使用说明书 Operation Instruction

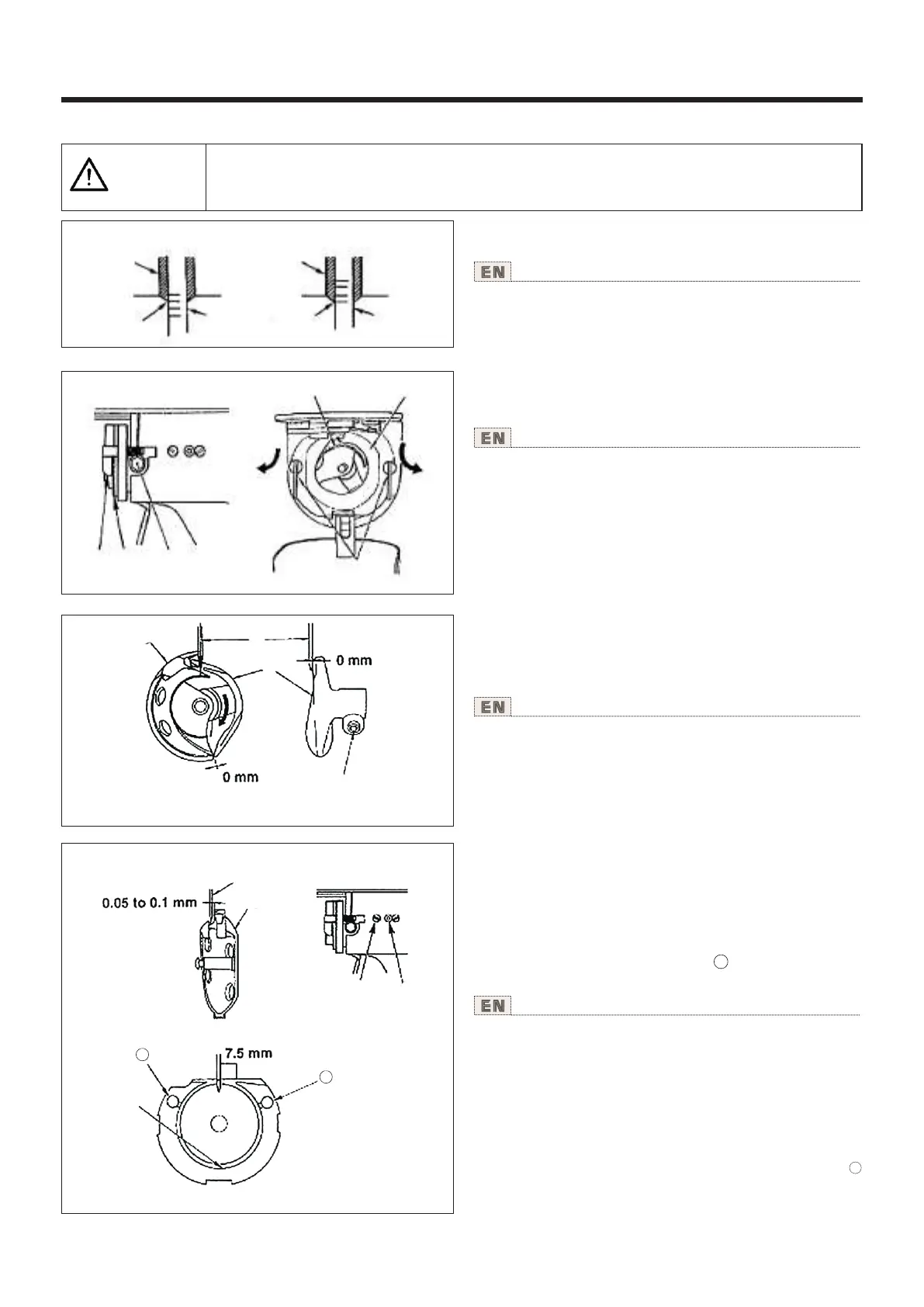

2.机针与旋梭 eedle-to-shuttle relationAdjusting the n

1)用手转动手轮,针杆①上升时,把下刻线②对准

针杆下挡块前端一致。

1) Turn the handwheel by hand. When needle bar ① has gone

up, adjust so that lower marker line ② engraved on the needle

bar aligns with the bottom end of the needle bar bushing ③ ,

lower.

为了防止缝纫机的意外起动,请关掉电源之后进行操作

注意

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

①

③

②

①

③

②

①

③

②

④

③

②

机针 和 刻 线 的 关 系

relation between needle and engraved lines

2) Loosen setscrew ① in the driver. Open inner hook pressers

② to the right and left, and remove inner hook presser ③ .

(NOTE) At this time, be careful not to let inner hook ④ come

off and fall.

2)拧松驱动器固定螺丝①,左右打开中旋梭压片②,

卸下中旋梭压脚③。

(注意)此时请注意不要脱落中旋梭④。

④

①

3)为了让中旋梭④的梭尖与针⑤的中心一致,同时

防止驱动器⑥在前端面与机针相碰,弄弯机针,请把

驱动器前端面与机针的间隙调整为0mm,然后把驱动

器固定螺丝①拧紧。

3) Adjust so that the blade point of inner hook ④ aligns with

the center of needle ⑤. and that a clearance of 0 mm is

provided between the front end of the driver and the needle

as the front end face of driver ⑥ receives the needle to

prevent the needle from being bent. Then tighten setscrow ①

of the driver.

⑤

⑥

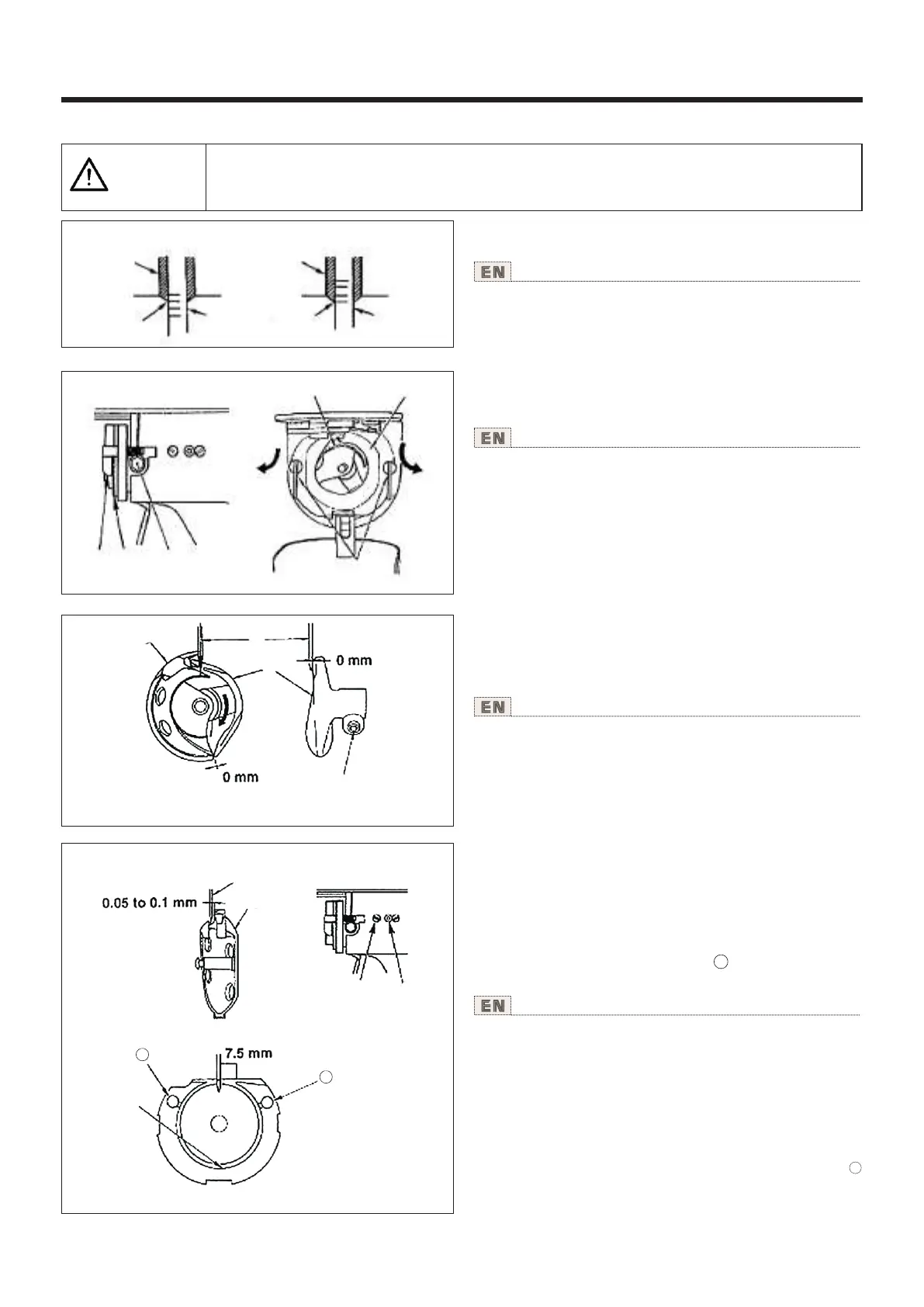

4)拧松大旋梭固定⑦,左右转动大旋梭调节轴⑧,调节

大旋梭的前后位置,把机针⑤和中旋梭④的梭尖的间

隙调整为0.05-0.1mm。

5)调整完大旋梭的前位置后,机针和大旋梭的间隙

应为7.5mm,然后拧紧大旋梭固定螺丝⑦。

(注意)较长时间没有使用缝纫机或清扫过旋梭周围

之后等时,请往轨道部⑨和油芯⑨加少量的机油后再

使用。

4) Loosen setscrew ⑦ of the shuttle,and adjust the longitudinal

position of the shuttle. To do this adjustment, turn shuttle race

adjusting shaft ⑧ clockwise or counterclockwise to provide a

0.05 to 0.1 mm clearance between needle ⑤ and the blade

point of inner hook ④ .

5) After adjusting the longitudinal position of the shuttle,further

adjust to provide a 7.5 mm clearance between the needle and

the shuttle by adjusting the rotaiing direction. Then tighten

setscrew ⑦ of the shuttle.

(NOTE) Apply a small amount of oil to race section ⑨ and oil wick ⑨,

and use the sewing machine after an extended period of disuse or

cleaning the periphery of hook portion.

10

10

⑨

10

⑧

⑤

④

⑦

10

32

Loading...

Loading...