How do I resolve the issue of a specified digital value being outside the range on my Mitsubishi MELSEC Q Controller?

- AAaron ThomasSep 2, 2025

Set a value that is within the range.

Loading...

Loading...

How do I resolve the issue of a specified digital value being outside the range on my Mitsubishi MELSEC Q Controller?

Set a value that is within the range.

What should I do if the value set to the intelligent function switch 5 is other than 0 in Mitsubishi MELSEC Q?

Re-set the correct parameter value in the parameter setting of GX Developer.

What to do if there is an invalid value in offset/gain setting and the error channel number cannot be identified on Mitsubishi Controller?

Perform the offset/gain setting again for all of the channels that use the user range settings. If the error occurs again, the module may be malfunctioning. Please consult your local Mitsubishi representative, explaining a detailed description of the problem.

How to correct warning output lower limit value equal to or greater than the warning output upper limit value on Mitsubishi MELSEC Q Controller?

Make setting so that the warning output upper limit value is greater than the warning output lower limit value.

How to solve scaling lower limit value equal to or greater than the scaling upper limit value on Mitsubishi Controller?

Set CH scaling upper/lower limit value so that the scaling upper limit value is greater than the scaling lower limit value.

How to fix offset value equal to or larger than gain value on Mitsubishi MELSEC Q?

Reset the Mitsubishi Controller so that the offset value is smaller than the gain value.

What to do if an invalid value is set in the offset/gain setting on Mitsubishi MELSEC Q?

Perform the offset/gain setting again for the error channel. If the error occurs again, the module may be malfunctioning. Please consult your local Mitsubishi representative, explaining a detailed description of the problem.

What should I do if the analog output value is not “HOLD” on my Mitsubishi MELSEC Q Controller?

If the analog output value is not in “HOLD” mode, check the Switch 3 setting of the intelligent function module switch setting on GX Developer. Also, if the Q66DA-G is used on a MELSECNET/H remote I/O station, take action, referring to POINT (2) in Section 3.2.1.

Why is the analog value not within the reference accuracy of the theoretical value on my Mitsubishi MELSEC Q?

If you're using voltage output and observe a small load resistance of the connected external device and a long wiring distance, a voltage drop due to the wiring impedance and load current may be large, and the voltage applied to the external device is low. In this case, the factory default range setting may not satisfy the reference accuracy. Use User range setting and adjust the offset and gain values after wiring.

Why is the RUN LED flashing or off on my Mitsubishi Controller?

The RUN LED might be flashing or turned off if the mode is set to the offset/gain setting mode. Reset switch 4 of the intelligent function module switch setting for GX Developer to the normal mode.

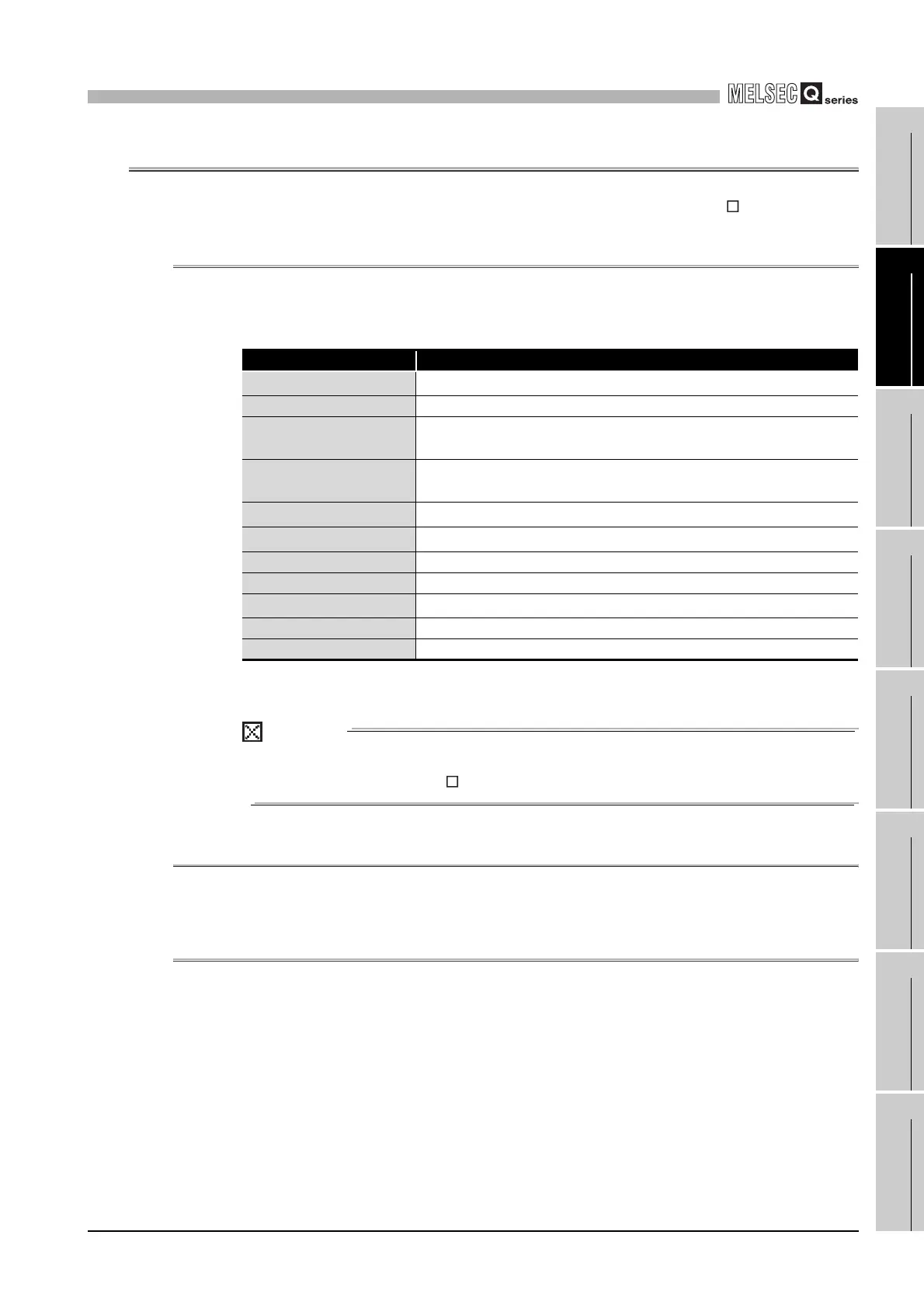

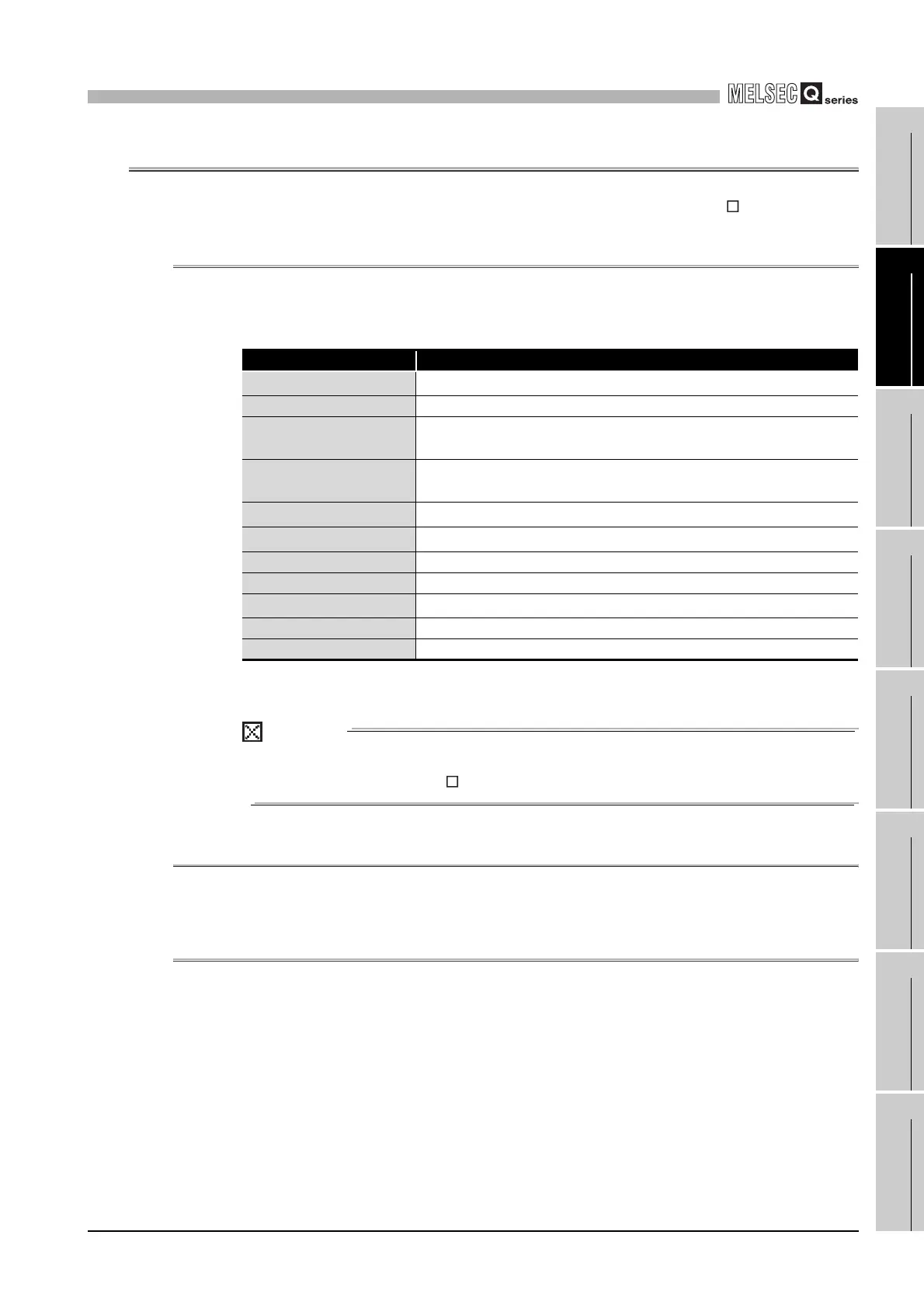

| Series | MELSEC Q Series |

|---|---|

| Type | Modular PLC |

| Programming Software | GX Works2, GX Works3 |

| Category | Programmable Logic Controller (PLC) |

| I/O Modules | Digital I/O, Analog I/O, High-Speed Counter, Positioning |

| Communication | Ethernet, CC-Link |

| Programming Languages | Ladder Logic, Structured Text, Function Block Diagram, Sequential Function Chart, Instruction List |

| Memory | Flash Memory |

| I/O Points | Up to 4096 points (expandable with additional modules) |

| Power Supply | AC or DC power supply options available, depending on the base unit and modules. |

| Mounting | DIN rail mounting |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -25°C to 75°C |

| Humidity | 5% to 95% (non-condensing) |

| Vibration Resistance | 10 to 57 Hz, 0.075mm amplitude |

| Weight | Varies depending on the module, from a few grams to several kilograms. |

| Shock Resistance | 147 m/s² (3 times each in X, Y, Z directions) |

Describes the features of the C Controller module, including VxWorks, standard ROM, large data storage, and I/O control capabilities.

Explains device configuration, development environment connection, and system configuration overview for C Controller systems.

Details the base units, extension cables, power supply modules, and other components used with the C Controller module.

Provides the general specifications of the C Controller module, including operating ambient temperature, humidity, vibration, and shock resistance.

Lists the functions of the C Controller module, such as I/O module access, remote operation, and self-diagnostic functions.

Explains critical handling precautions for the C Controller module, including environment, installation, and connection safety.

Explains how base units and slots relate to I/O number assignment for the C Controller module.

Explains user memories (Standard ROM, Work RAM, Battery-backed-up RAM, CompactFlash) and system memory.

Details the product requirements for the development environment, including personal computer specifications and operating system.

Explains common operations for utilities, including starting, exiting, setting connection targets, and displaying help screens.

Outlines bus interface functions and MELSEC data link functions supplied with SW PVC-CCPU for accessing modules and CPUs.

Defines the multiple CPU system concept, explaining how multiple CPU modules work together for enhanced performance.

Explains system configuration for multiple CPU systems, including device compatibility and connection methods.

Details the mounting positions of CPU modules (C Controller, Basic QCPU, High Performance QCPU, Motion CPU) in a multiple CPU system.

Explains data communication methods using MELSEC data link functions between CPU modules, including auto refresh and shared memory.

Lists parameters required for multiple CPU system operation, highlighting setup necessity and consistency checks in the C Controller setting utility.

Provides specific precautions for using AnS series modules, including applicable I/O and special function modules and control CPU settings.

Provides fundamental steps for troubleshooting, including visual checks, fault verification, and narrowing down the error cause.