Vacuum spray degassing — 20.05.2019

English — 15

Proceed as follows:

• Connect the "DC" degassing lines in the "V" main volume flow of the facility system.

• The device requires two "DC" degassing lines to the facility system.

– One degassing line for the gas-rich water from the facility system

– One degassing line for the degassed water back to the facility system.

• Fit the degassing lines near the "EC" expansion line.

– This ensures stable pressure conditions.

• Install the device near the "MAG" expansion vessel.

– This ensures pressure monitoring of the expansion vessel.

– Set the "Magcontrol" operating mode at the device controller.

Ensure the integration with the "V“ main flow volume. in particular in switching variants with hydraulic

switching points and return admixtures.

– For switching and make-up variants, see chapter 6.4 "Switching and make-up variants" on page 15 .

6.3.3.1 Make-up line

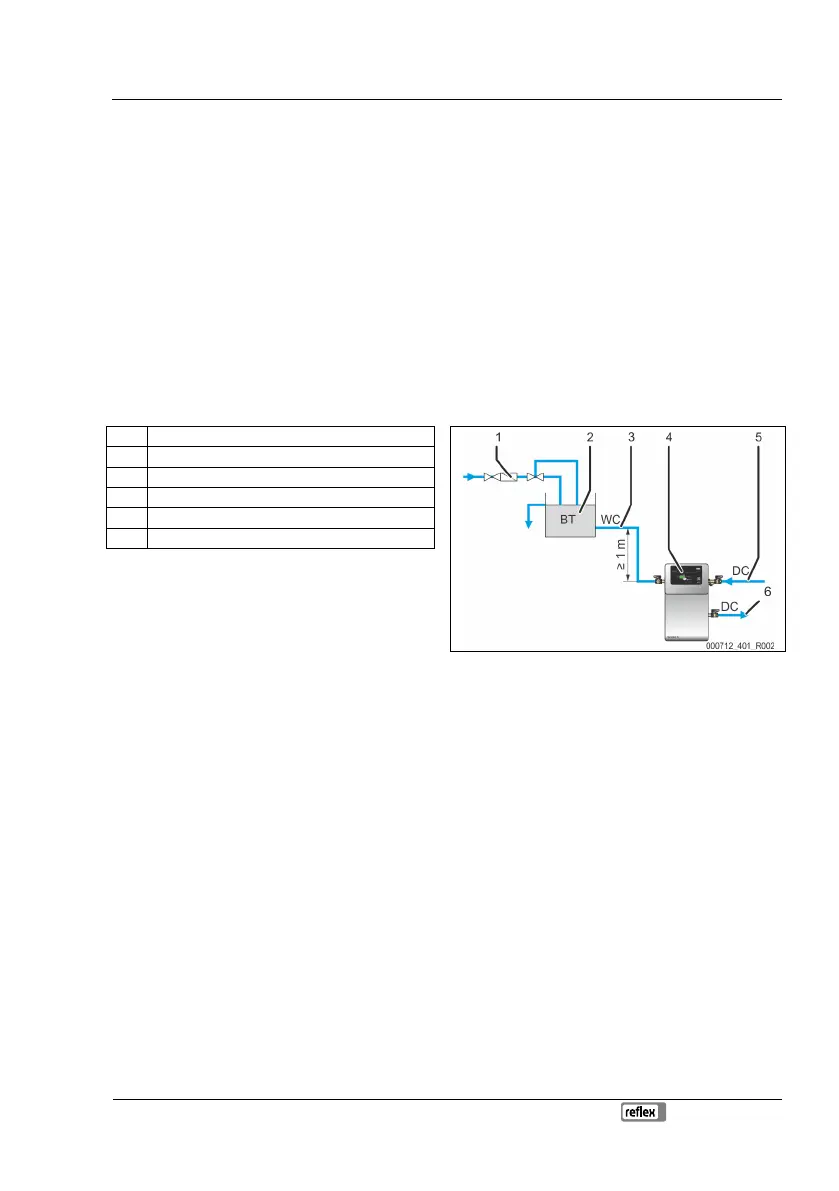

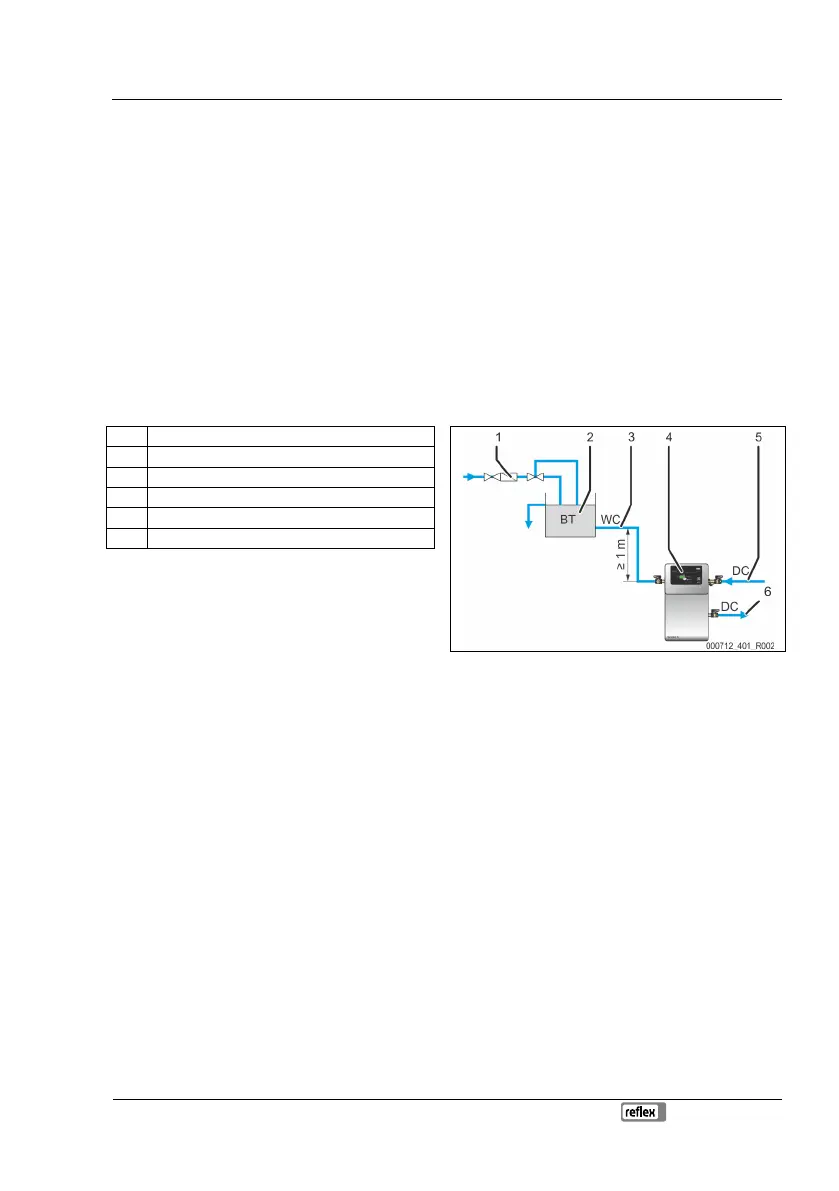

1 "ST" dirt trap

2 "BT" system separator vessel

3 "WC" make-up line

4 Device

5 "DC" degassing line (gas-rich water)

6 "DC" degassing line (degassed water)

For water make-up, note the following conditions:

• For a water make-up via a "BT" mains disconnect

receptacle, its bottom edge must be at least 1 m over

the "PU" device pump.

• Close the connection of the "WC" make-up line when a

make-up line is not connected.

– Adjust the "Levelcontrol" make-up variant at the

device controller.

• Install at least one "ST" dirt trap with a mesh size ≤ 0.25 mm close upstream to the "CD" 2-ways motorized ball valve.

Note!

Avoid a device fault.

Ensure that manual water make-up to the facility system is possible.

Note!

Use a pressure reducer in

the "WC" make-up line if the idle pressure exceeds 6 bar.

6.4 Switching and make-up variants

The device has two make-up variants:

• Pressure-dependent "Magcontrol" make-up.

– In a facility system with an expansion vessel.

• Level-dependent "Levelcontrol" make-up.

– In a facility system with a pressure maintenance station.

– As supplied, the device is preset to “Levelcontrol” operating mode. If no pressure maintenance station is connected,

pressure-independent degassing takes place without automatic make-up, see chapter 7.4 "Starting Automatic mode"

on page 21 .

Loading...

Loading...