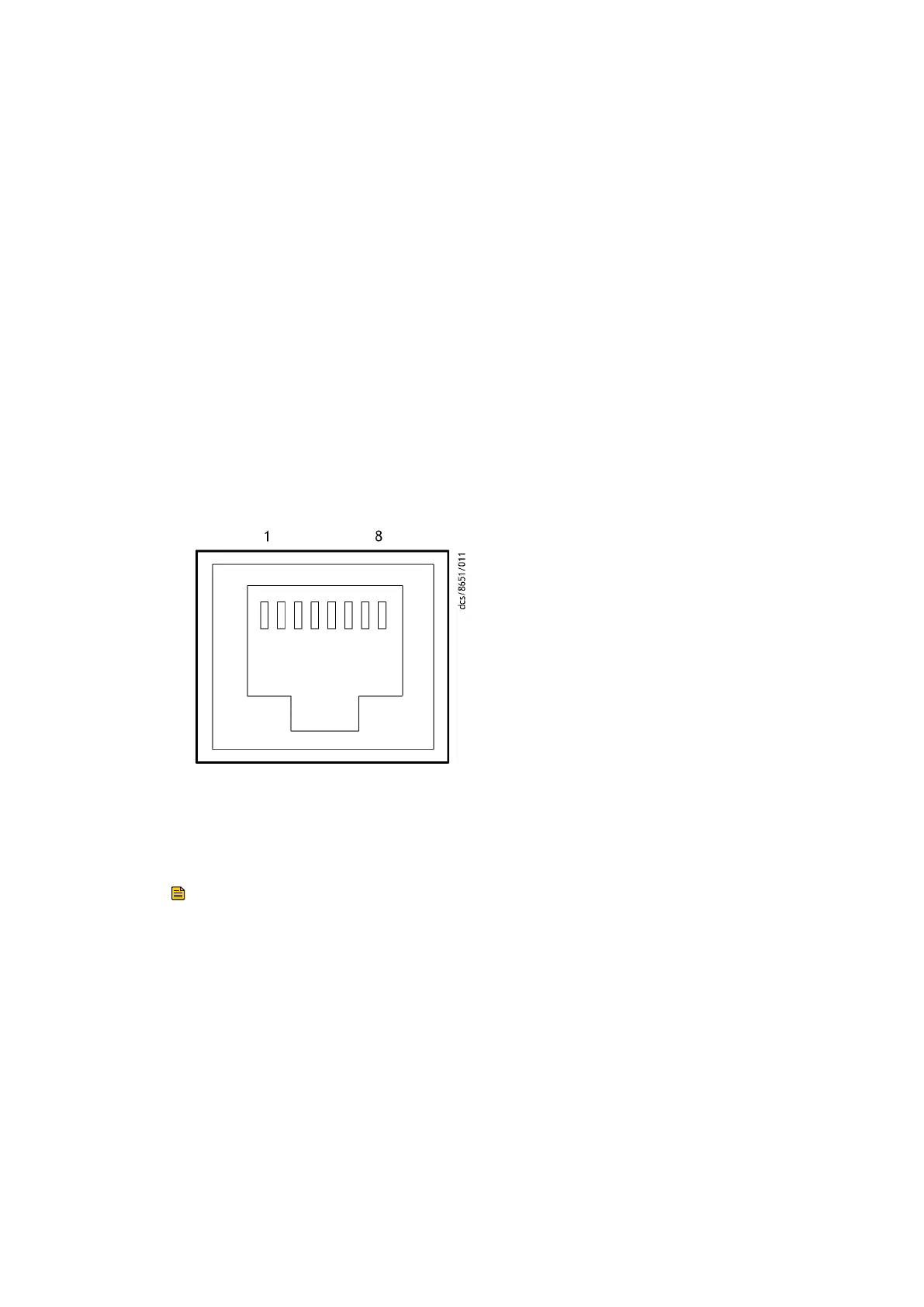

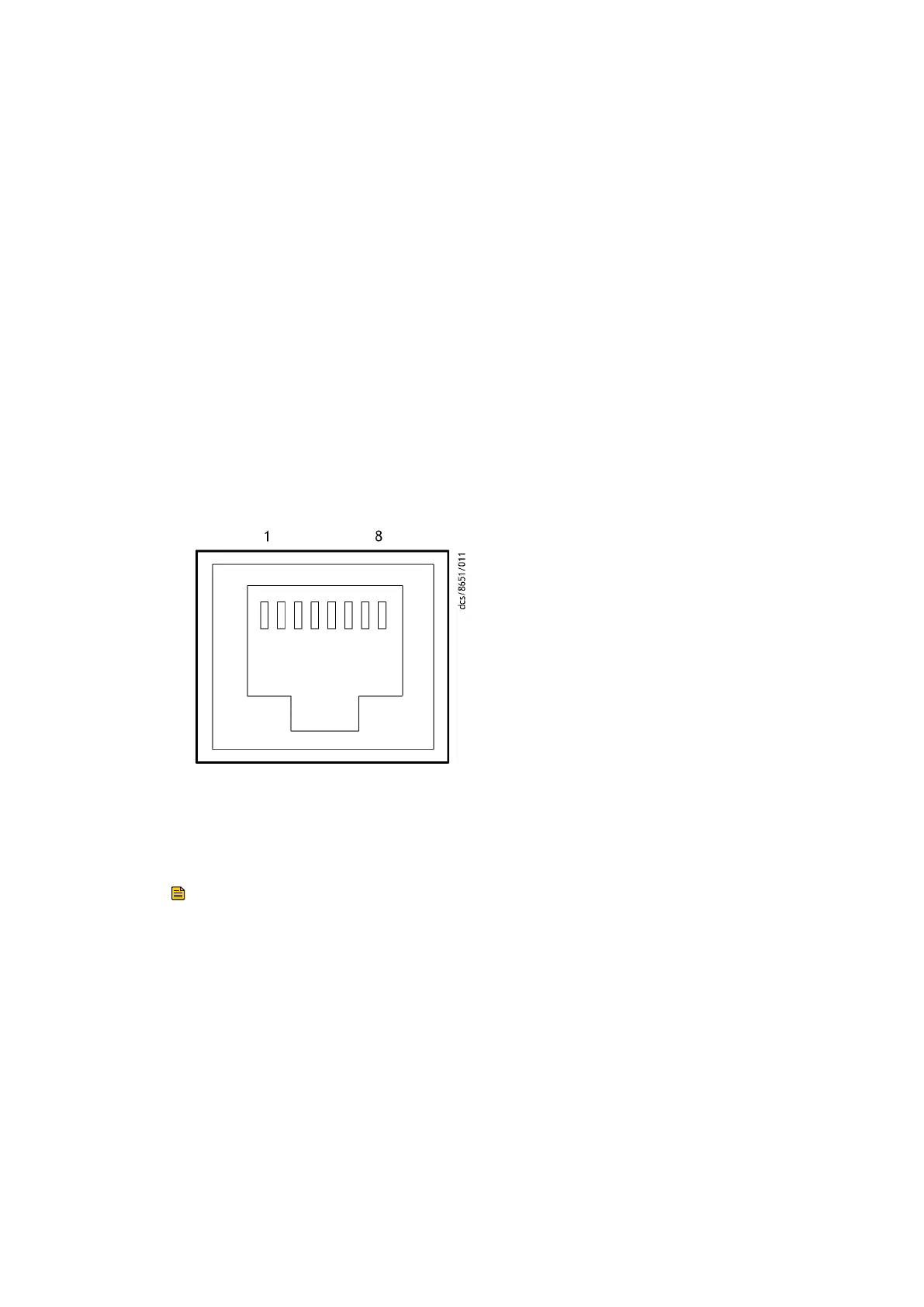

for either the dry pump or the booster. The connector is a standard RJ45 (refer to Figure:

Pin numbers on the auxiliary gauge interface) to idenfy the pin numbers. Use the pin 3

for the external voltage signal and pin 5 for signal common.

Figure 66 Pin numbers on the auxiliary gauge interface

The 0-10 V input is scaled linearly and may be congured such that the pump runs at

100% speed when the input voltage is either 0 V or 10 V. The pump speed may be

decreased to 20 Hz by increasing/decreasing the supply voltage depending on the

external voltage speed control conguraon.

Note:

If the cable becomes disconnected, the pump will run at full speed.

To enable the external voltage as the speed control source, use the PDT to select the

external voltage for the appropriate pump.

9.10.3 SIM protocol

It is possible to independently control the speed of both the dry pump and the booster

using the built-in SIM protocol. Refer to the SIM Protocol Manual (P411-00-200) for

details of the commands to use.

The system supports the SIM protocol by both the Ethernet and the serial ports. Refer to

How to set up the Ethernet port on page 151 for informaon about seng up the

Page 146

M58800880_H - Pump display terminal

Loading...

Loading...