4.5.3 Front panel control operaon

Press and hold the stop buon (Figure: Front panel controls, item 4) for 5 seconds to

stop the pump in Auto shut down mode (recommended). Repeat within 10 seconds to

stop the pump in the Fast shut down mode. The running LED (Figure: Front panel

controls, item 2) ashes while the pump is slowing down and will then turn o when the

pump has shut down.

4.6 Automac shut down

Normally, if an alarm condion exists, the control system will shut down the dry

pumping system. When the dry pumping system shuts down, all the purge gas valves

close and the pump stops. For the dry pumping systems containing a dry pump and

booster combinaon, some alarms will cause only the booster to stop, and not the full

dry pumping system.

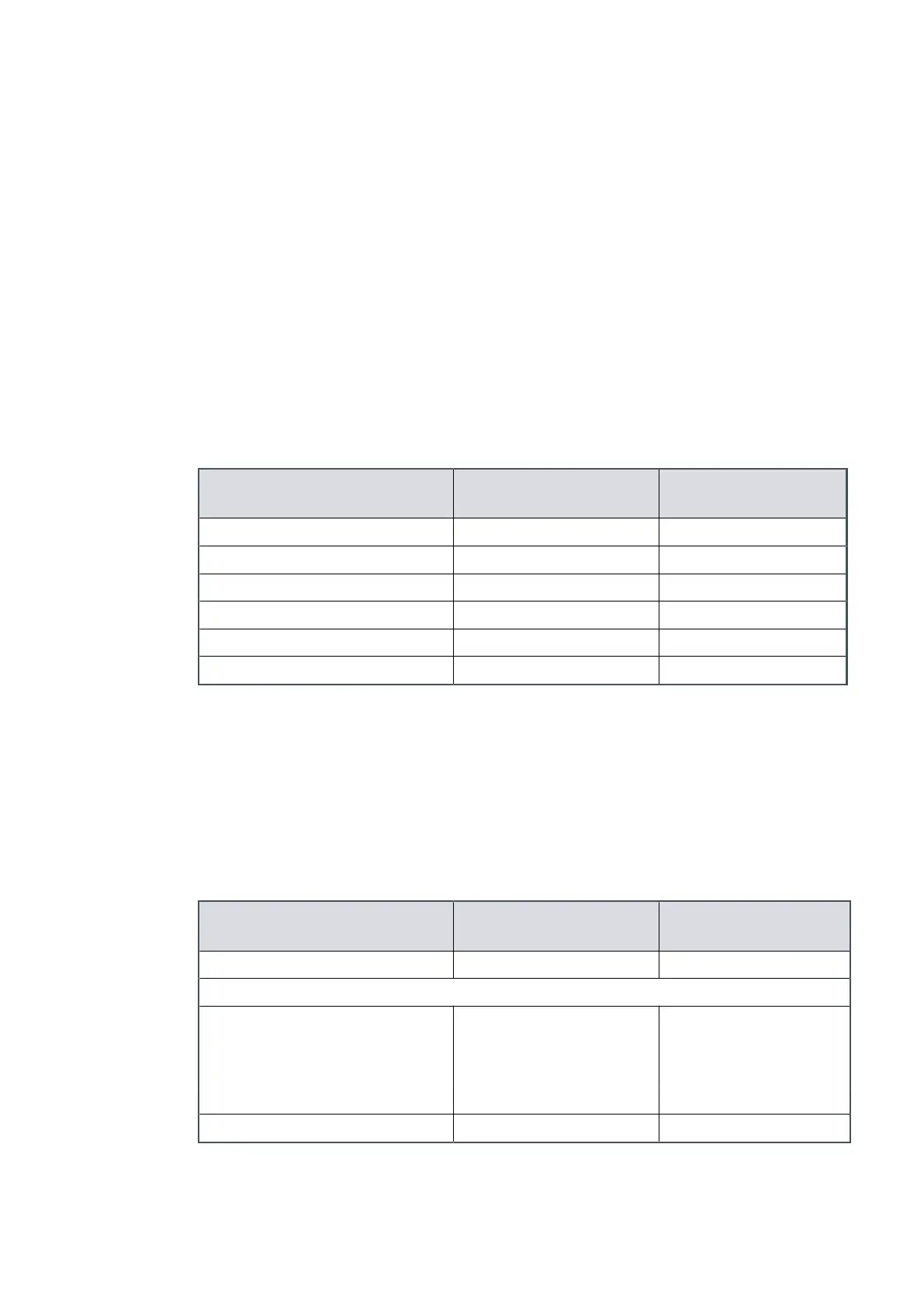

Table 23

Alarm acons

Alarm descripon

Alarm stops the dry pump

Alarm stops the booster

pump

EMS or system conguraon fault Yes Yes

Exhaust pressure* Yes Yes

Booster stator temperature† No Yes

Dry pump stator temperature Yes Yes

Booster status† No Yes

Dry pump status Yes Yes

* Not applicable to systems with light

‑

duty gas module.

† Not applicable to systems which do not contain a booster.

4.7 Unplanned shut down and alarms

The dry pumping system is ed with a number of pump protecon sensors that will

give warnings and alarms. Refer to Table: Pump protecon sensors.

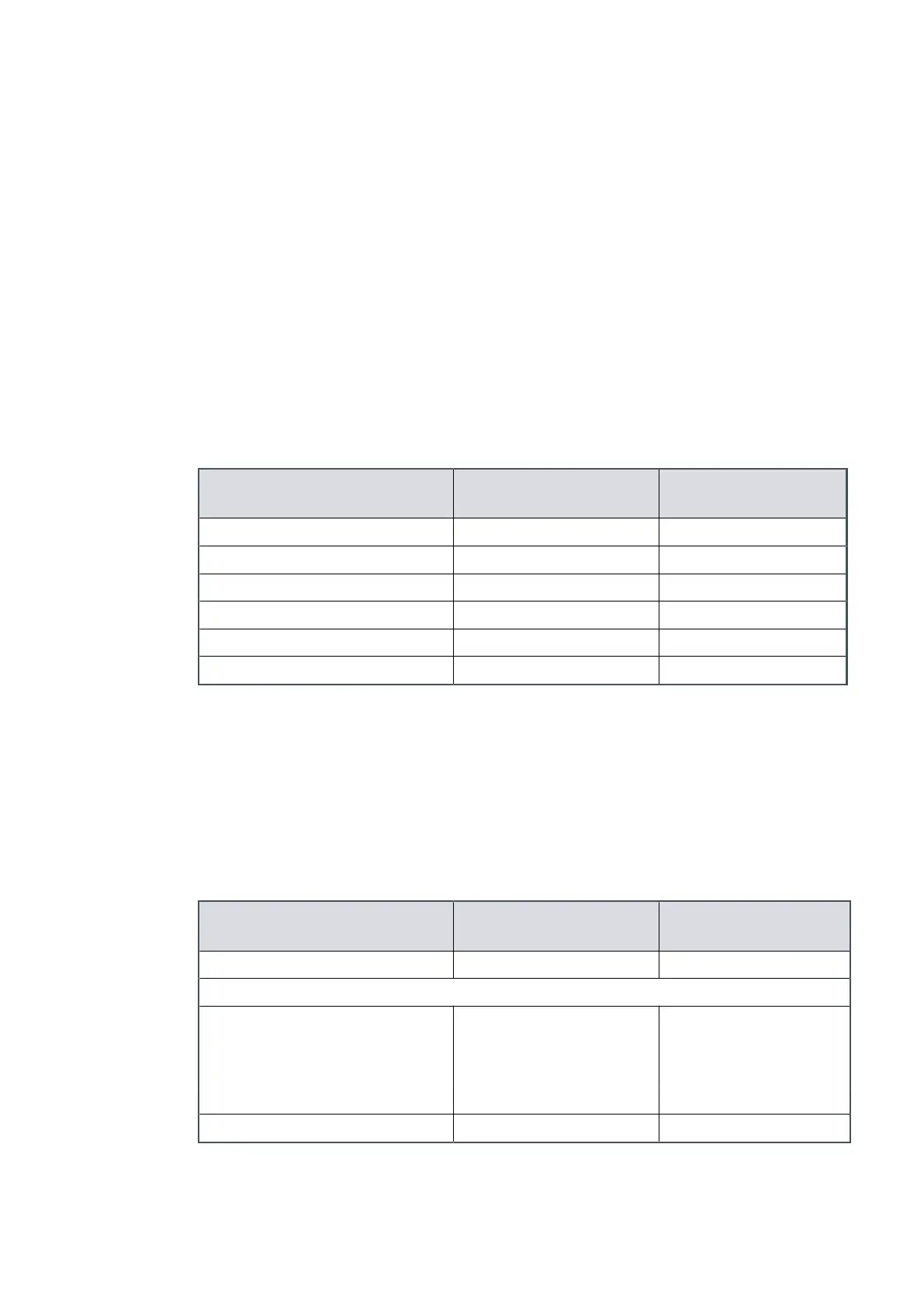

Table 24

Pump protecon sensors

Sensor

Warning condion

triggered

Alarm condion

triggered

Exhaust pressure transducer* 0.3 barg (4.4 psig) 0.4 barg (5.8 psig)

DP TEMP temperature

GXS160 and GXS160/1750 150 °C 160 °C

GXS250 and GXS250/2600 150 °C 165 °C

All GXS450 dry pumping systems 170 °C 180 °C

All GXS750 dry pumping systems 180 °C 190 °C

MB stator temperature 120 °C 130 °C

* Not available on the dry pumping systems with the light

‑

duty gas module.

Page 61

M58800880_H - Operaon

Loading...

Loading...