3. Keep adding oil unl the oil level is in line with the MAX indicator.

4. Ret the oil ll plug.

5. Ret all dry pumping system side panels.

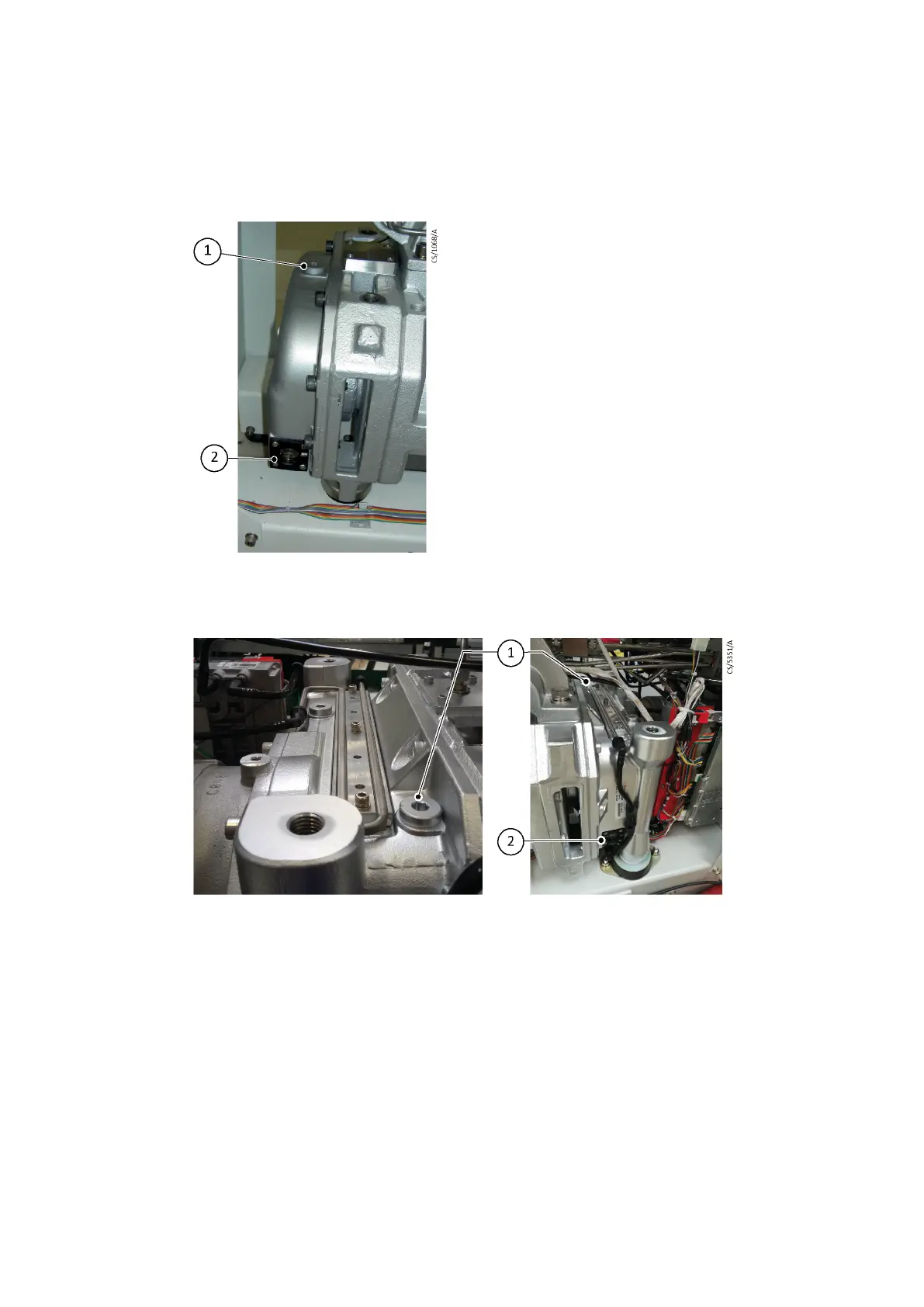

Figure 14 Locaon of the oil sight glass and the ll plug on end cover

1. Oil ller plug 2. Oil sight glass1. Oil ller plug 2. Oil sight glass

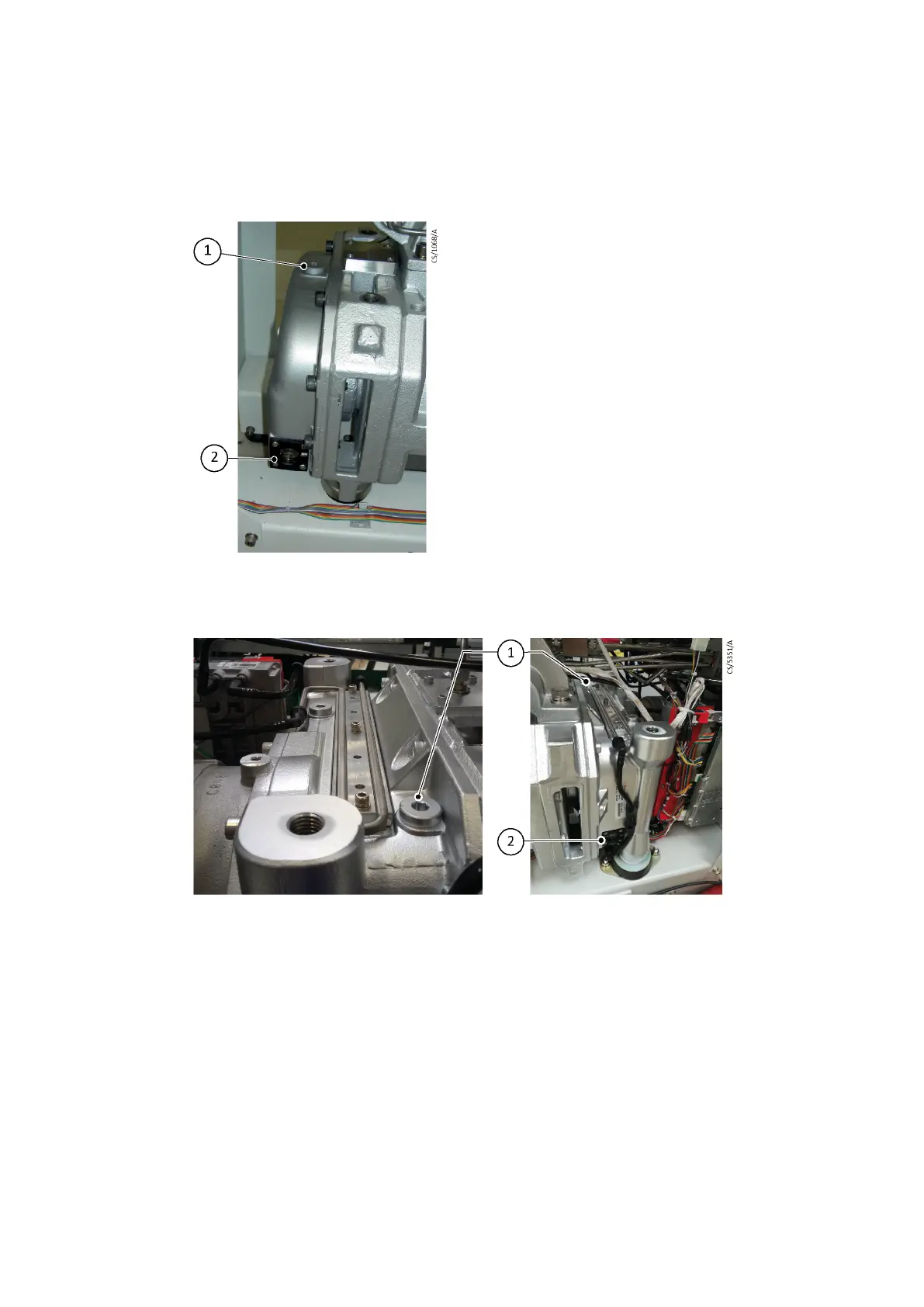

Figure 15 Locaon of the oil sight glass and the ll plug on gearbox

1. Oil ller plug 2. Oil sight glass1. Oil ller plug 2. Oil sight glass

If the oil is very old or has light contaminaon then it is possible to replace the oil,

contact us for more informaon.

5.4.2 Inspect the connecons, pipelines, cables and ngs

Depending on the applicaon, inspecon and cleaning of the exhaust pipe and any

elbows or check valves ed may be needed. Contact us for details and training. If the

dry pumping system is not relocated for maintenance, ensure that all supplies are locked

out and tagged out before starng the following procedure.

1.

Remove the enclosure side and top panels.

Page 72

M58800880_H - Maintenance

Loading...

Loading...