136 Kollmorgen - December 2011

MMC Smart Drive Hardware Manual - 460V 3 PHASE MMC SMART DRIVE NEXTGEN

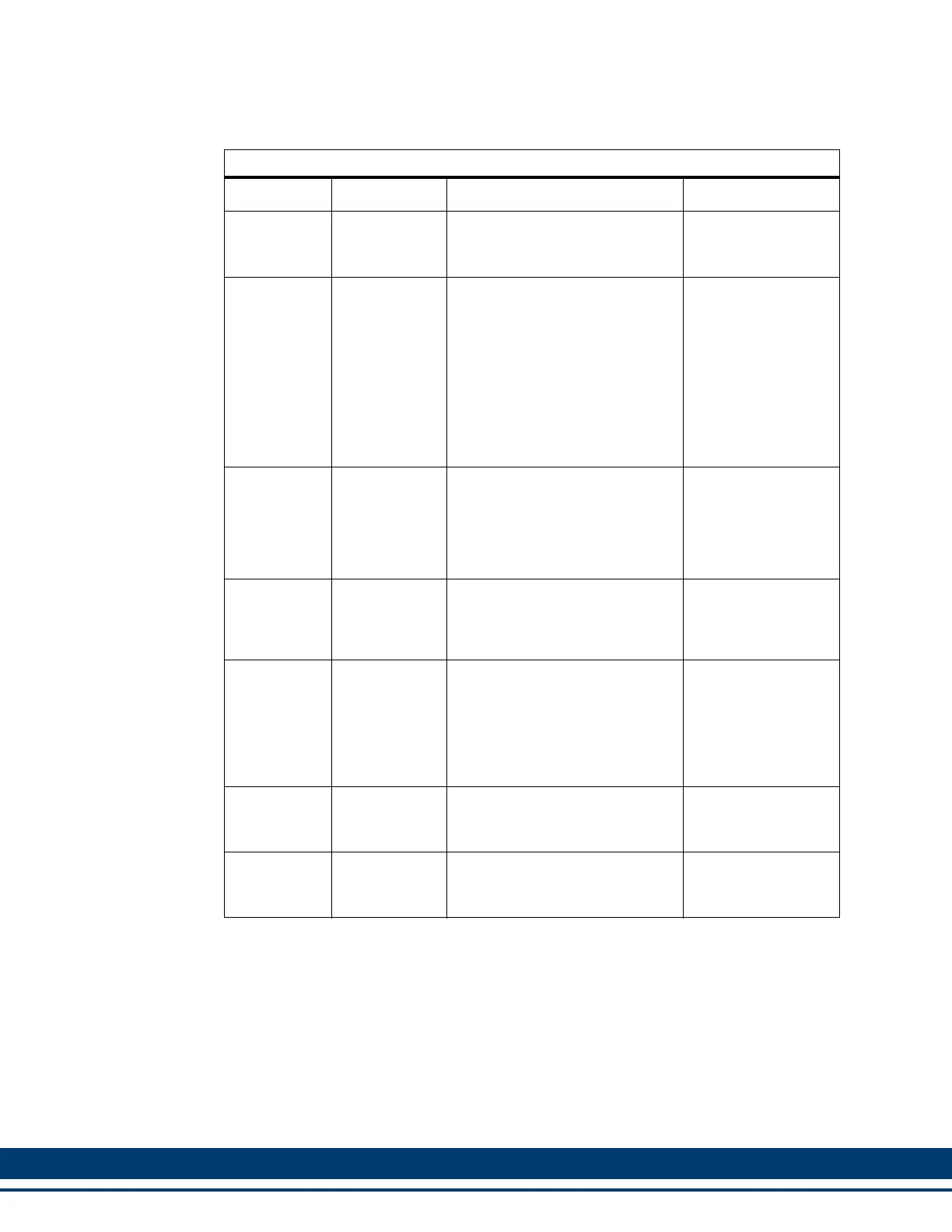

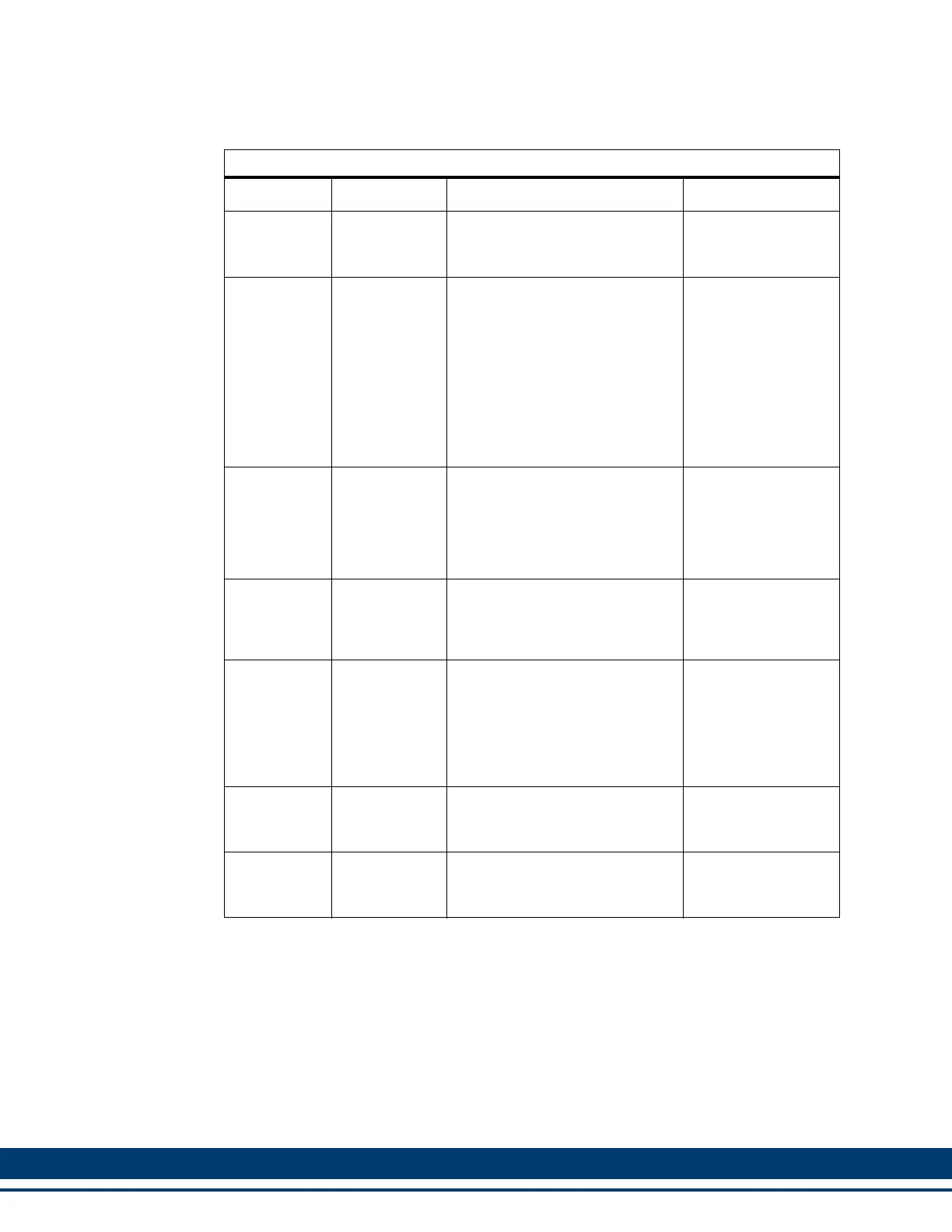

Table 6-6: Pin Description for Feedback Connector (F2)

Signal Type Signal Name Notes Pin

Incremental

Encoder In-

puts

A1, A1/, B1,

B1/, I1, I1/

Differential A quad B encoder

signals. These can be defined

as inputs or outputs in PiCPro.

12, 13, 14, 15, 6, 7

Buffered F1

Encoder

Output

A1, A1/, B1,

B1/, I1, I1/

RS485 drivers are used and the

signal that is output depends on

the encoder or resolver type

used. See specifications in sec-

tion 6.3 on page 159 of this

manual. These signals are gen-

erated after the feedback from

the F1connector is filtered and

processed. These can be de-

fined as inputs or outputs in

PiCPro.

12, 13, 14, 15, 6, 7

Motor Com-

mutation

Hall Sensor

Inputs

S1, S2, S3

Hall-device input signals that

are used to initialize the motor

commutation angle. They con-

sist of a 74HC14 input with a

10μs filter and a 2.2K pull-up to

+5V. Shared with F1.

1, 2, 3

SFD Com-

munication

Channel (fu-

ture)

Com+, Com- SFD communication signals 6, 7

Tempera-

ture Input

Temperature

Thermostat (normally- closed)

or Thermistor (Phillips KTY84-

130 PTC or equivalent recom-

mended) input for detecting

over temperature conditions

within the motor. These inputs

are shared with F1.

8, 9

+5V Encod-

er Power

Output

+5V Source

Regulated +5VDC for powering

the attached encoder (200ma

max).

10

Signal and

Power Com-

mon

Common

Return path for feedback sig-

nals and +5V power output

11

Loading...

Loading...