3

9850067 R01 - 2020-2021 GENERAL / GENERAL XP Service Manual

© Copyright Polaris Inc.

3.37

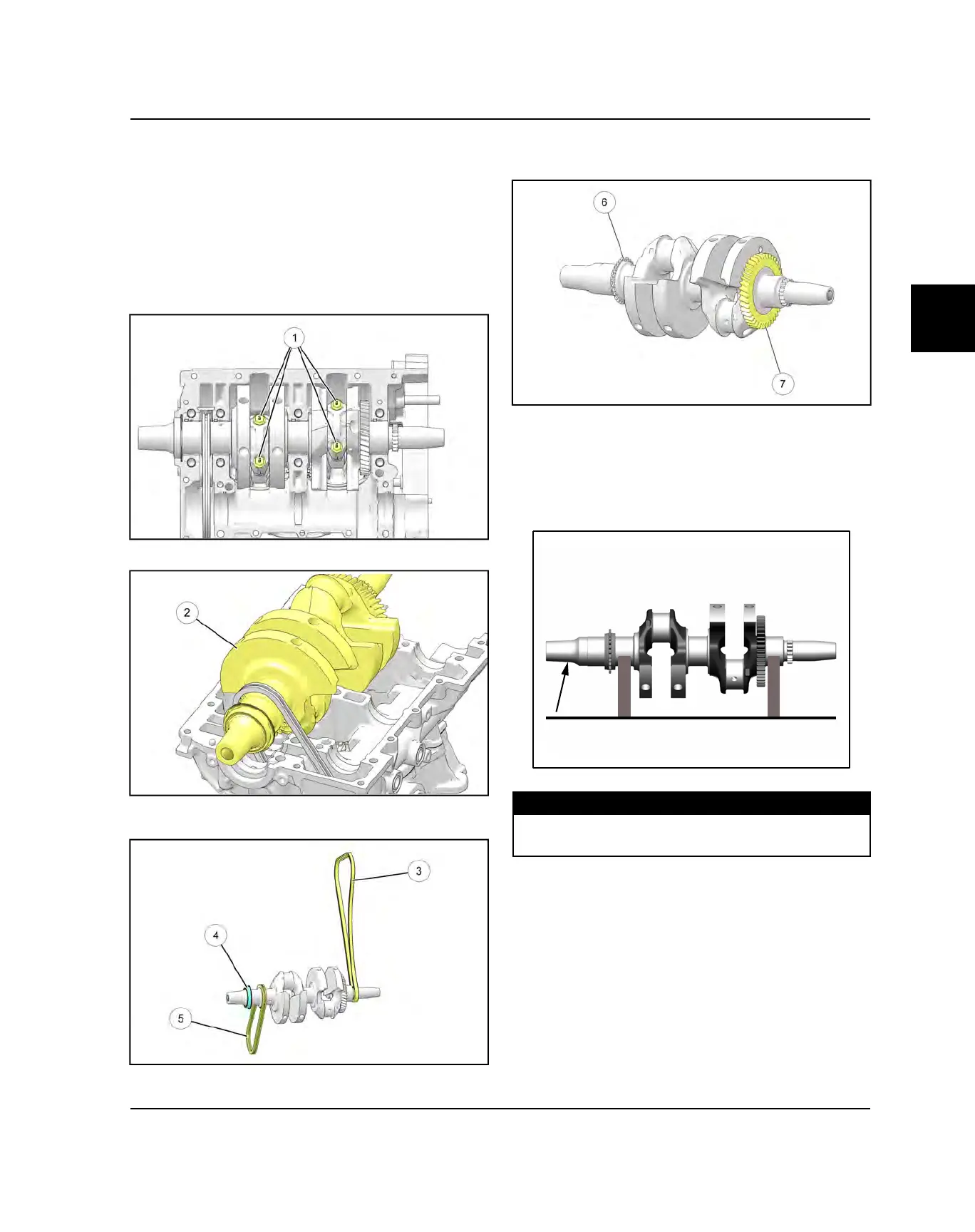

CRANKSHAFT REMOVAL / INSPECTION

1. Perform Crankcase Disassembly / Inspection page

3.33 procedure.

2. Perform Balance Shaft Removal / Inspection page

3.36 procedure.

3. For ease of assembly, mark each connecting rod and

end cap.

4. Loosen, remove and discard the four connecting rod

bolts

q

. Remove the end caps from the crankshaft.

5. Carefully lift the crankshaft

w

out of the crankcase.

6. Remove the cam chain

e

, oil pump drive chain

t

and PTO main seal

r

from the crankshaft.

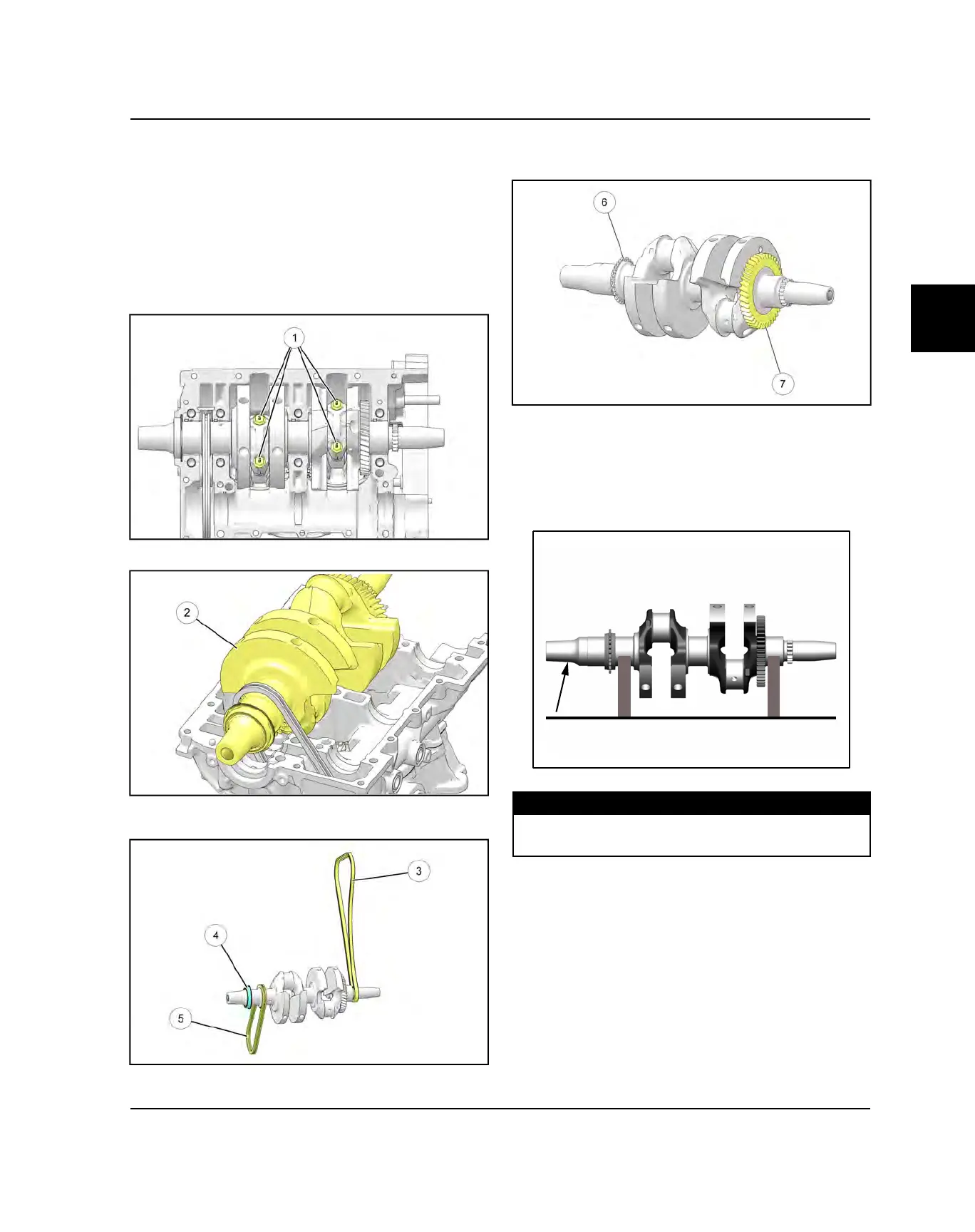

7. Inspect the crankshaft gear

u

and auxiliary sprocket

y

for broken or worn teeth.

8. If the crankshaft gear or sprocket is damaged, the

crankshaft assembly must be replaced.

9. Support crankshaft on V-blocks or on-centers in a

crankshaft stand or lathe. Measure crankshaft run-

out and replace if run-out exceeds maximum listed

below.

MEASUREMENT

Crankshaft Maximum Runout:

Less than .001″ (0.025 mm)

10. Visually inspect surface of crankshaft main and

connecting rod journals. Replace crankshaft if any

journal is scratched or pitted.

ENGINE / COOLING SYSTEM

Loading...

Loading...