09.2008 Communication / PROFIBUS

Siemens AG 6SE7087-6QX70 (Version AK)

SIMOVERT MASTERDRIVES Compendium Motion Control 8.2-93

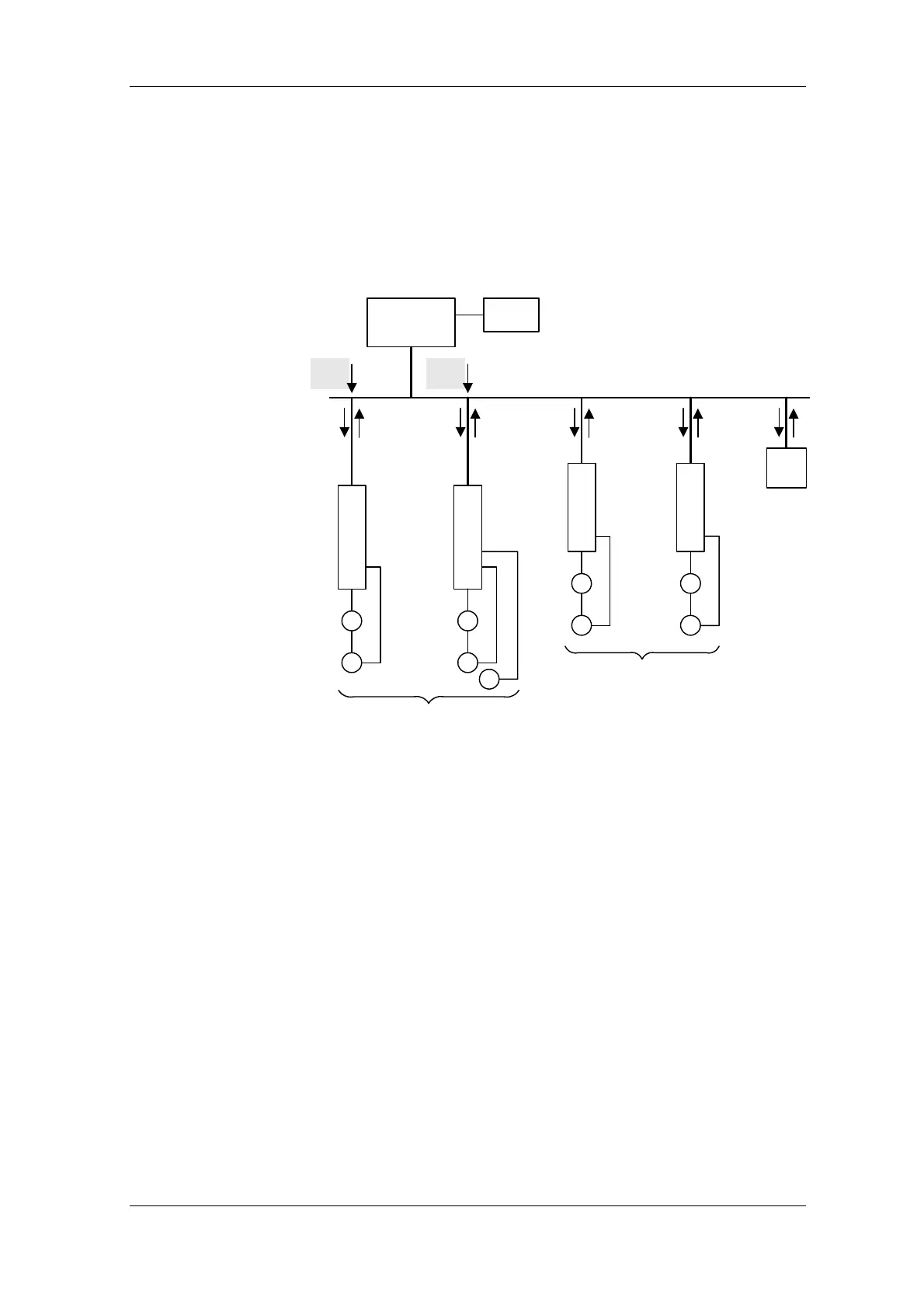

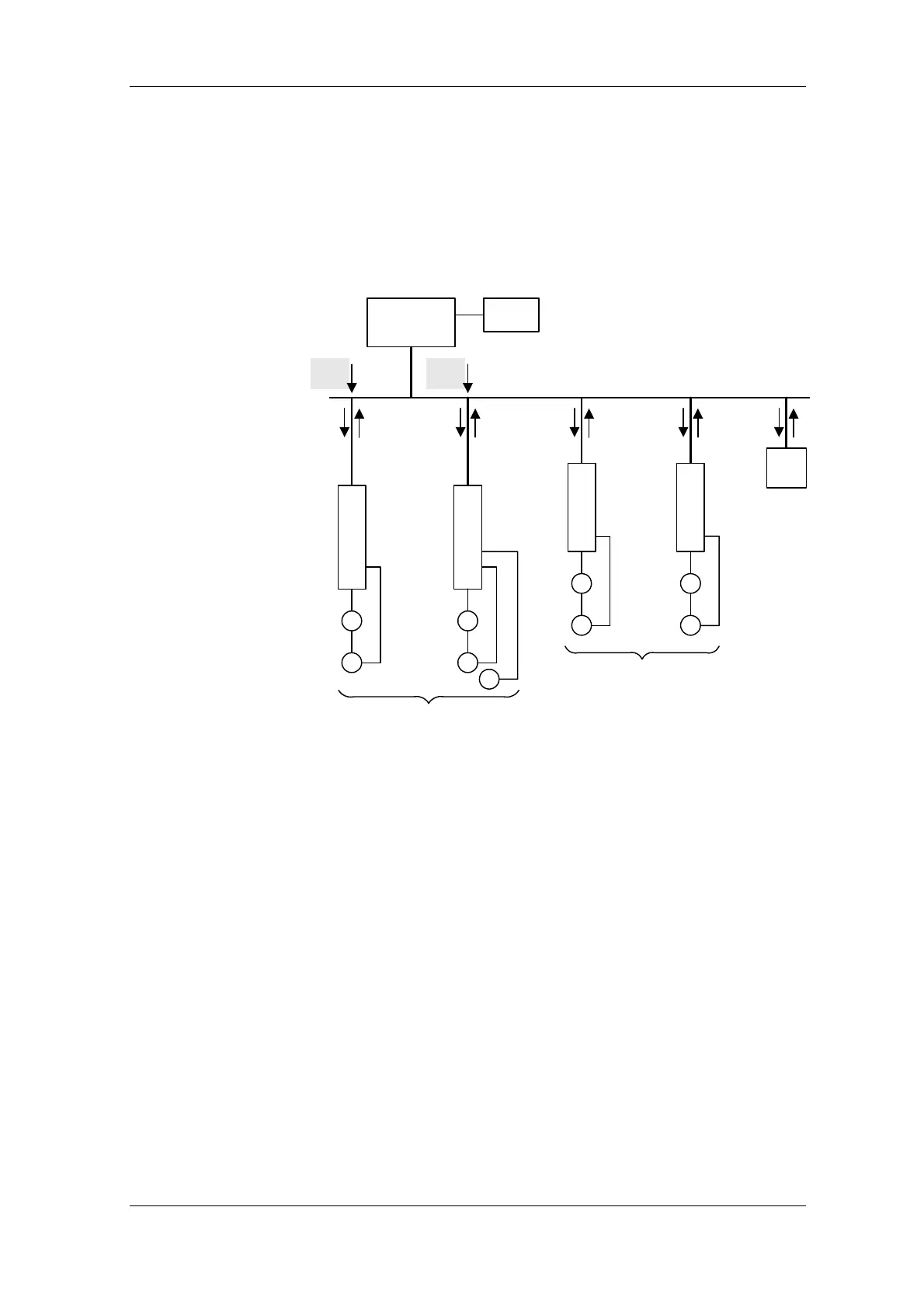

Clock synchronous monomaster operation (main application case)

With this operation the drives make high demands on time synchronism

at the bus. Through an isochronously transmitted global control the

master class-1 (e.g.SIMOTION) passes on clock pulse information to the

slaves (MASTERDRIVES), which synchronise themselves with this

pulse.

PLC, NC, PC

PU, OP

DPM1 (DPM2)

Clock

pulse

n

set

n

act

D

R

I

V

E

Slave

M

G

Clock

pulse

n

act

D

R

I

V

E

Slave

M

G

n

act

x

act1,2

x

act3,4

G

PROFIdrive drives (new)

e.g. synchronous closed-loop speed

control

PROFIBUS-DP

n

set

D

R

I

V

E

Slave

M

G

Pos.

select

set

Pos.sel.

act

n

act

D

R

I

V

E

Slave

M

G

PROFIdrive drives

Closed-loop speed

control

Positioning

A

I / O

Slave

E

other I/O

Fig. 8.2-30 Clock synchronous monomaster operation (DPM1)

The times for the setpoint transfer and actual value recording of the

slaves and the time of the control by the higher-level master can take

place through time parameters. The time parameters relate to the clock

pulse.

In the DP cycle there must be sufficient time for the following

communication elements:

♦ cyclical data exchange with all slaves on the bus

♦ a non-cyclical data channel (DPV1)

♦ telegram repeats

♦ diagnosis request

A local control device (PU, OP) at the DPM1 must communicate with the

slaves via the DPM1 master.

Loading...

Loading...