Part 1: Setup & Operation 8. Motion Range and Robot Coordinates

47

(1) Exit EPSON RC+, shut down the SPEL Runtime Drivers, and turn OFF the Drive

Unit.

(1) Exit SPEL 95, and turn OFF the Drive Unit.

(1) Turn OFF the controller.

(2) Screw a hexagon socket head cap bolt into each of the holes corresponding to the

angle setting.

Joint Series

Hexagon socket head cap

bolt (fully threaded)

Number

of bolts

Recommended tightening

torque

ES M8×10 3720N⋅cm (380kgf⋅cm)

#1

EL M12×20 12740N⋅cm (1300kgf⋅cm)

#2 ES/EL M8×10

1/side

3720N⋅cm (380kgf⋅cm)

Threaded hole locations corresponding to the angle setting are shown below.

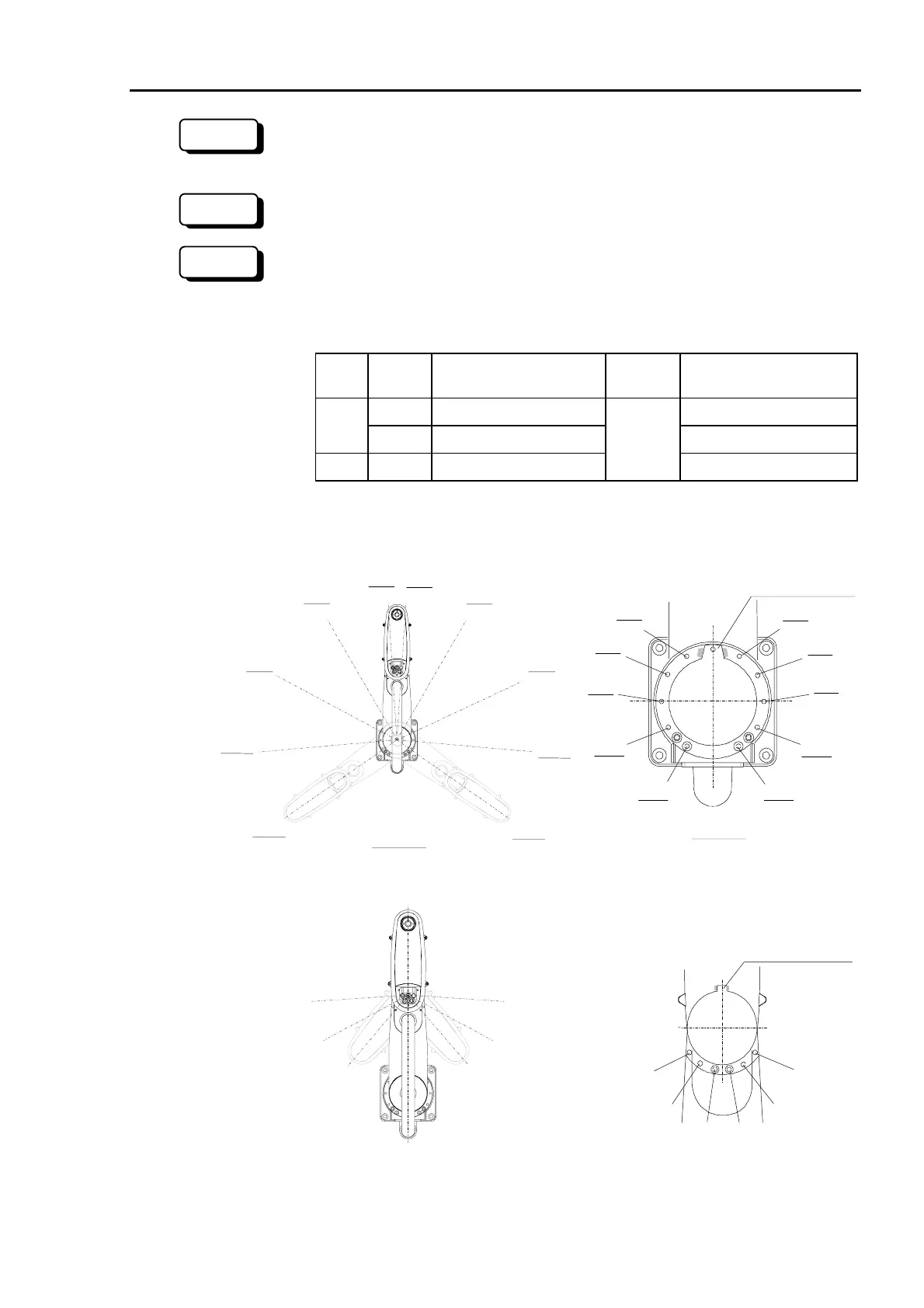

Joint #1

EL series

ES series

+35

°

+40

°

+65

°

+70

°

+95

°

+100

°

+125

°

+130

°

-

35

°

-

40

°

-

65

°

-

70

°

-

95

°

-

100

°

+125

°

+130

°

+5

°

+10

°

-

5

°

-

10

°

EL series

ES series

Mechanical stop for

joint #1

+5

+10

-

5

-

10

+35

+40

-

35

-

40

+65

+70

-

65

-

70

+95

+100

-

95

-

100

+125

+130

-

125

-

130

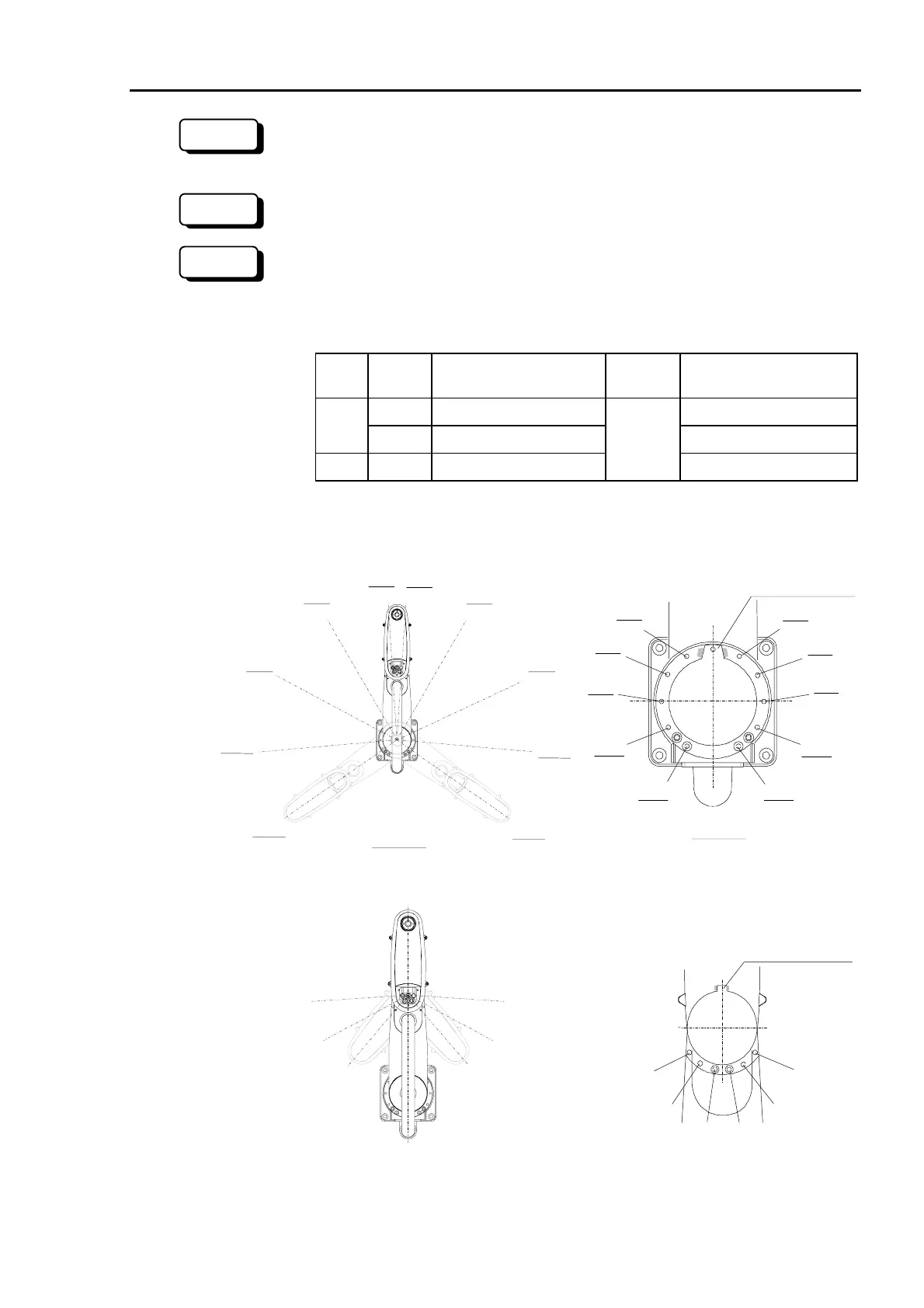

Joint #2

-

95

°

+95

°

-

120

°

-

140

°

+140

°

+120

°

Mechanical stop for

joint #2

-

95 +95

-

120

-

140 +140

+120

Figure 29. Threaded holes for changing the position of mechanical stops

300

RC+

SPEL 95

Loading...

Loading...