25

SITRANS F M

3. Project guidance

3.2.1

Minimum conductivity

Applications Min. conductivity

Compact/remote

DN 2 & 3 (DN ≥

1

/

12

&

1

/

8

inch) 30 μS/cm

DN ≥ 6 (DN ≥ ¼ inch) 5 μS/cm

With empty pipe detection 50 μS/cm

Ex-installations

(Remote mounted only)

30 μS/cm

District heating systems

(Without DC cleaning unit)

250 μS/cm max. 150 ft

3.2.2

Liner selection guide

Liner Applications

Zirconium oxide ZrO

2

General purpose, agressive chemicals

Ceramics Al

2

O

3

General purpose, food and beverage, agressive chemicals

PFA General purpose, food and beverage, pulp and paper, chemicals,

high temperature and chemical resistance

Neoprene Water and wastewater and some chemical applications

EPDM Drinking water applications, (not hydrocarbons)

PTFE Chemical and general process industries, high temperature and

chemical resistance

Linatex

®®

®®

®

Abrasive media and mining slurries

Ebonite Drinking water applications, wastewater applications and certain

chemical applications

NBR: General purpose, Drinking water, sea water

3.2.3

Electrode selection guide

Electrodes Applications

AISI 316 Ti General purpose, water, sewage and district heating

Hastelloy C The preferred choice for water and wastewater, chemicals, food

and beverage, and pharmaceutical industries

Titanium Process and chemical industry which require a high corrosion

resistance

Tantalum Chemical industry with aggressive media

Platinum and platinum/irridium The ultimate electrode material unaffected by most liquids

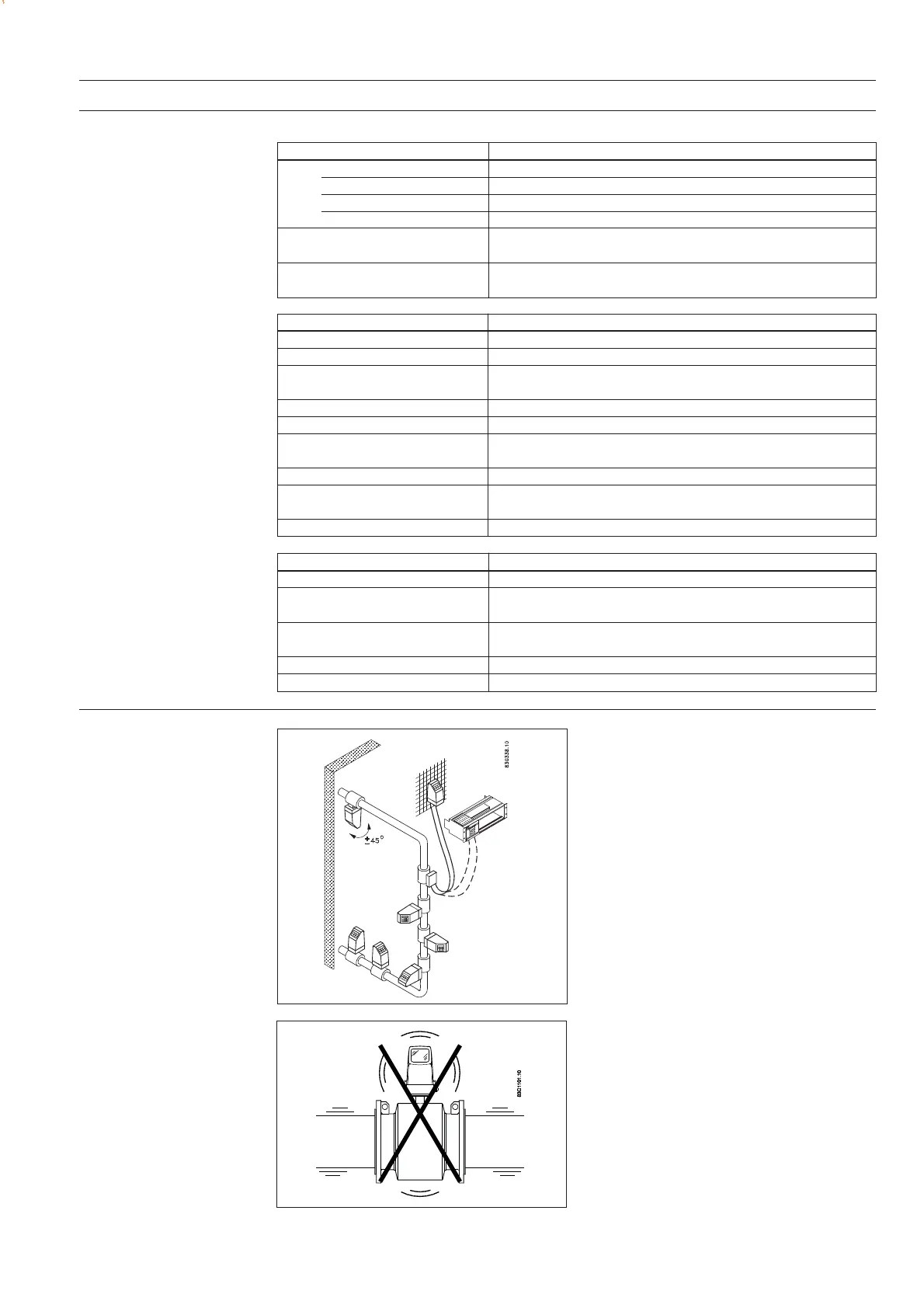

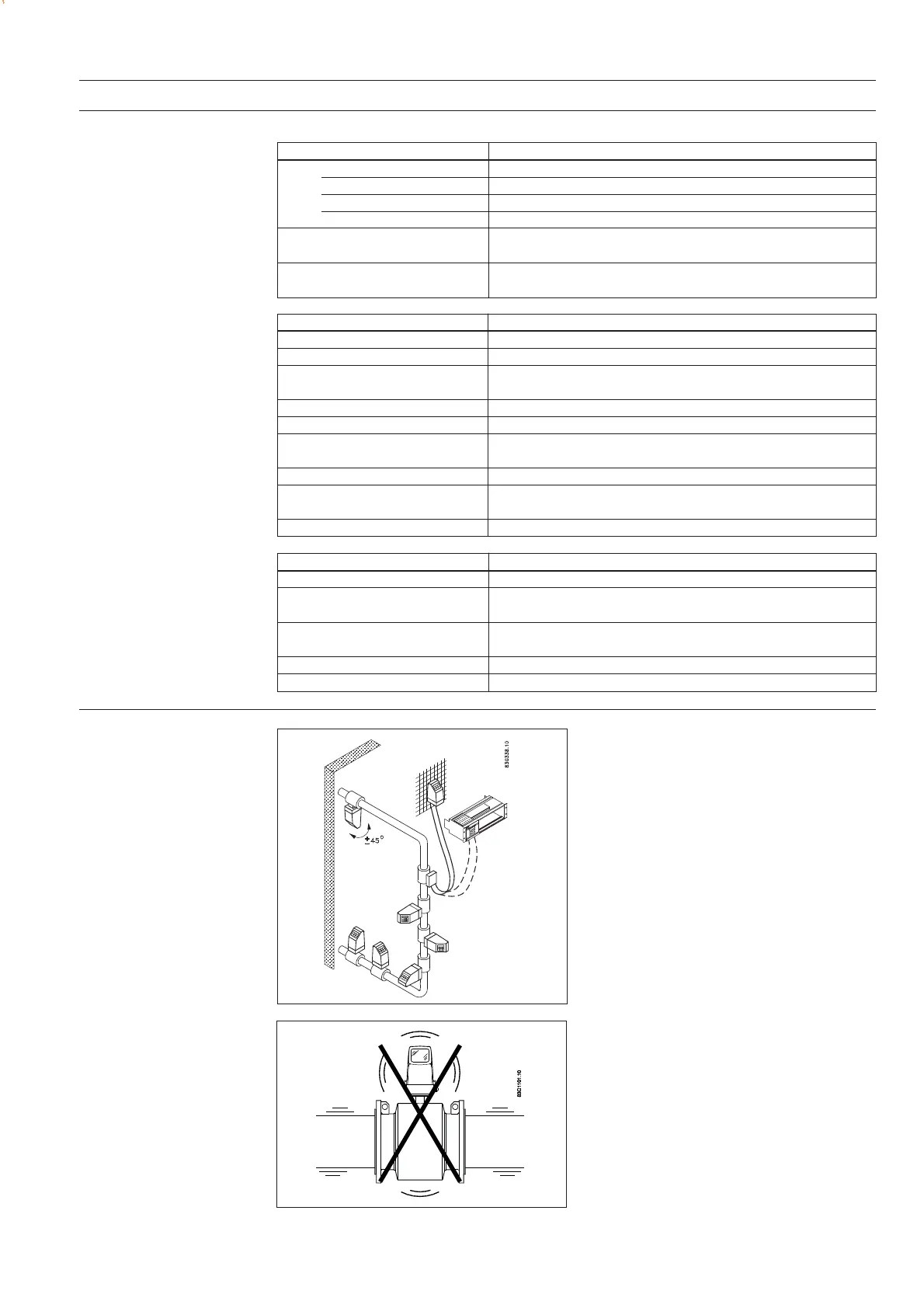

3.3

Installation conditions

Reading and operating the flowmeter is possi-

ble under almost any installation conditions

because the display can be oriented in relation

to the sensor. To ensure optimum flow mea-

surement, attention should be paid to the fol-

lowing:

Loading...

Loading...