46

SITRANS F M

6. Installation of transmitter

6. Installation of

transmitter

6.1

Compact installation

MAG 5000 and MAG 6000

Compact polyamide

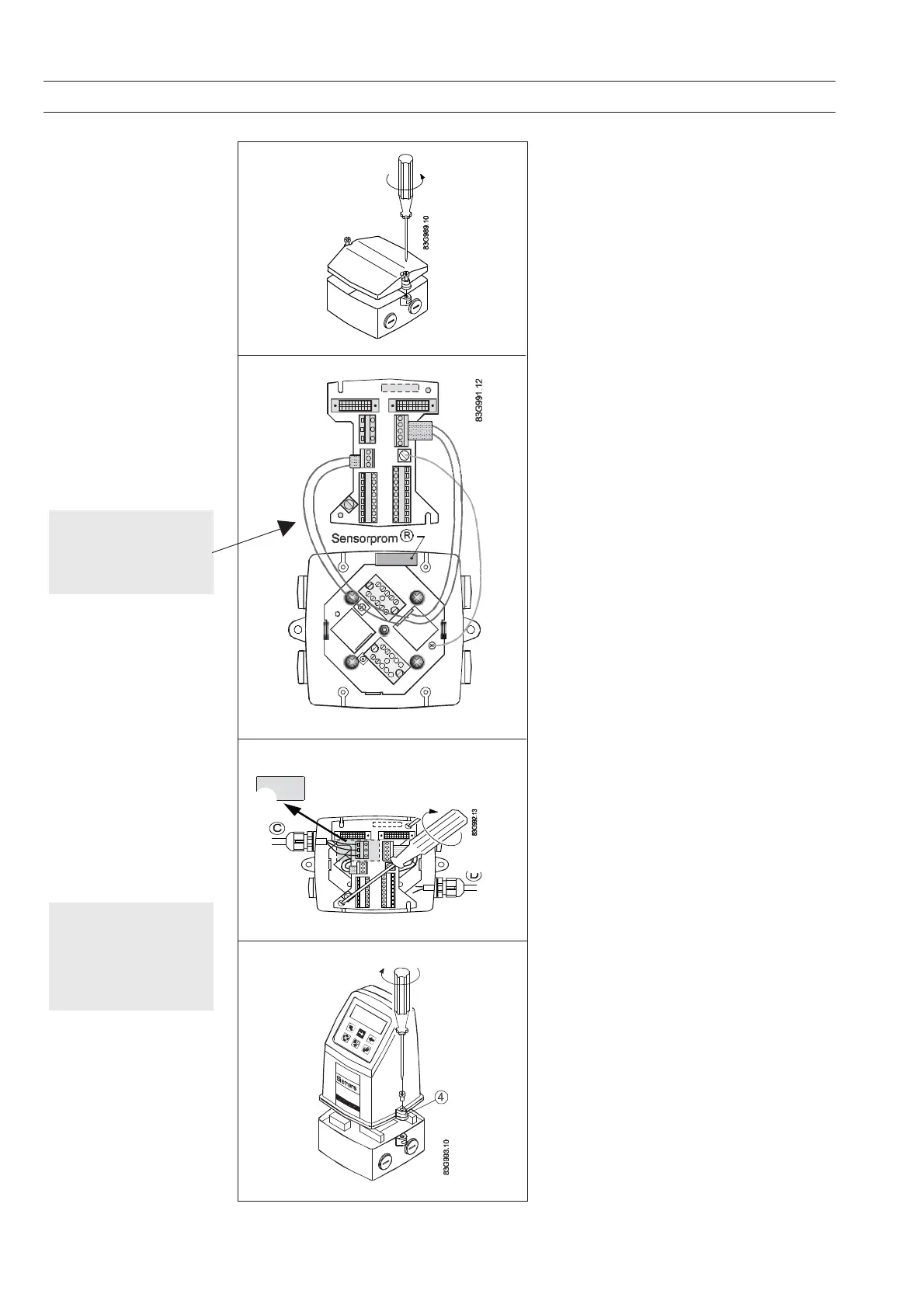

Step 1

Remove and discard the terminal box lid of the

sensor.

Fit the M20/½NPT cable glands for the supply

and output cables.

Step 2

Remove the two black plug assemblies for coil

and electrode cables in the terminal box and

connect them to their corresponding terminal

numbers on the connection board.

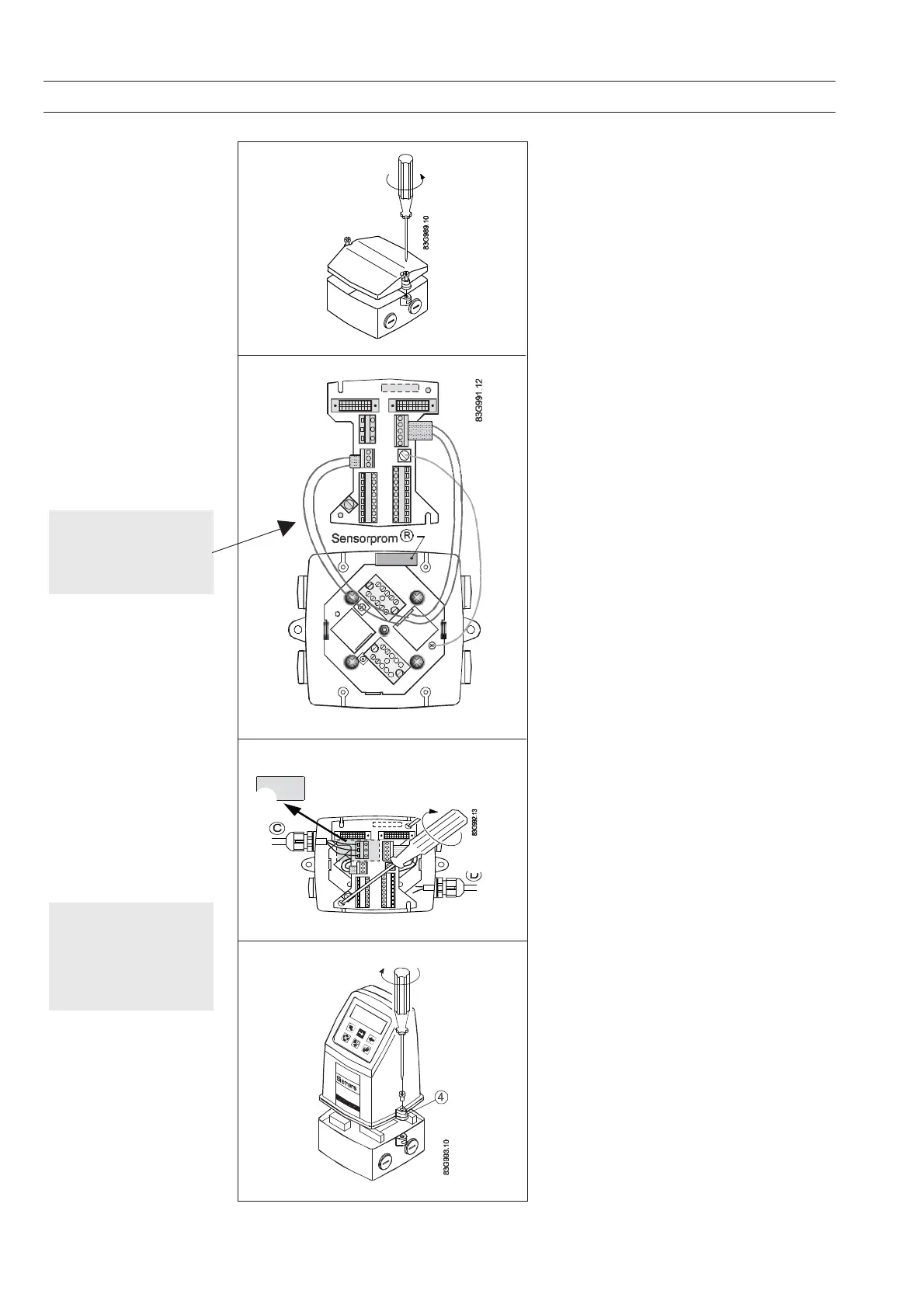

Step 3

Connect earth wire on connection board to

bottom of connection box.

Connect the 2 pin connector and 3 pin connector

as shown.

Note

In earlier version the 3 pin connector was a 5 pin

connector.

Step 4

Mount the connection plate in the terminal box.

The SENSORPROM

®

unit connections will be

established automatically when the connection

plate is mounted in the terminal box.

Note

Check that your connection board lines up with

the SENSORPROM

®

unit, if not, move the

SENSORPROM

®

unit to the other side of the

terminal box.

Step 5

Fit the supply and output cables respectively

and tighten the cable glands to obtain optimum

sealing.

Please refer to the wiring diagram in chapter 7

for the electrical connections.

Mount the transmitter on the terminal box.

Note

System will not register

flow if black plugs are not

connected to connection

board

Caution

Exposing the transmitter to

direct sunlight may

increase the operating

temperature above its

specified limit, and

decrease display visibilty

Loading...

Loading...