Description of the device

— English Vacuum spray degassing — 20.05.2019

4.2 Identification

The nameplate provides information about the manufacturer, the year of manufacture, the manufacturing number and the

technical data.

Information on the type plate

Type Device name

Serial No. Serial number

min. / max. allowable pressure P Minimum/maximum permissible pressure

max. continuous operating temperature Maximum temperature for continuous operation

min. / max. allowable temperature / flow temperature TS Minimum / maximum permissible temperature / TS flow temperature

Year built Year of manufacture

min. operating pressure set up on shop floor Factory set minimum operating pressure

at site Set minimum operating pressure

max. pressure safety valve factory - aline Factory set actuating pressure of the safety valve

at site Set actuating pressure of the safety valve

4.3 Function

The device degasses the water from the facility system and the fresh water from the make-up line. It removes up to 90 % of the

dissolved gases from the water. The degassing operation uses timer-controlled cycles.

A cycle comprises the following phases:

1. Pump down to create a vacuum

The “PU” pump creates a vacuum. The “DC” feed (during “WC” make-up degassing) to the pump is open. Gas-rich water is

sprayed into the spray tube via a nozzle. The system is set up so that the pump draws more water from the pipe that can flow

through the nozzle.

2. Injection

The inlet to the "PU" vacuum pump is opened. Depending on the actual demand, a partial flow of the gas-rich system water

of the facility system or the fresh make-up water are introduced through the "DC" or "WC" lines of the device. The water is

then finely atomised in the vacuum pump. The large surface of the atomised water and the large gas saturation headway to

the vacuum result in a degassing of the water. The degassed water is returned to the system via the vacuum pump.

3. Discharge

The "PU" vacuum pump shuts off. The system continues to atomise and degas water. The water level in the vacuum pump

rises. The gases separated from the water are discharged into the surrounding atmosphere via the "DV" degassing valve.

4. Idling time

When the gas has been discharged, the device will remain idling until the next cycle is started.

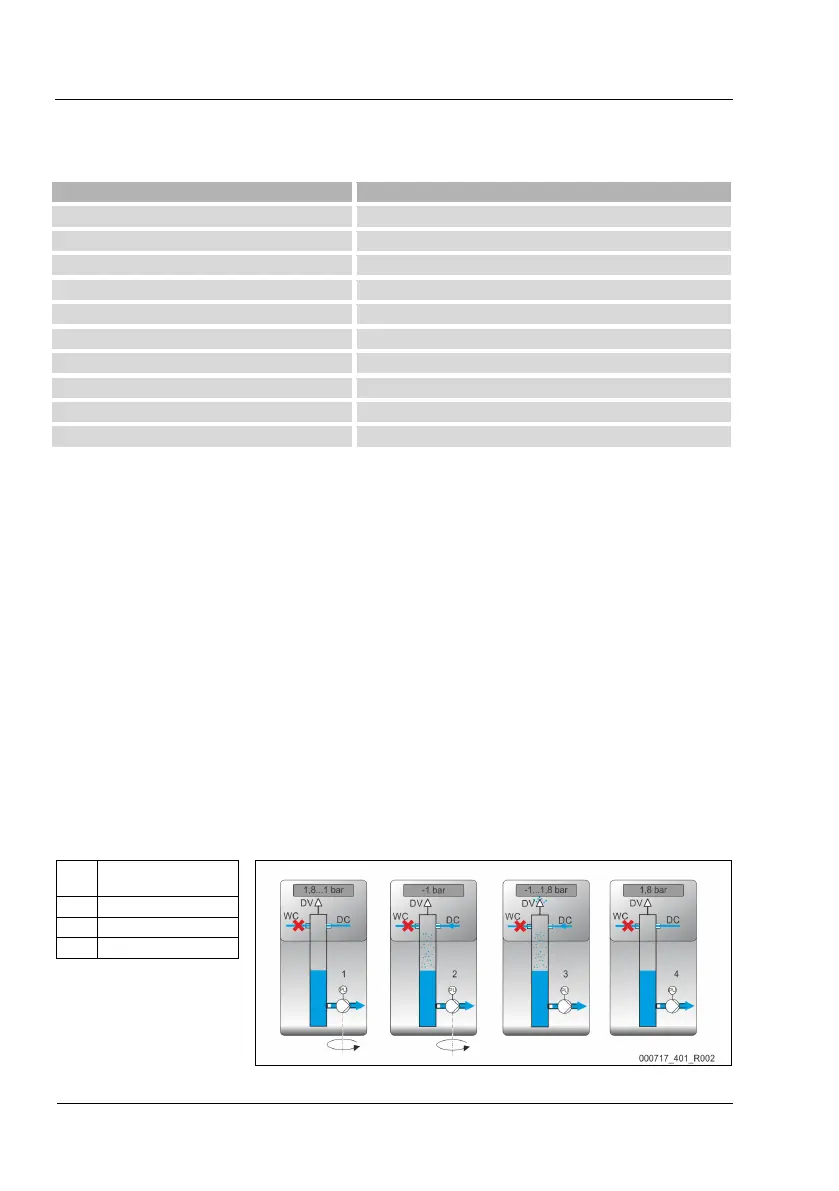

Degassing cycle in the PU vacuum pump

Cooling water system ≤ 30 °C, System pressure 1.8 bar, "DC" system degassing in operation, "WC" make-up degassing closed.

1 Pump down to create a

vacuum

2 Injection

3 Discharge

4 Idling time

Loading...

Loading...