Description of the device

Vacuum spray degassing — 20.05.2019

English — 9

Degassing

The entire degassing process is hydraulically regulated using the integrated pressure sensor and the device controller. The system

monitors the operating states and displays them at the controller. The controller provides 3 different degassing programmes and 2

different make-up variants for selection and setting.

Degassing programmes

For continued degassing over several hours or days in a sequence of degassing cycles without idling

periods.

This programme is recommended after commissioning and repairs.

comprises a limited number of degassing cycles. There is an idling time between the

intervals. This programme is recommended for continuous operation.

-up degassing:

-up degassing is automatically activated for every water make-up during continuous or interval

degassing in Magcontrol and Levelcontrol operating modes. Activation takes electrically by application of

an external make

-up request from the pressure maintenance station

-up motorized ball valve is opened and the system motorized ball valve is closed.

Make-up variants

There are two make-up variants. Both are monitored via the make-up time and the make-up cycles.

Note!

For pipe lengths greater t

han 8 m we recommend selecting the next largest nominal diameter DN 20. Max. pipe

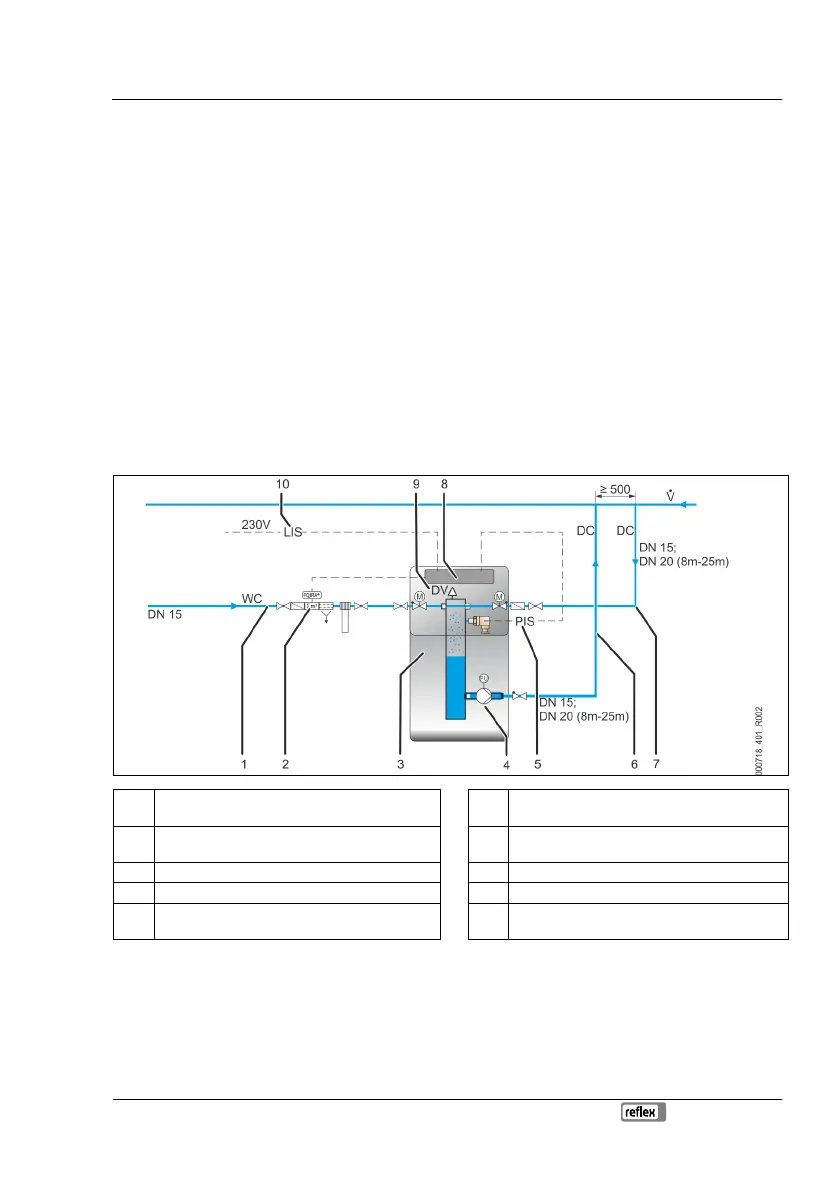

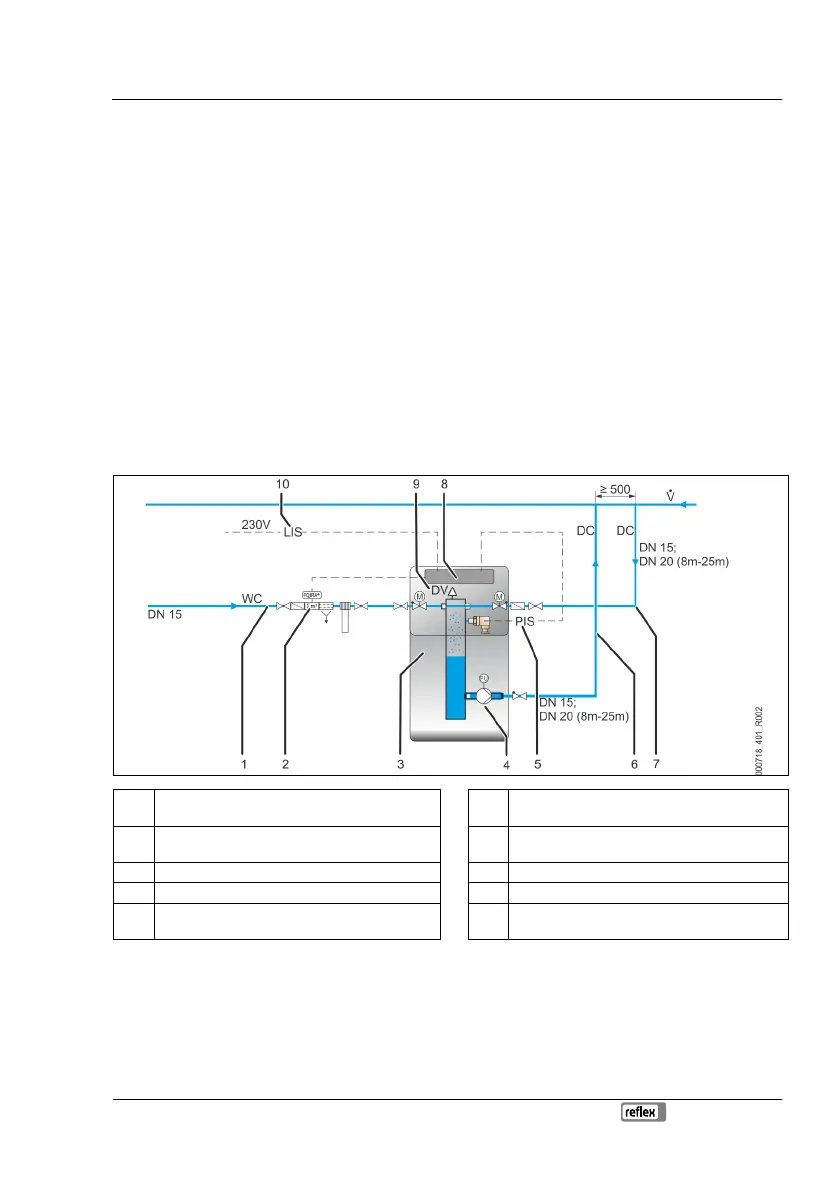

1 “WC” make-up line nominal diameter DN 15 6 “DC” degassing line (degassed water to the facility

system), nominal diameter DN 15; DN 20 (8 m-25 m)

2 Optional add-on device (see Chapter Optional

equipment and accessories)

7 “DC” degassing line (gas-rich water from the facility

system), nominal diameter DN 15; DN 20 (8 m-25 m)

3 Device 8 Device controller

4 "PU" vacuum pump 9 "DV" degassing valve

5 "PIS" pressure transducer from the device 10 Signal line from the "LIS" level sensor of a pressure

maintenance station

bladder expansion vessels.

– Using the integrated "PIS" pressure sensor, the system registers and monitors the pressure in the

heating or cooling system. Make-up degassing is activated as soon as the pressure drops below the

calculated filling pressure.

For systems with pressure maintenance stations.

– The pressure maintenance station uses the "LIS" pressure pick-up to determine the water level in the

expansion vessel. The make-up function is triggered by a 230 V signal.

Loading...

Loading...