45

SITRANS F M

5. Installation of sensor

MAG 3100

(PTFE liner and PFA)

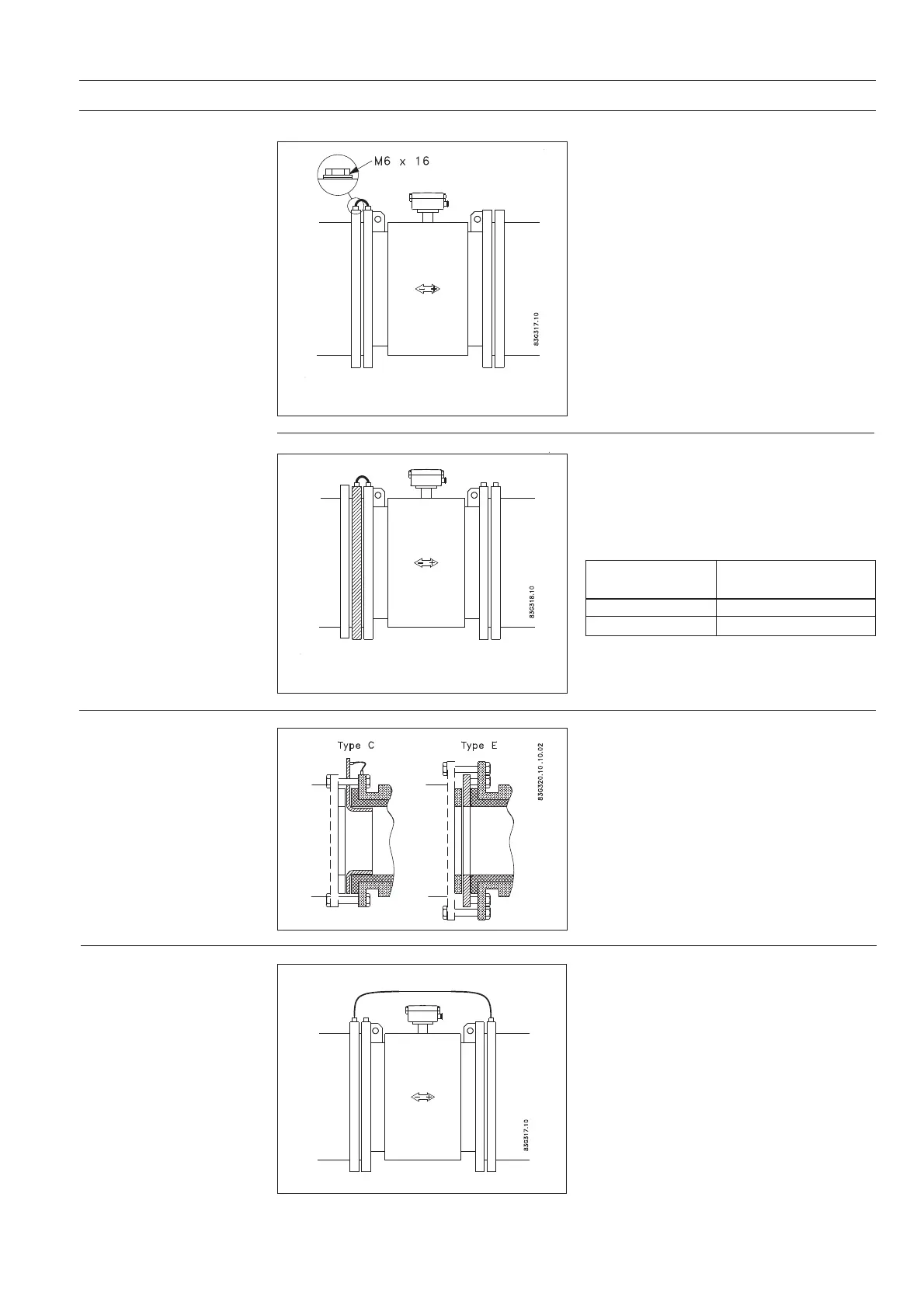

Electrically conductive piping

Use an earth strap on one side.

Potential equalization, electrically conductive

pipe

Non-conductive piping

Use an earthing flange. Place the flange between

flowmeter and the adjacent pipe flange.

Selection of earthing flange depends on the

medium, liner material and application, see

figure.

Special attention must be given to systems with

cathodic protection.

Compact installation:

The transmitter must be supplied through an

isolation transformer. The terminal "PE" must

never be connected.

Remote installation:

The screen must only be connected at the

sensor end via a 1.5 μF condensator. The

screen must never be connected at both ends.

Isolated sensor:

If above mentioned connections are unaccept-

able, the sensor must be isolated from the pipe

work.

The bolts must be isolated from pipe.

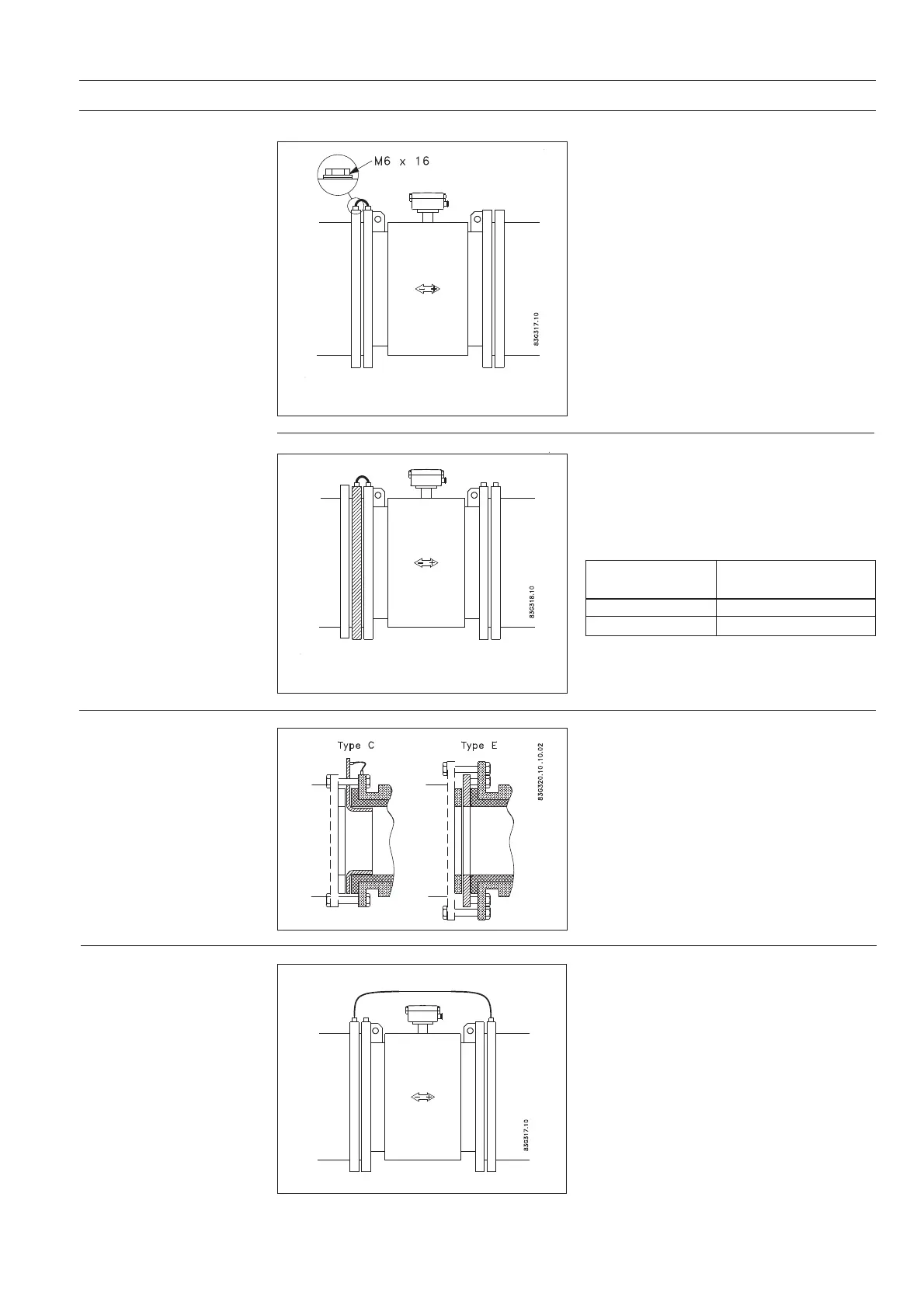

Liner Suitable

material earthing flange

PTFE Type E

PFA Flat ring

Type of earthing flange depending on liner

material

With abrasive liquids, flowmeter inlet protection

may be necessary. Here type C and E earthing

flanges are used.

Type C (for all liners except PTFE and PFA) is

clamped between the flanges.

Type E (for PTFE liner only) is fitted to the

flange.

Flat ring (for PFA liner only) is fitted to the

flange.

When using an earthing flange, gaskets must

always be used between the adjacent pipe

flange and the earthing flange.

5.2

Inlet protection MAG 3100

5.3

Cathodic protected piping

Loading...

Loading...