Refer to Figure: Front panel controls. To enable the Green mode/standby mode when

the pump is running and warmed up, press and hold the start buon (item 3) for 5

seconds. The pump green mode LED (item 10) will illuminate connuously. The pump

running LED (item 2) will ash.

To disable Green mode/standby mode, and therefore to enable the on‑process mode,

press and hold the start buon (item 3) for 5 seconds. If the pump has warmed up, the

pump green mode LED (item 10) will go out and the pump running LED (item 2) will

illuminate connuously. If the pump has not warmed up, both the Green mode LED and

the pump running LED will ash unl the pump is fully warm. The Green mode LED will

then go out and the running LED will illuminate connuously to indicate that the pump is

now on‑process.

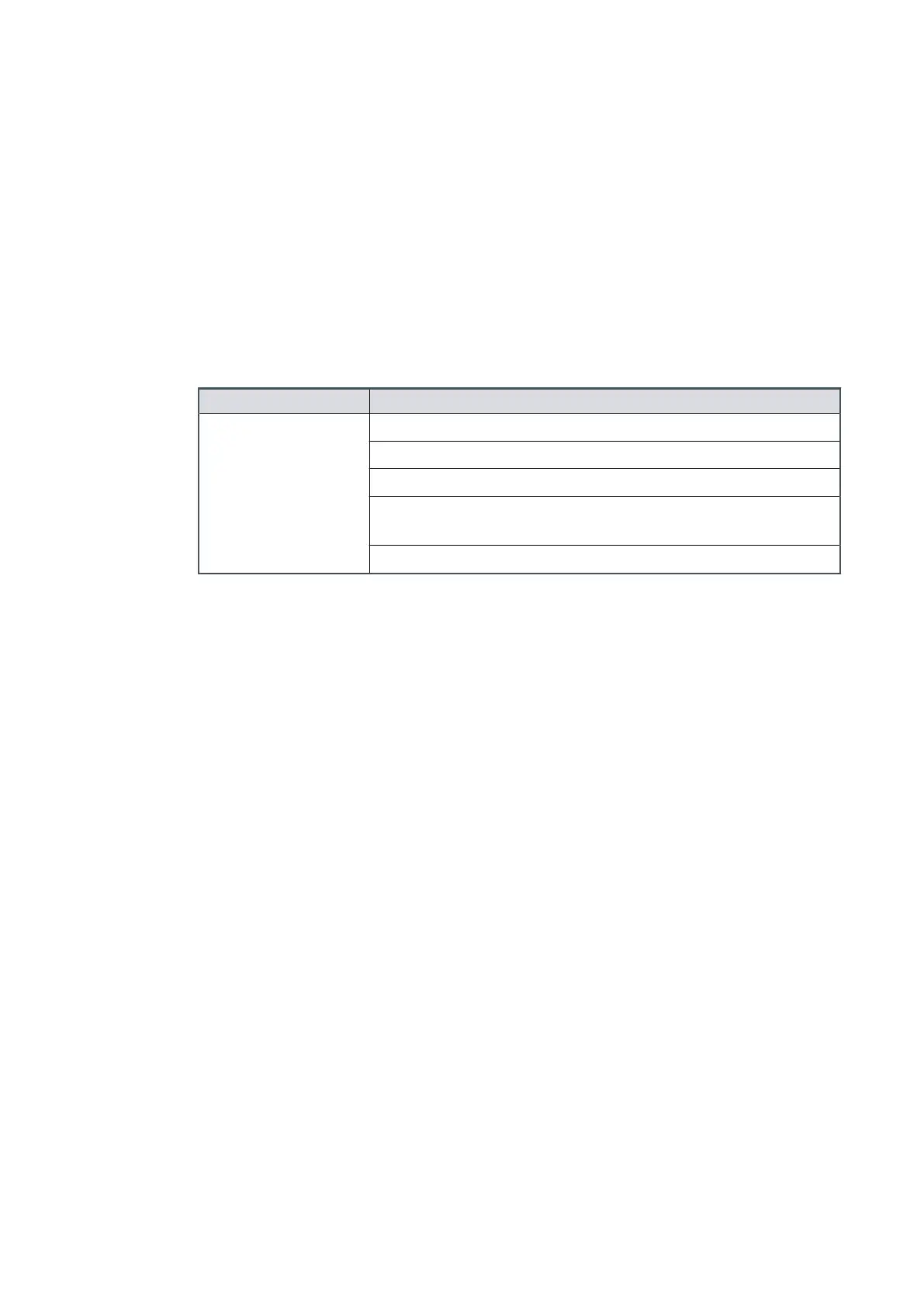

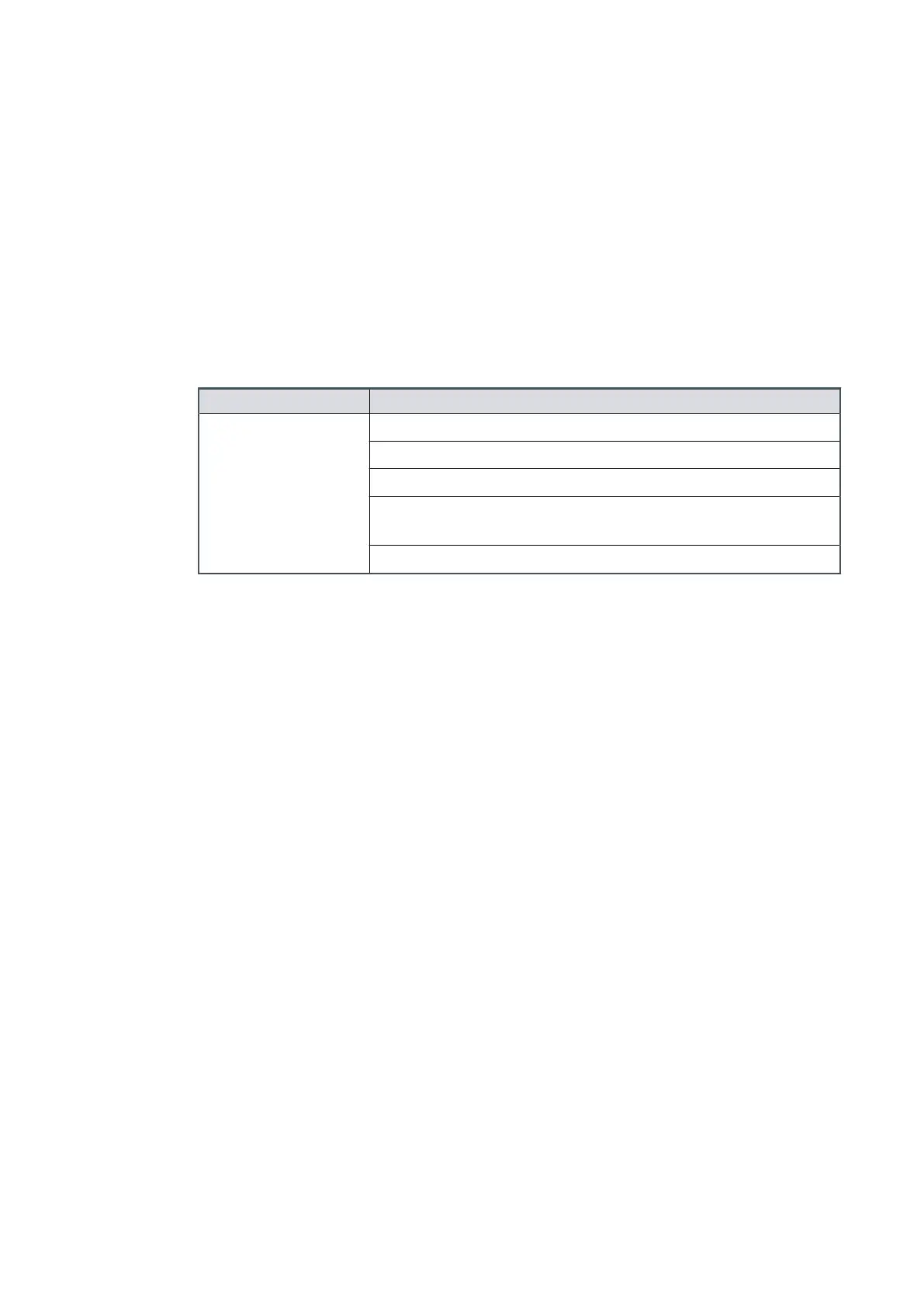

Table 21

Green mode/standby sequence

Sequence Descripon

Green mode/Standby Inlet isolaon valve is closed (if ed).

Pump runs at standby (Green mode) speed.

Gas ballast valve is closed (medium‑duty pumps only).

If the pump temperature drops below working temperature

then it will start to warm up again.

Pump ready line will be o if pump is not warmed up.

The dry pumping system can also be set into Green mode/standby mode using the

following methods:

▪ PDT, by the commands menu. Refer to Commands menu on page 124.

▪ MCM MicroTIM. Refer to the MicroTIM manual D37360880.

▪

By commands sent over the serial interface using the SIM protocol. Refer to the

SIM Manual P41100200, or using the E54 protocol.

4.4 Pumping Argon

Due to its inert nature, Argon is commonly used in the heat treatment and other

metallurgical applicaons, especially at high temperatures. The thermodynamic

properes of Argon can give challenges and dicules when it comes to the vacuum

pumping systems. The inherent thermal properes of Argon including its ineciency to

transfer heat away to the cooling system which, if not controlled, can cause the

problems for dry vacuum pumps. If heat is not successfully removed from the rotors, a

dierenal thermal expansion can cause seizures.

The GXS160, GXS250 and GXS450 (with or without booster) can pump Argon with no

restricons.

The GXS750, GXS750/2600 or GXS750/4200 is capable of pumping Argon but not

connuously at all pressures. At 110 Hz, the connuous operang range is restricted to

less than 20 mbar at the inlet to screw pump (this is equivalent to 10 mbar at the inlet to

booster). To extend the connuous operang range up to 500 mbar and to enable the

pump down of the large chambers, the operang speed of the pump must be reduced to

80 Hz. This is valid with Argon at ambient temperature.

Page 58

M58800880_H - Operaon

Loading...

Loading...