5. OPERATION

IMR02L04-E3

5-4

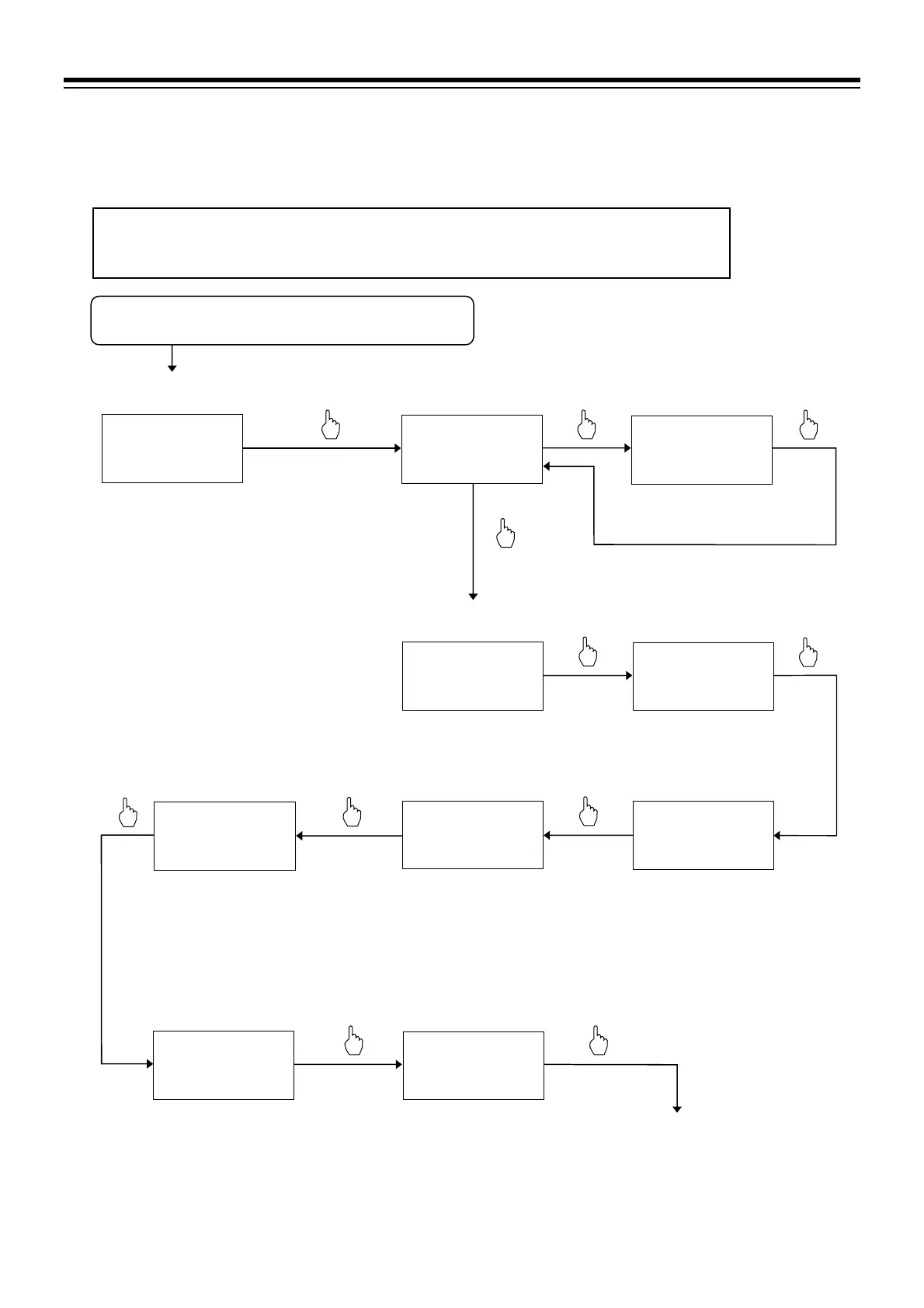

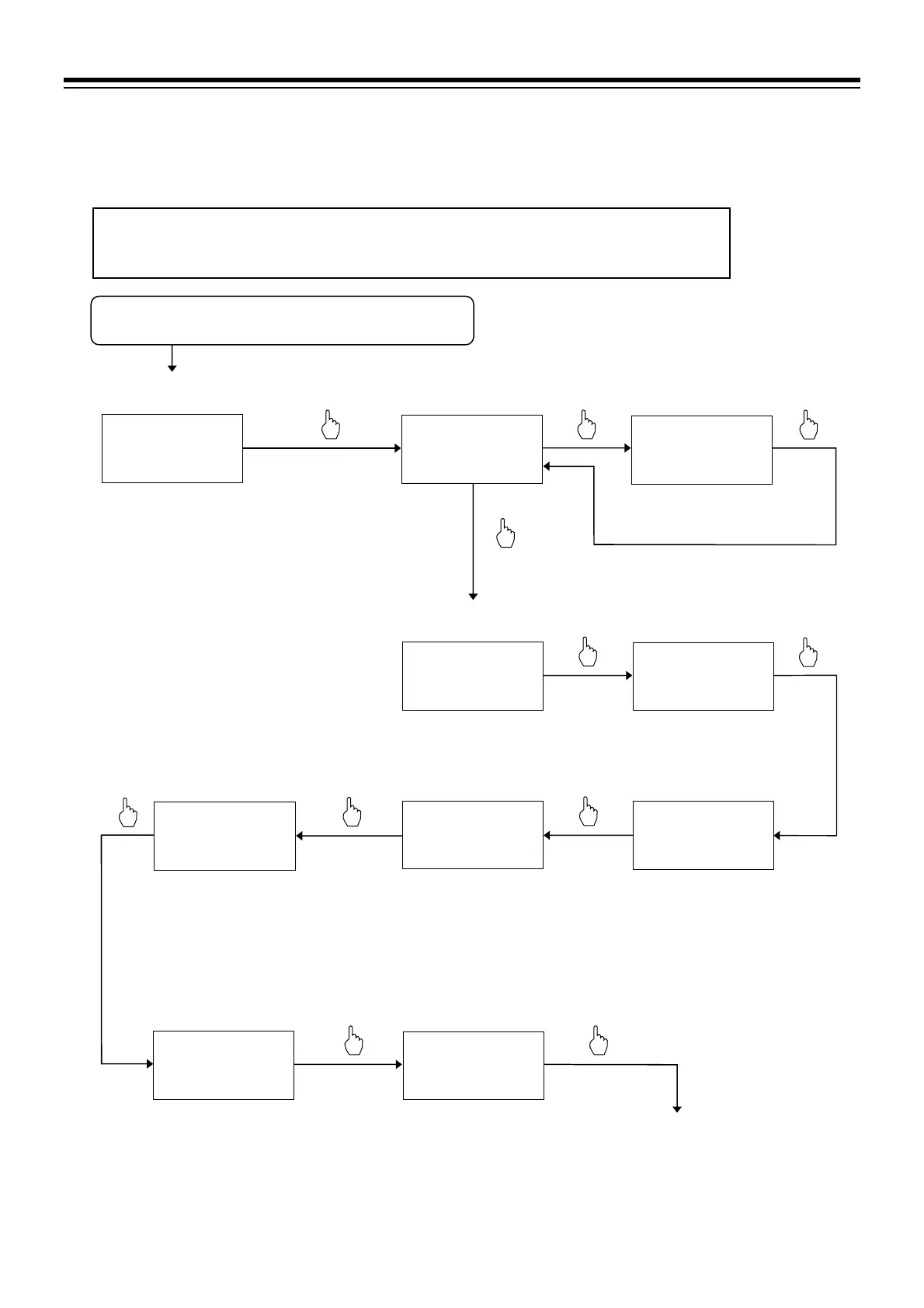

5.1.3 Check the parameter related to the control

Parameter settings related to control action can be checked at F50 in Engineering mode.

Parameters which are not specified when ordering must be set before use.

Setup example:

Control action: PID control (reverse action) [Suffix code: F]

Control output: OUT1, Relay contact output, Proportional cycle time: 20 seconds

After setting event action related parameters,

check and set parameters related to control actions.

PV

F41.

M:S

SV

FIX000RDEV1

Function block 41

(F41.)

PV

F50.

M:S

SV

FIX000CONTR

Function block 50

(F50.)

PV

KTIOS

M:S

SV

F50.01R 00001

Control action

Press the key

until F50 displays.

Check Control action.

00001:

PID control (reverse action)

PV

KTIPD

M:S

SV

F50.02R 00000

Hot/Cold start

Select Hot/Cold start.

00000: Hot start1 (Factory set value)

00001: Hot start2

00002: Cold start

00003: Reset start

PV

KTPDA

M:S

SV

F50.03R 00012

Start determination

point

Set Start determination point.

00012: 12 C

(Factory set value: 3 % of Input span)

[Range: 0 to Input span]

PV

K AOVE

M:S

SV

F50.04R 00000

Action (high) at input

error

Select Action (high) at input error.

00000: Normal control

(Factory set value)

00001: Manipulated output value at

input error

PV

K AUNE

M:S

SV

F50.05R 00000

Action (low) at input

error

Select Action (low) at input erro

.

00000: Normal control

(Factory set value)

00001: Manipulated output value at

input error

PV

KTPSM

M:S

SV

F50.06R 0000.0

Manipulated output

value at input error

Set Manipulated output value at

input error.

0000.0: 0.0 % (Factory set value)

[Range: 105.0 to 105.0 %]

Press the key

until F31 displays.

PV

F31.

M:S

SV

FIX000ROUT1

Function block 31

(F31.)

PV

LOGC1

M:S

SV

F31.01R 00000

OUT1 assignment

Check OUT1 assignment.

00000:

Manipulated output

value 1 (MV1)

Continue to the

next parameter

(P. 4-38) (P. 4-36)

(P. 4-41)

Loading...

Loading...