EPSON WF-C5790/WF-C5790a/WF-C5710/ET-8700/WF-C5210/WF-C5290/WF-C5290a Revision A

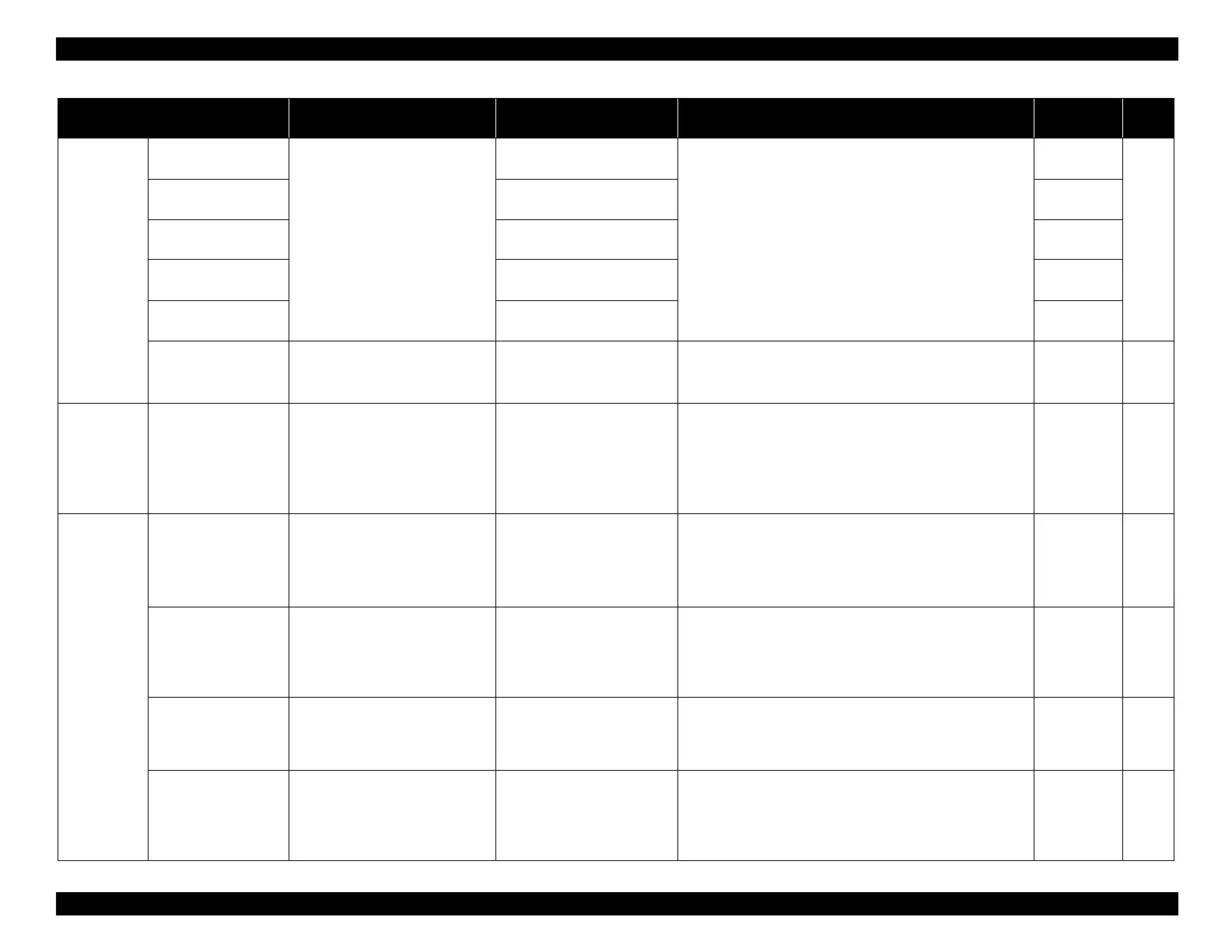

Adjustment Adjustment and Inspection Overview 554

Confidential

Adjustment

(Mechanical)

CR motor heat

protection control

Measure product variations to set

the appropriate correction values.

Also, make a pass/fail judgment by

calculating whether or not the

operation load is within the

expected range from the motor

current value.

-

Automatically measure the correction value and perform the

operation load check by selecting “XX heat protection control”

from the Adjustment Program menu and executing the item.

Adjustment

Program

P. 567

PF motor heat

protection control

-

Adjustment

Program

IS motor heat protection

control

-

Adjustment

Program

ASF motor heat

protection control

-

Adjustment

Program

Scanner/ADF motor heat

protection control

-

Adjustment

Program

PE Sensor Check

To detect PE Detector part failure or

assembly failure.

Paper type: Plain paper

Size: A4

Paper source: Paper cassette (1)

Select

“

PE Sensor Check

”

from the Adjustment Program menu and

execute, and run plain paper through. After the operation has

completed, obtain the data, and measure chattering frequency and time.

Adjustment

Program

P. 567

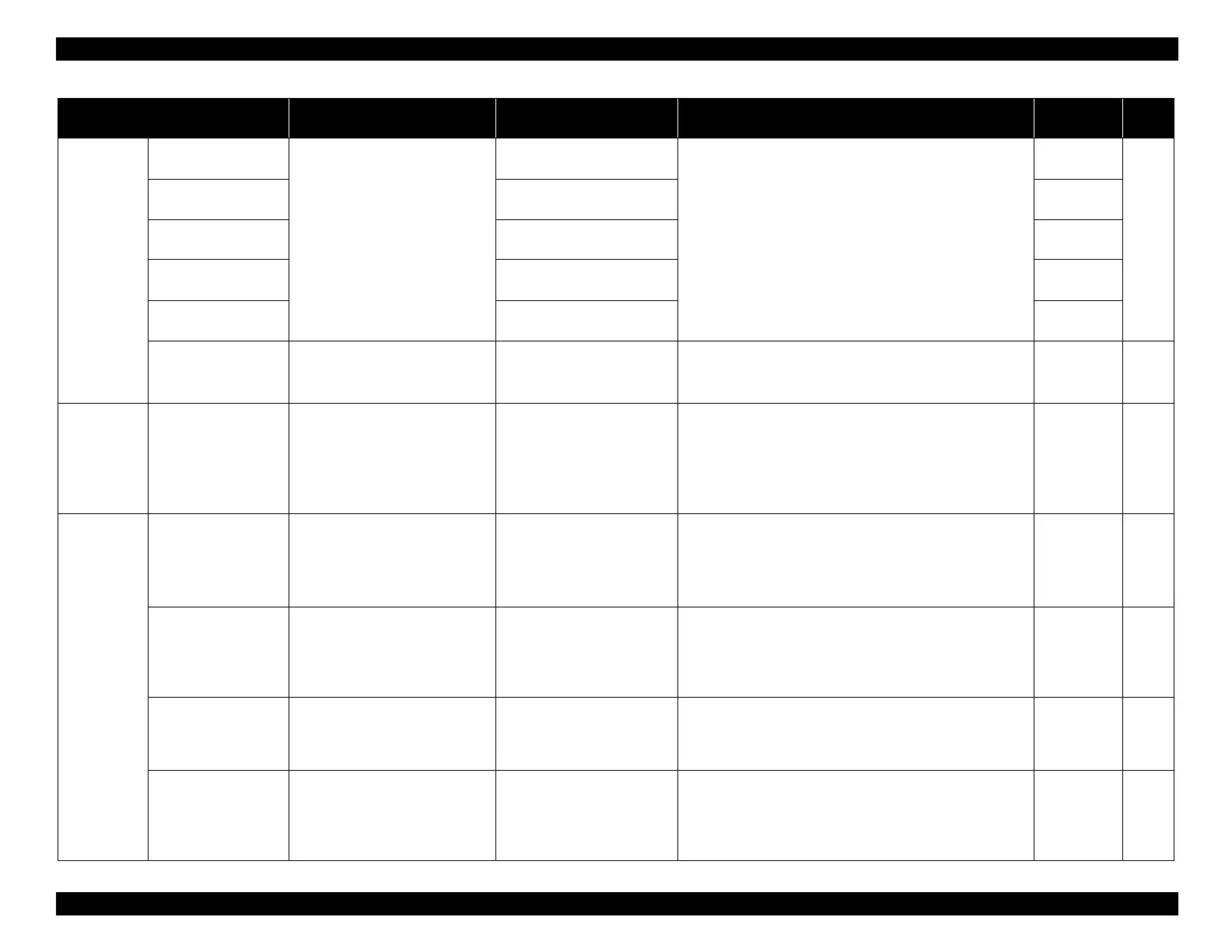

Adjustment

(Print adjustment

by mechanical)

Head angular mecha

adjustment

Use software to correct the vertical/

horizontal tilt occurs when installing

the head.

Paper type: Photo matte paper

Size: A4

Paper source: Rear ASF Assy

Select “Head angular Adjustment Mech” from the menu of the

adjustment program and execute the item to print the

adjustment pattern.

Determine the adjustment value from the adjustment pattern

based on the judgment criteria and then perform adjustment by

turning the adjustment dial provided on the CR unit.

Adjustment

Program

P. 568

Adjustment

(Print adjustment

by program)

PTS delay adjustment

Correct the impact offset caused by

a difference in the speed of the

lowspeed part and acceleration/

deceleration part of the CR.

Paper type: Plain paper

Size: A4

Paper source: Paper cassette (1)

Select “PTS delay adjustment” from the Adjustment Program

and execute the item to print the adjustment pattern.

Determine the adjustment value from the adjustment pattern

based on the judgment criteria and then enter the adjustment

value from the PTS delay adjustment menu.

Adjustment

Program

P. 572

Head angular

adjustment

Use software to correct the vertical

or horizontal tilting that occurs at

the time of print attachment.

Paper type: Plain paper

Size: A4

Paper source: Paper cassette (1)

Select “Head angular adjustment” from the Adjustment

Program and execute the item to print the adjustment pattern.

Determine the adjustment value from the adjustment pattern

based on the judgment criteria and then enter the adjustment

value from the Head angular adjustment menu.

Adjustment

Program

P. 573

Bi-d adjustment

Use software to correct the print

timing for aligning the print position

between the outward path and return

path when bidirectional printing.

Paper type: Plain paper

Size: A4

Paper source: Paper cassette (1)

Select “Bi-d adjustment” from the Adjustment Program and execute

the item to print the adjustment pattern. Determine the adjustment

value from the adjustment pattern based on the judgment criteria

and then enter the adjustment value from the Bi-d adjustment menu.

Adjustment

Program

P. 574

Paper Skew adjustment

Use software to correct the print

timing for aligning the print position

between the outward path and return

path when bidirectional printing in

band feed mode.

Paper type: Plain paper

Size: A4

Paper source: Paper cassette (1)

Select “Paper Skew adjustment” from the Adjustment Program

menu and execute the item to print the adjustment pattern.

Determine the adjustment value from the adjustment pattern

based on the judgment criteria and then enter the adjustment

value from the Paper Skew adjustment menu.

Adjustment

Program

P. 575

Adjustment name Purpose

Adjustment /

inspection paper /feed tray

Adjustment procedure overview Tools

Reference

Loading...

Loading...