Page 174 MultiRanger 100/200 – INSTRUCTION MANUAL 7ML19981FB05

mmmmm

Parameters

Pumped Volume Totalizer (P622) [MR 200]

The Pumped Volume Totalizer is a MultiRanger 200 feature only.

If the eight-digit totalizer display or a remote totalizer contact closure are desired, alter

the following parameters.

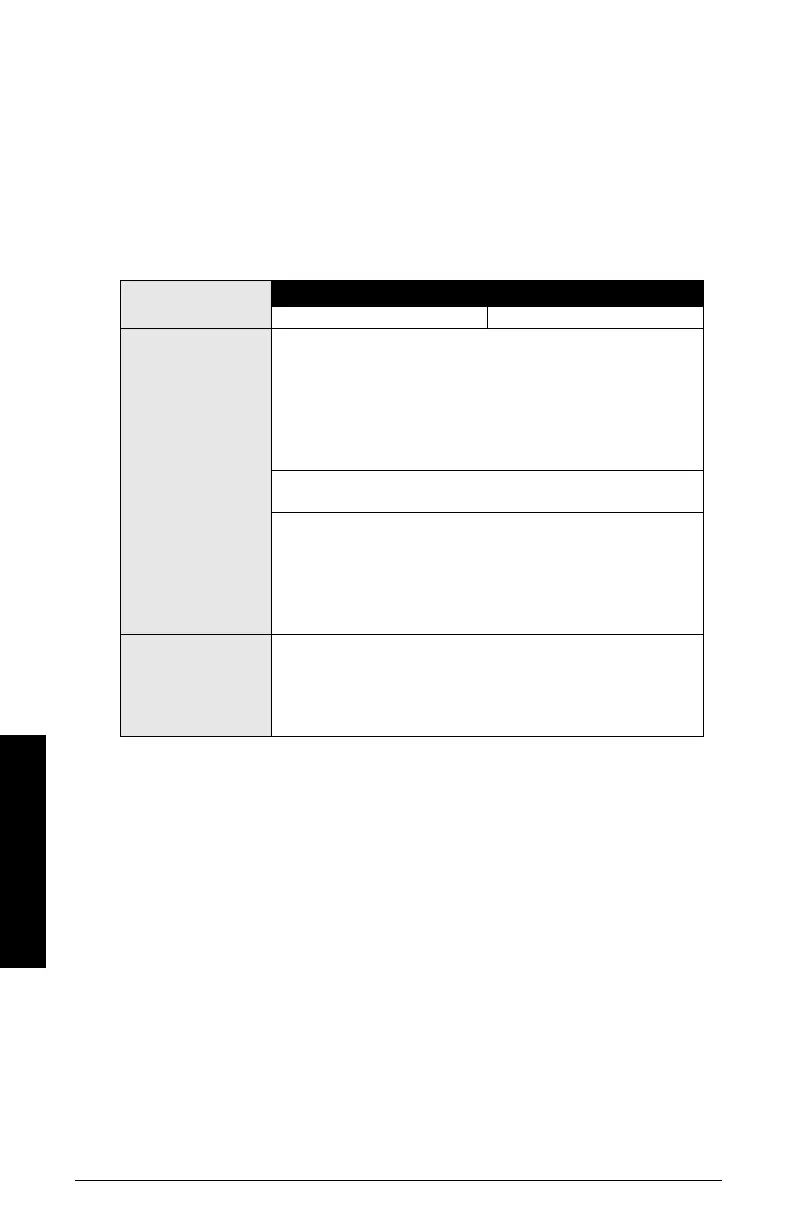

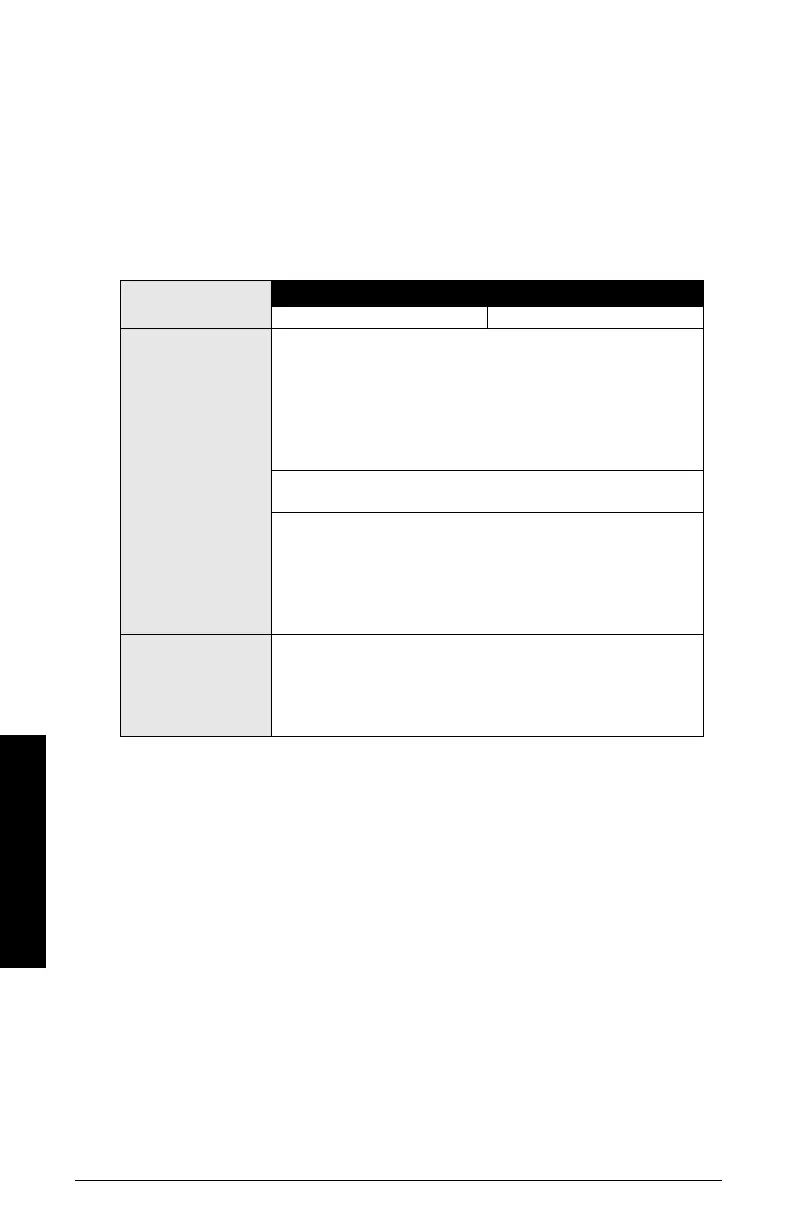

P622 Inflow / Discharge Adjust [MR 200]

The method used to calculate the volume pumped, for pumped total Operation (P001 = 7).

* or discharge

Primary Index

Single Point Model Dual Point Model

Global Transducer

Values

1 = inflow * / pump cycle

When the pump is off, the MultiRanger estimates the volume of inflow

by recording the rate at which the liquid level changes. When the

pump is operating, the estimated inflow volume is added to the

pumped volume total. When the pump stops, the pumped volume of

the previous pump cycle is added to the total volume pumped in the

totalizer.

2 = inflow * ignored

Inflow is assumed to be 0 while pumps are running.

3 = inflow * / rate (preset)

Volume pumped is adjusted for inflow. Inflow rate is estimated by

assuming that the rate calculated (P708) just prior to the start of the

pump cycle remained constant during the pump cycle. Inflow rate is

averaged using rate filter (P704), rate update time (P705) and rate

update distance (P706) to control how the average rate is calculated.

Related

•P001 Operation

• P704 Rate Filter

• P705 Rate Update Time

• P706 Rate Update Distance

• P708 Volume Rate Display

Loading...

Loading...