Chapter 5 - page 13

Operator’s manual ASTRONAUT

M-HE.002.1003

5.3.7 M4USE separation arm (optional)

The abbreviation M4USE stands for milk for use.

Separation arm operation

The separation arm is electronically controlled. It has 5

positions i.e. one sewer- and four bucket positions.

When milk needs to be separated, first bucket 1 is filled (buckets

are numbered starting from the sewer side). This is recorded on

a screen on the robot box. Bucket 2 is filled with the milk of the

next separation cow.

The buckets can contain 15 l of milk. If a cow produces 18 l of

milk that needs to be separated:

• The amount of milk is divided into two buckets each with 9

l of milk.

• If there is only one empty bucket left, 14 l will be pumped

into that bucket and 4 l will be dumped into the sewer.

• If all buckets are full, the milk will be dumped into the sewer.

Milk in the buckets

The main menu of the robot screen shows which bucket contains the milk of which cow. Go to the option "Quality"

in the main menu.

Select "Quality"

Select "MQC - MILK separation"

The screen shows that bucket 1 is filled with milk from the cow with responder

no. 100 milked at 02:00 hrs. in the morning. Bucket 2 is filled with milk from

cow with responder no. 109 milked at 04:10 hrs. in the morning. The buckets

3 and 4 are empty and are ready to be used.

AS milk stands for: automatically separated by MQC

MS milk stands for: manually separated in Expert.

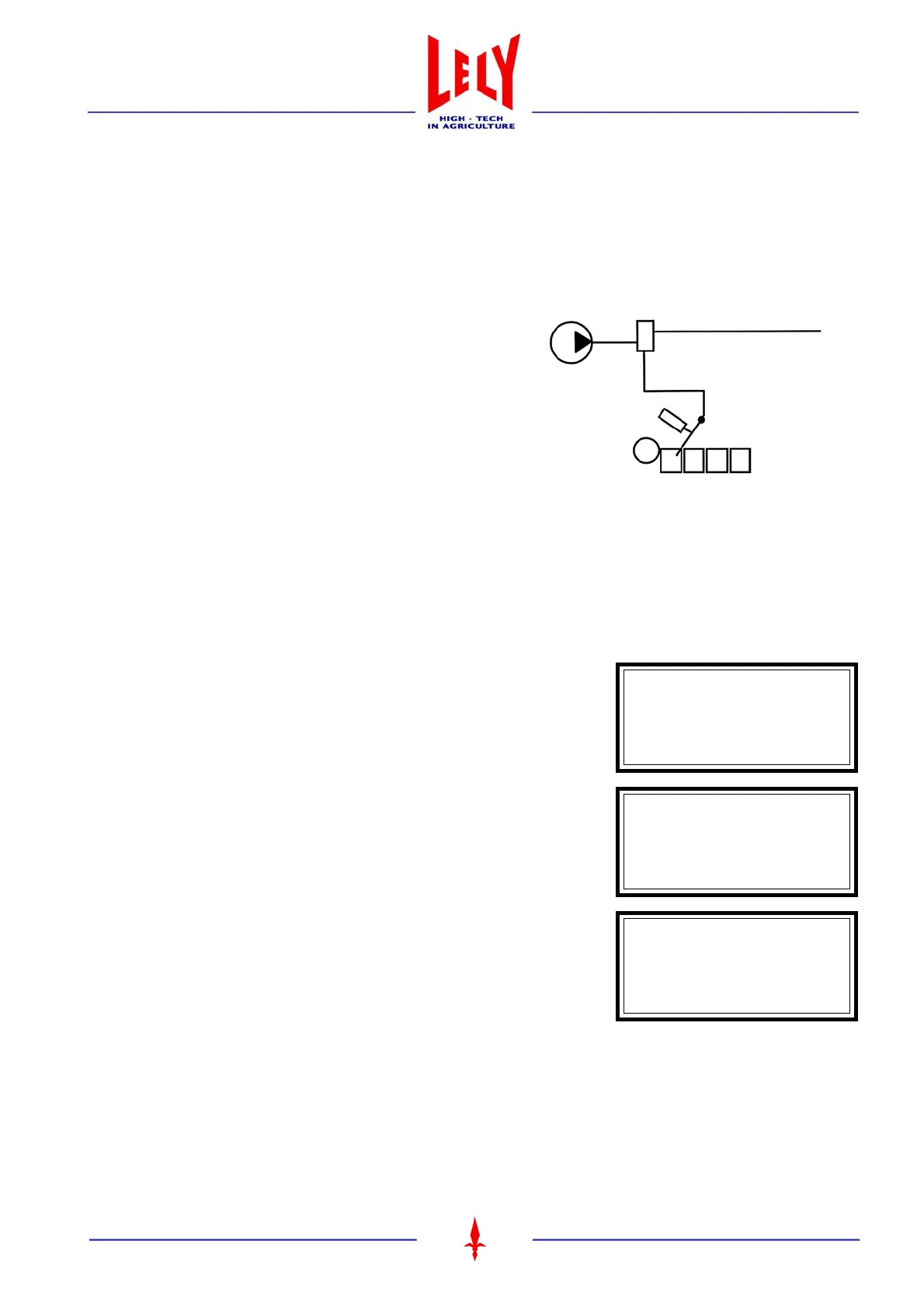

Figure 5.11 M4USE system schematic

(RH-model)

Milk pump

To milk tank

Electric

actuator

Sewer

Buckets

1 2 3 4

15:22 Testmenu

Quality

Operational

Attentions

MQC - MILK separation

MQC - Conductivity

MQC - Temperature

MQC - Colour

Cow 100 02: 00 AS

Cow 109 04: 10 MS

Free

Free

Loading...

Loading...