CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 119

9.8 VERIFYING THE GEARING CHAIN TIGHTENING

Authorized Personnel: MECHANICS

a) Open the turret door.

b) Install the standard striker holder without combinable weights or the light striker holder

with all combinable weights on the instrument.

c) Move the striker holder to quota Z=1200 mm using the command “Move to height”

from the “Service” menu.

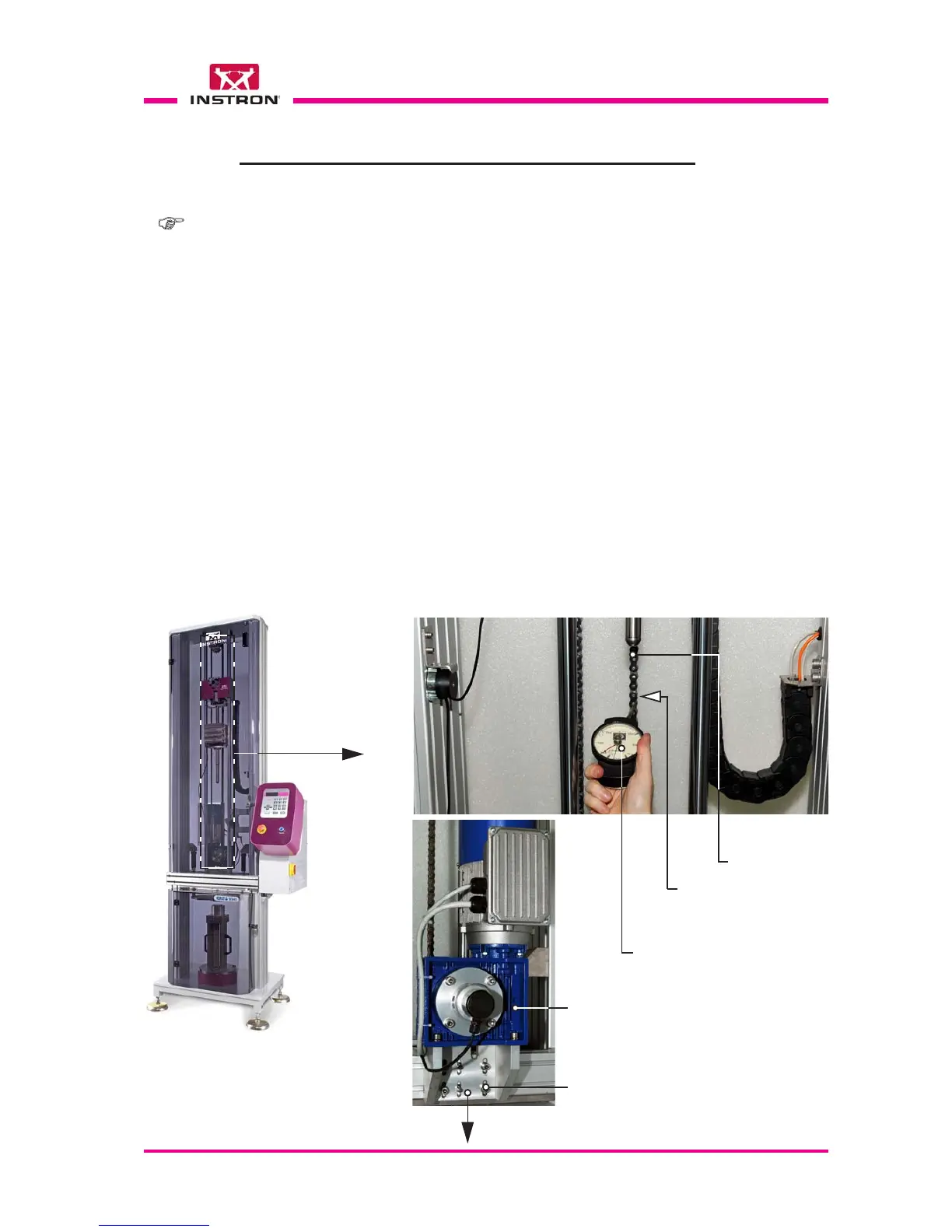

d) Place the end of a dynamometer (see figure) in the middle of the chain (right side)

and stress it applying a load of 1 kgf (9.81 N).

e) The deflection of the chain must be less than 8-10 mm, otherwise extend the chain.

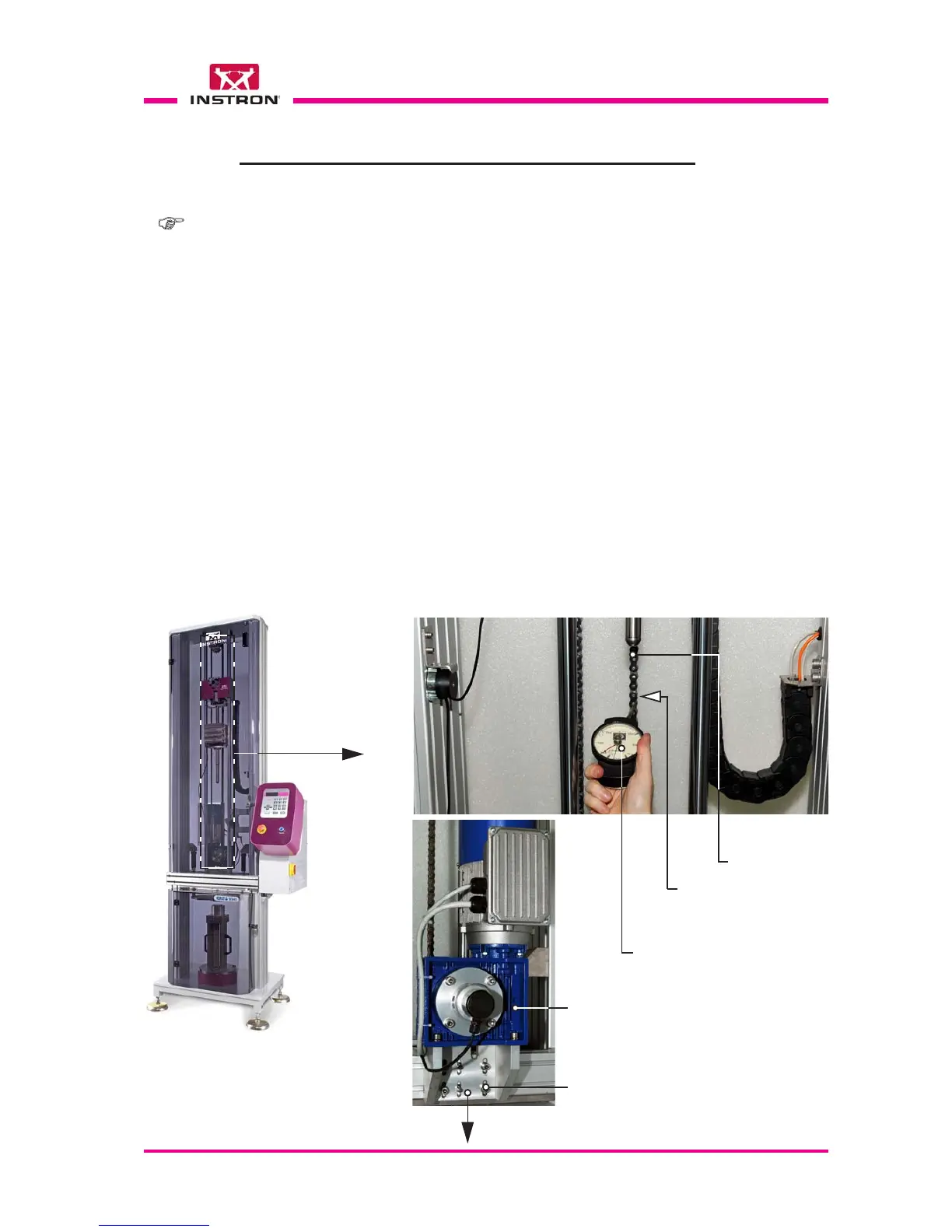

f) Loosen the screws of the ratiomotor support (see figure) push downward the ratiomotor

and tighten the screws.

If the screws are in contact with the slot ends and it is not possible to adjust the chain,

shorten the chain by removing a link.

g) Proceed with the instructions of steps d), e) and f) until to measure the correct deflection.

Dynamometer

Gearing chain

Direction of the force

applied on the chain

by dynamometer

Note:- The gearing chain needs to be checked every 5000 releasing cycles and/or after

repeated tests in which the striker is jammed in the specimen and the lifter motor

subjected to a traction effort stops repeatedly.

Ratiomotor

Screw (x4)

Loading...

Loading...