Chapter 3 Before positioning

3- 45

Remark

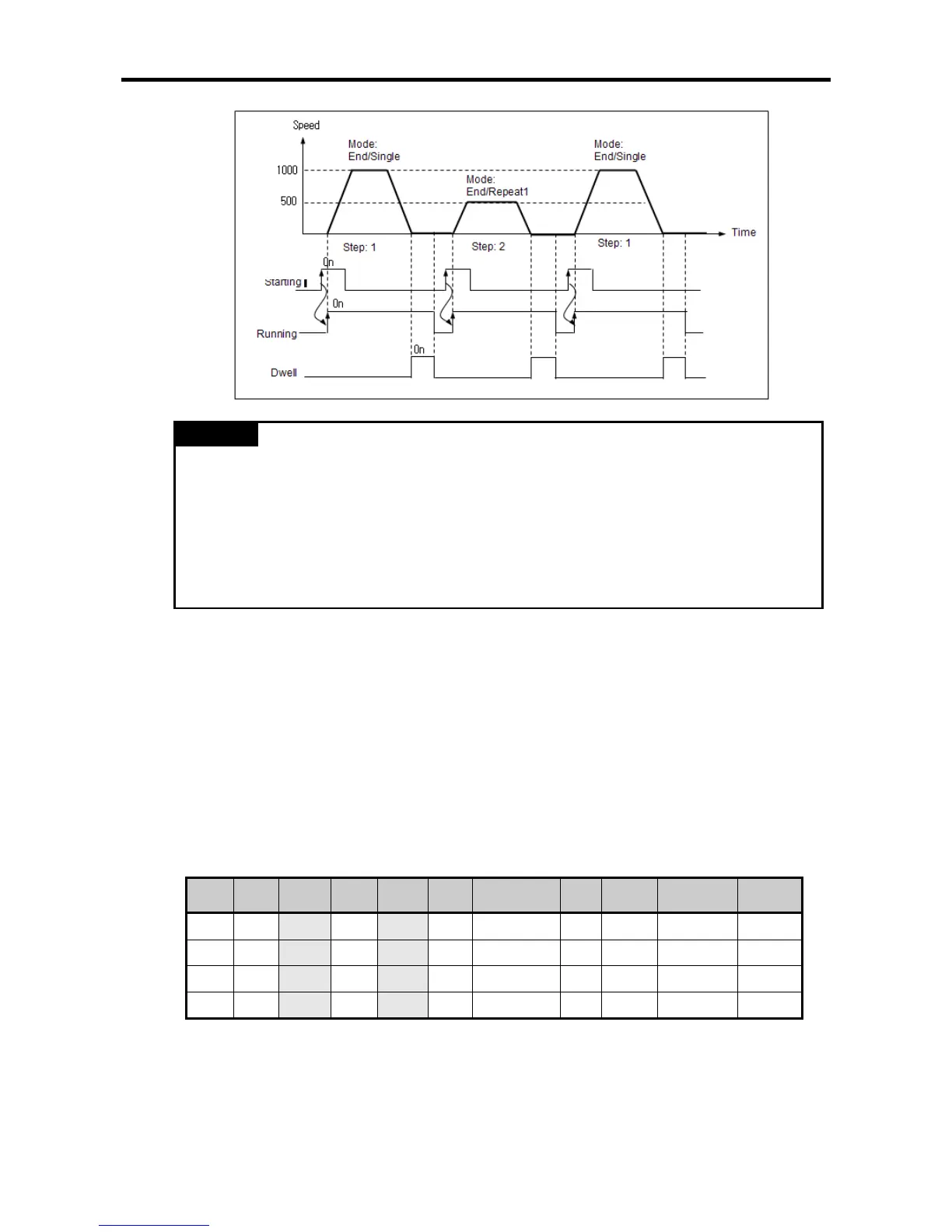

•If the operation mode is set as single, set the operating step number in the IST at 0, then the

step specified in the current step number (axis X: K426(%KW426), axis Y: K436 (%KW436))

in area K for positioning.

•If the operation mode is set as Repeat and the Repeat step is set at 0, the step stops operating

and the next step changes into 0.

In this case, the operating step gets out of the range of 1~30 (1~80 for the compact

standard/high-end type) and error code 512 comes out, so be careful of the repeating step

setting when you set at the repeating operation.

(c) Continued Operation

•Continued operation refers to the operation which carried out positioning to the target position by

using the data of the corresponding operating step by the operation instruction and continues the

next operating steps without any additional operation instructions with the positioning not completed

after the dwell time.

•The next operating steps differ according to the current operating mode of the steps.

A) The operation mode of the current step is single: current operating step + 1

B) The operation mode of the current step is repetition: the step designated as Repeat in the current

operation step

•If you use the continued operation pattern, you can conduct the pattern operation that sequentially

carried out multiple operating steps with only one operation instruction.

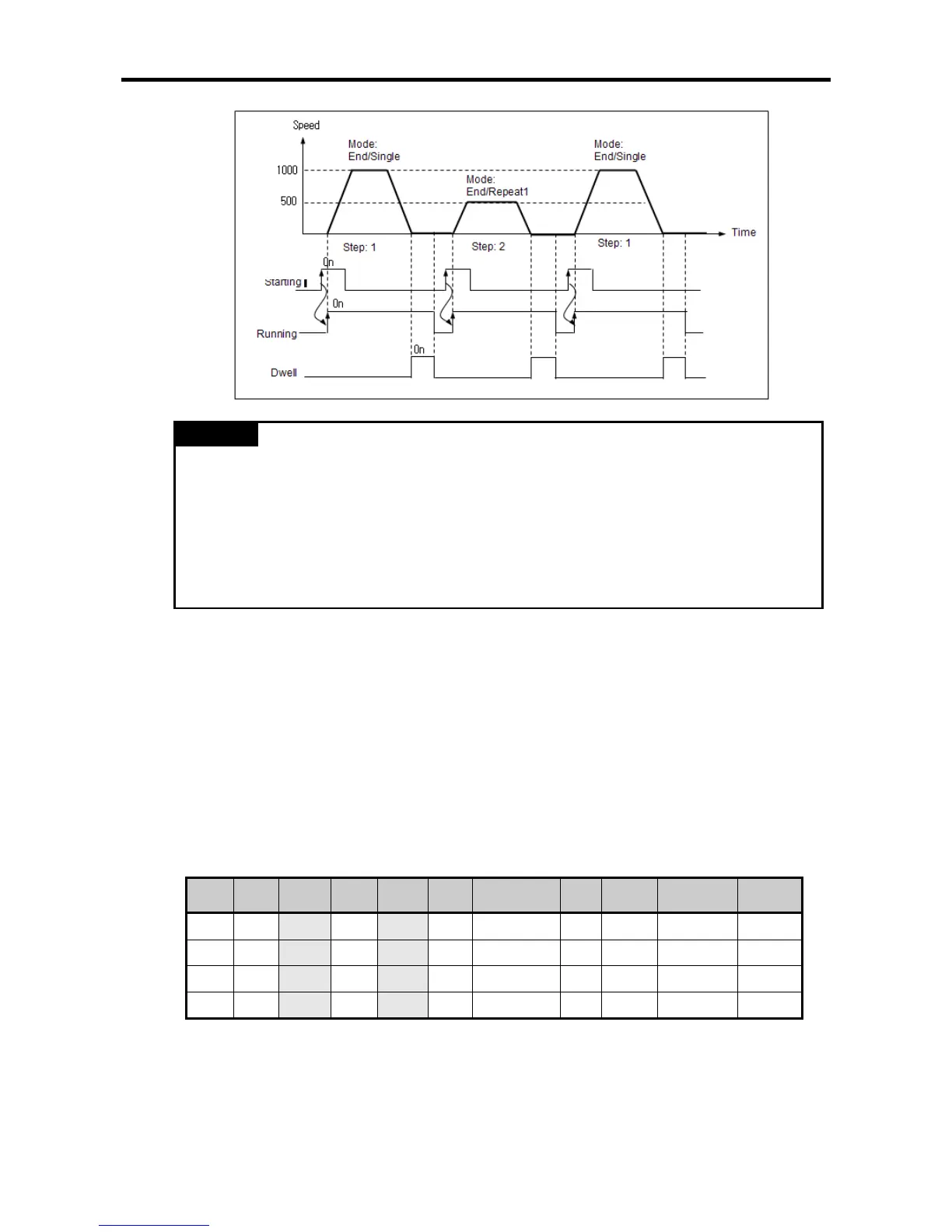

•The continued operation can be explained with the operation data in the following table.

Step No.

Coordina

tes

Operation

pattern

Control

Operation

mode

Repeatin

g step

Target position

[Pulse]

M

code

Acc./Dec.

No.

Speed

[pls/s]

Dwell time

[㎳]

1 Absolute Keep Position Single 0 10,000 0 0 1,000 100

2 Absolute Keep Position Single 0 20,000 0 0 500 100

3 Absolute End Position Single 0 30,000 0 1 1,000 0

4 Absolute End Position Repeat 1 40,000 0 1 500 0

1) Steps 1 and 2 are continued in the operation pattern and single in the operation mode, so they

operate at 1,000pps to the pulse of absolute coordinates 10,000 and then operates step 2, the

next step, without waiting for the next operation instruction when the dwell time passes. If the

dwell time passes after step 2, step 3 is operated.

2) Step 3, of which the operation pattern is end, operates up to absolute coordinates 30,000, and

then stops right away because the dwell time is 0, and the positioning completion bit turns on

for a scan.

Loading...

Loading...